-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

plastic mesh sleeve

The Versatility and Benefits of Plastic Mesh Sleeves

In today's world, where efficiency and convenience are valued more than ever, innovative materials play a crucial role in various applications. Among these materials, plastic mesh sleeves have emerged as a favored solution in numerous industries, ranging from agriculture to manufacturing. This article delves into the nature, applications, and benefits of plastic mesh sleeves, highlighting their significant role in enhancing productivity and sustainability.

What Are Plastic Mesh Sleeves?

Plastic mesh sleeves are flexible, net-like tubes made from durable plastic materials such as polyethylene or polypropylene. These sleeves are designed with small openings that allow for breathability and visibility while providing a protective barrier. The construction of plastic mesh sleeves allows them to be lightweight yet strong, making them ideal for various applications where protection without bulk is necessary.

Applications of Plastic Mesh Sleeves

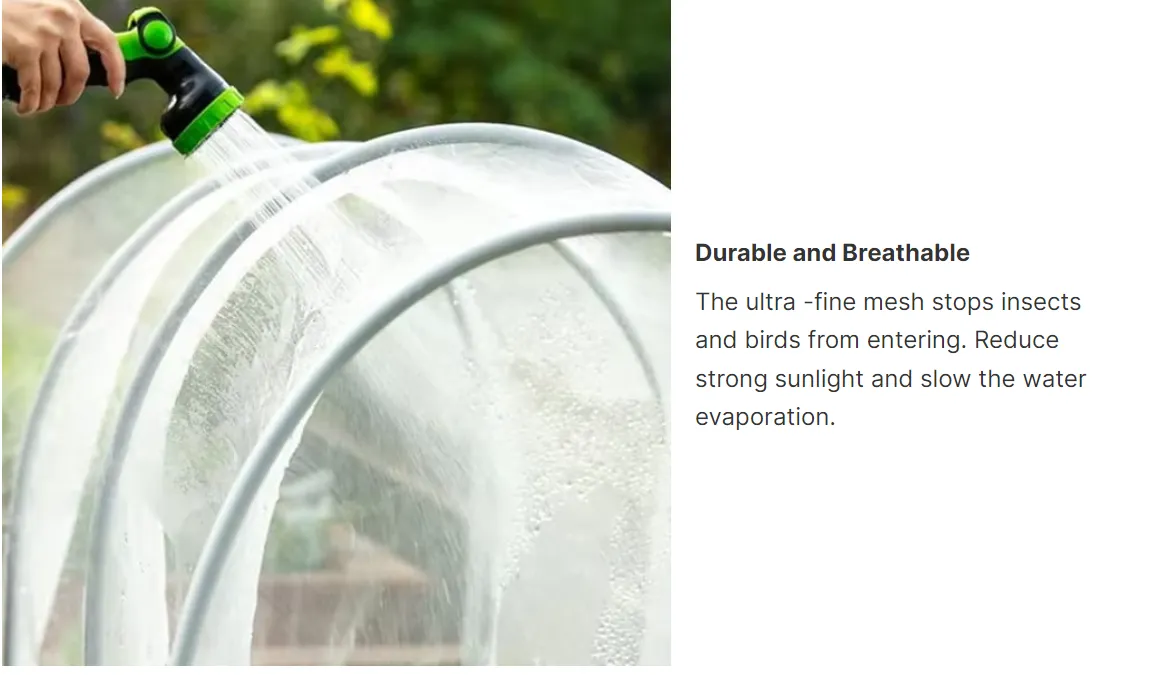

1. Agricultural Use One of the most notable uses of plastic mesh sleeves is in agriculture. Farmers often utilize these sleeves to protect young plants and crops from pests and harsh weather conditions. The mesh design allows sunlight and moisture to penetrate while keeping unwanted critters at bay. Additionally, these sleeves can be used to support plant growth, providing a sturdy structure to prevent bending or breakage during storms or high winds.

2. Packaging and Shipping In the realm of packaging, plastic mesh sleeves serve as an excellent solution for securing products. They are commonly used to bundle items such as fruits, vegetables, and other goods. The breathable nature of mesh material helps to keep produce fresh by allowing air circulation, reducing the risk of spoilage. Furthermore, their transparency allows for easy identification of contents, enhancing the efficiency of inventory management in warehouses and retail.

3. Automotive and Industrial In manufacturing settings, plastic mesh sleeves play a vital role in protecting sensitive components. They can be used as protective covers for cables and wires, reducing the risk of abrasion and damage that can occur during transportation or operation. This application is crucial in automotive industries, where the integrity of wiring systems is paramount for safety and functionality.

plastic mesh sleeve

4. Crafts and DIY Projects The versatility of plastic mesh sleeves makes them popular among DIY enthusiasts and crafters. They can be used creatively in various projects, from home decor to educational crafts, allowing individuals to explore their creativity while utilizing a practical material. The lightweight nature of mesh helps in creating intricate designs without adding unnecessary weight or bulk.

Benefits of Plastic Mesh Sleeves

1. Durability One of the primary advantages of plastic mesh sleeves is their durability. Resistant to environmental factors such as moisture, UV rays, and temperature fluctuations, these sleeves maintain their integrity and performance over an extended period, making them a cost-effective choice for various applications.

2. Eco-Friendly Options With an increasing emphasis on sustainability, many manufacturers are now producing biodegradable and recyclable plastic mesh sleeves, which offer an eco-friendly alternative to traditional materials. This shift not only reduces environmental impact but also meets the growing consumer demand for sustainable products.

3. Cost-Effectiveness Plastic mesh sleeves are typically more affordable than other protective materials, particularly when considering their durability and functionality. Their lightweight nature also means lower shipping costs, further enhancing their appeal to businesses looking to optimize their expenses.

4. Customization These sleeves can be easily customized in terms of size, color, and design to meet specific requirements. This adaptability allows businesses to brand their products effectively while ensuring that the protective features align with their operational needs.

Conclusion

Plastic mesh sleeves are a quintessential example of how innovative materials can address a range of practical challenges across industries. From agricultural applications that protect crop yields to industrial uses that safeguard sensitive components, the versatility of plastic mesh sleeves is undeniable. As they continue to evolve with a focus on sustainability and customization, these sleeves are poised to play an even more significant role in driving efficiency and environmental responsibility in the years to come. Whether for professional or personal use, embracing plastic mesh sleeves can lead to smarter solutions that benefit both the user and the planet.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025