-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

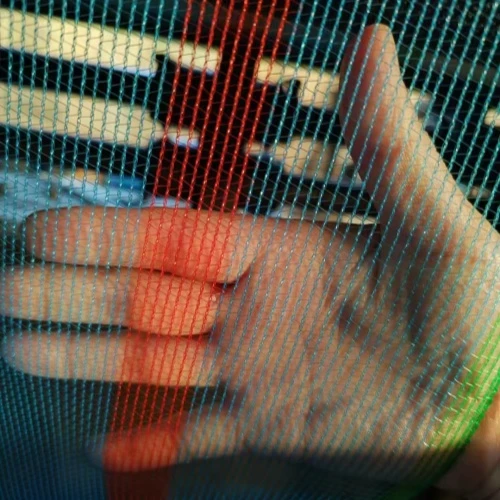

plastic mesh sleeve

The Versatility of Plastic Mesh Sleeves An Insight into Their Applications and Benefits

In today’s manufacturing and packaging industries, the demand for innovative materials that enhance efficiency and productivity has never been higher. One such material that has emerged as a game-changer is the plastic mesh sleeve. Lightweight, durable, and versatile, plastic mesh sleeves have found applications across various sectors, from agriculture to automotive, offering solutions that address specific challenges faced by businesses.

What is a Plastic Mesh Sleeve?

Plastic mesh sleeves are tubular structures made from interwoven plastic filaments, creating a breathable mesh design. These sleeves come in various sizes and thicknesses, which makes them adaptable for a wide range of uses. Their design allows for air circulation while providing protection, making them ideal for wrapping and bundling different objects.

Applications of Plastic Mesh Sleeves

1. Agriculture One of the most significant applications of plastic mesh sleeves is in agriculture. Farmers use them to protect young plants and vegetables from pests and environmental factors. The mesh design allows sunlight and moisture to penetrate while keeping harmful insects at bay. They are also beneficial for supporting climbing plants or providing trellis systems, helping to optimize growth.

2. Packaging In the packaging industry, plastic mesh sleeves are used extensively to package products ranging from fruits and vegetables to fragile items. The mesh provides cushioning and protection during transportation, minimizing the risk of damage. Additionally, the breathable nature of the material helps prevent moisture buildup, which can lead to spoilage in perishable goods.

3. Construction In the construction sector, plastic mesh sleeves are utilized for bundling and protecting tools, pipes, and wires. Their strength and flexibility allow for secure wrapping, thus keeping the materials organized and safe from external damage. They are also used in scaffolding and mesh reinforcement for various building projects.

4. Automotive The automotive industry employs plastic mesh sleeves for wiring harnesses and cable management. By protecting wires from abrasion and insulation breakdown, these sleeves enhance the longevity and reliability of automotive electrical systems. Their lightweight nature contributes to overall vehicle weight reduction, which is a critical factor in modern automotive design.

plastic mesh sleeve

5. Sports and Fitness Plastic mesh sleeves are also popular in sports equipment packaging and transport. They protect items like tennis rackets and golf clubs from scratches and impacts while allowing air circulation to prevent moisture buildup, which can damage sensitive materials.

Benefits of Using Plastic Mesh Sleeves

The benefits of plastic mesh sleeves extend beyond their versatility. They offer several advantages that make them an attractive choice for businesses

- Durability Made from high-quality plastics, these sleeves are resistant to wear and tear, ensuring long-lasting performance even in challenging environments. - Lightweight Their lightweight nature means that they do not add significant bulk to packaged products, making them an economical choice for shipping and transportation.

- Cost-Effective By providing protection and enhancing efficiency, plastic mesh sleeves can lower overall costs associated with damage and waste.

- Eco-Friendly Options Many manufacturers are now producing biodegradable or recyclable mesh sleeves, aligning with global efforts to reduce plastic waste and promote sustainability.

Conclusion

The rise of plastic mesh sleeves in various industries showcases their innovative design and functional benefits. From agriculture to packaging and construction, these sleeves offer effective protection while enhancing efficiency and safety. As industries continue to seek sustainable and cost-effective solutions, the role of plastic mesh sleeves is likely to expand, solidifying their place as a crucial component in modern manufacturing and packaging processes. Embracing this versatile solution can lead businesses toward greater innovation and success in today’s competitive landscape.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025