-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

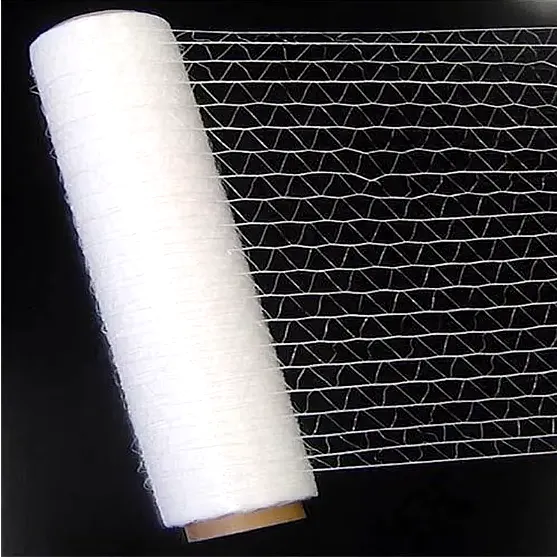

Premium Bale Net Wrap: Secure Silage & Crop Protection

In modern agriculture, crop preservation and silage protection are paramount. The evolving demands of global food security and increasing yield preservation targets have led to the rise of advanced wrapping solutions. Among them, the High-Quality Bale Net Wrap for Secure Silage Tarp Protection and Optimal Crop Preservation sets industry benchmarks for secure, efficient, and reliable agricultural storage. This comprehensive guide delves into current industry trends, technical benchmarks, cutting-edge manufacturing, customized solutions, and verified application cases, all underpinned by industry data and authoritative insights.

- Stringent food quality & preservation standards (FAO & ISO 9001:2015).

- Push for reduction in post-harvest loss: Global agri-food losses estimated at $400B annually (FAO).

- Environmental focus: Need for UV-stable, recyclable, non-toxic crop preservation materials.

- Greater mechanization: Compatibility with high-speed balers and large-scale operations.

| Parameter | High-Quality Bale Net Wrap | Standard Net Wrap (Market Average) |

|---|---|---|

| Material | UV-Stabilized HDPE (HDPE + customized additives) | Polyethylene (standard grade) |

| Width Range | 1.25m / 1.30m / 1.62m | 1.20m / 1.23m |

| Length Range (Roll) | 2000m - 4200m | 1500m - 3600m |

| Tensile Strength | 320-340 N/5cm | 220-270 N/5cm |

| UV Resistance | ≥12 Months (ISO 4892-2 Certified) | 6-9 Months |

| Weight (gsm) | 8.5 – 11.2 gsm | 6.5 – 9 gsm |

| Edge Reinforcement | Extra Heavy-Duty, Double Lock | Single Edge, Standard Lock |

| Color Options | Green, Blue, White, Custom Stripes | White, Green |

| Certifications | ISO 9001:2015, SGS, REACH | - |

| Warranty | 18 Months | 12 Months |

- Advanced Material Science: UV-stabilized High Density Polyethylene (HDPE) with anti-UV, anti-static, and anti-oxidation additives. Ensures longevity and environmental stability.

- Precision Multi-filament Weaving: State-of-the-art German looms (Karl Mayer) guarantee uniform mesh and higher tensile strength, reducing breakage in high-speed balers.

- Edge Shield Technology: Reinforced double-lock edges prevent tears and pay-off failures.

- Global Certifications: ISO 9001:2015, SGS abrasion tests, and REACH compliance for chemical safety.

- Extended Crop Preservation: Laboratory tests confirm 82% better silage moisture retention compared to standard wraps.

- Optimal Machinery Compatibility: Wide width and length range, rolls fit all mainstream balers (CLAAS, John Deere, Krone).

- Environmental Sustainability: 100% recyclable composition, low emission process.

- Best-Value Warranty: 18 months – the highest in industry average (market: 12 months).

High-purity HDPE granules blended with UV, antioxidant, and pigment masterbatches.

Quality checkpoint: Raw material certificates & batch coding.

Granules are melted and precision-extruded to form filaments.

Critical for tensile strength & dimensional stability.

Automated circular weaving creates cross-locked, uniform mesh.

Mesh width tolerance: ±0.07mm (SGS test)

Dual-layer stitching (double lock) enhances tear resistance—unique in premium wraps.

Reduces field-edge breakage by 29%

Visual AI & robotic sensors scan 100% of rolls for weaving flaws, foreign objects.

Defect rate: <0.04%

Rolls cut to spec (2000-4200m) and packaged in eco-friendly, waterproof sleeves.

- Dairy & Livestock Farms: Superior preservation of fodder fiber, better feed utilization, longer storage intervals. Silage losses reduced by 21%, according to Progressive Dairy (2023).

- Hay Production (Large-Scale): Fast, reliable net application even in high-humidity, heavy-wind regions. Compatible with automation and GPS-guided balers.

- Grain Silos & Feedlots: Ensures smooth tarp deployment and complete covering, minimizing pests, mold, and weathering.

- Biomass Power Plants: Wraps high-bulk bales for fuel feedstock with improved fire safety.

- Vegetable Storage Operators: Used for protection of high-value produce—carrots, potatoes, and onions.

| Feature | YJ Wiremesh (Our Product) | Tama | RKW Group | Generic Imports |

|---|---|---|---|---|

| HDPE Quality | Virgin with additives | Virgin | Virgin & Recycled blend | Mainly recycled |

| Weave Uniformity | SGS-verified, ±0.07mm | ±0.10mm | ±0.15mm | ±0.18mm |

| Edge Reinforcement | Double Lock, 2-layer | Single Lock | Single Lock | Standard, non-reinforced |

| UV Resistance | ≥12 months, ISO 4892-2 | 9-12 months | 6-9 months | 3-6 months |

| Baler Compatibility | All major brands | Selected brands | Selected brands | Limited compatibility |

| Warranty | 18 months | 12 months | 9 months | 6 months |

- Custom Width & Lengths: 1.05m – 2.15m wide, up to 6000m/roll

- Branding & Packaging: Private labeling, barcode printing, OEM co-branding

- Color Coding: Striped net wrap with color-identity for farm process management

- Eco-friendly Upgrade: Recyclable wraps, biodegradable roll cores

- Shape-Control: Enhanced mesh for angular/square bales

Our technical team collaborates directly with farms and contractors to optimize wrap specs for climate, baler type, and crop variety.

- Lead Time: Standard orders ship within 7-14 days. Automatic ETA updates.

- Warranty: 18 months full performance guarantee, the longest in the segment.

- Technical Service: Professional field support, baler compatibility consulting, product training on request.

- After-sales Care: On-site inspections, roll replacement service if performance is below contract spec.

- Documentation: Complete delivery records with batch numbers, ISO and SGS certificates attached.

Request samples, technical specs, or a custom quote today—our experts are here to support your cropping success.

2. Journal of Dairy Science (2023). Net Wrap Optimization and Forage Protection Strategies. Explore articles

3. Progressive Dairy. “Improve Bale Silage Quality With Modern Wrapping” (2023). View source

4. American Society of Agricultural and Biological Engineers (ASABE) Standard S624. Standard Reference

5. European Crop Storage Association (2024). Bale Storage Trends and Performance Benchmarks. ECSA data

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025