Premium Insect Proof Netting for Gardens & Farms | Effective Protection

Strategic Pest Management with Advanced Netting Solutions

In contemporary agriculture and residential environments, the imperative for effective pest control without reliance on harmful chemicals has intensified. The market for physical barrier solutions, particularly high-performance insect proof net, is experiencing robust growth. This demand is driven by stricter environmental regulations, consumer preference for organic produce, and the increasing resistance of pests to conventional pesticides. Modern insect netting represents a sophisticated engineering solution, blending material science with precise manufacturing to create durable, effective barriers against a wide spectrum of pests.

The global agricultural netting market, which includes products like black insect netting and nylon insect mesh, is projected to reach significant valuation, growing at a compound annual growth rate (CAGR) of over 6% in the coming years. This growth is indicative of the essential role these materials play in safeguarding crops, enhancing yields, and supporting sustainable farming practices worldwide. From large-scale commercial greenhouses requiring extensive agricultural insect net installations to individual gardens utilizing insect proof garden netting, the technology continues to evolve, offering improved performance and longevity.

The Precision Engineering Behind Insect Proof Net Production

The manufacturing of high-quality insect proof net is a multi-stage, precision-driven process, ensuring optimal performance and durability in diverse applications. This meticulous production flow guarantees that the final product meets stringent industry standards and provides long-term protection against pests.

Manufacturing Process Flow:

- Material Selection & Preparation: The foundation of a superior insect proof net lies in the selection of raw materials. Typically, high-density polyethylene (HDPE) or premium nylon granules are chosen for their exceptional tensile strength, UV resistance, and chemical inertness. These polymers are compounded with specialized UV stabilizers to significantly extend service life under intense solar radiation, alongside precise colorants for aesthetic or functional purposes (e.g., blue for specific light spectrum manipulation).

- Extrusion of Monofilaments: Selected granules are fed into an extruder, where they are melted at controlled temperatures and forced through a spinneret die. This process creates continuous, uniform monofilaments (single strands) of specified diameter. Consistency in filament diameter is critical for achieving a uniform mesh structure and optimal air permeability.

- Drawing and Stretching: The extruded monofilaments undergo a multi-stage drawing process, where they are stretched under tension. This molecular orientation process aligns the polymer chains, dramatically increasing the tensile strength and reducing elongation, thereby enhancing the net's resistance to tearing and deformation.

- Weaving or Knitting: The drawn monofilaments are then fed into specialized weaving or knitting machines. For agricultural applications, a Leno weave is often preferred due to its superior strength and stability, where warp yarns are twisted around weft yarns to prevent unraveling and maintain mesh integrity even if a strand breaks. For window screens, a plain weave can also be utilized. The mesh count (e.g., 16x13 or 20x20 per square inch) is precisely controlled at this stage.

- Heat Setting and Finishing: After weaving, the netting undergoes a heat-setting process. This thermal treatment stabilizes the mesh structure, removes internal stresses, and prevents shrinkage or distortion over time. Further finishing processes may include anti-static treatments or additional UV coatings.

- Quality Control & Testing: Throughout and post-production, rigorous quality control measures are implemented. Products are tested against international standards such as ISO 9001:2015 for quality management, ASTM D5034 for tensile strength, and ASTM D638 for elongation. Key parameters verified include mesh uniformity, breaking strength, tear resistance, UV degradation resistance (using accelerated weathering tests), and air permeability. This ensures the insect proof net performs reliably under intended operational conditions.

- Cutting, Rolling & Packaging: The finished netting is precisely cut to specified dimensions, carefully rolled, and packaged to prevent damage during transit and storage.

The target industries for these advanced netting solutions are primarily agricultural (greenhouses, nurseries, orchards), horticultural, and residential (window screens, porch enclosures). The typical service life for a well-manufactured, UV-stabilized insect proof net ranges from 3 to 7 years, significantly reducing the need for frequent replacement and providing long-term value.

Technical Specifications and Product Parameters

Understanding the precise technical specifications of an insect proof net is paramount for selecting the appropriate solution for a given application. Mesh count, material composition, and treatment parameters directly influence its efficacy and longevity.

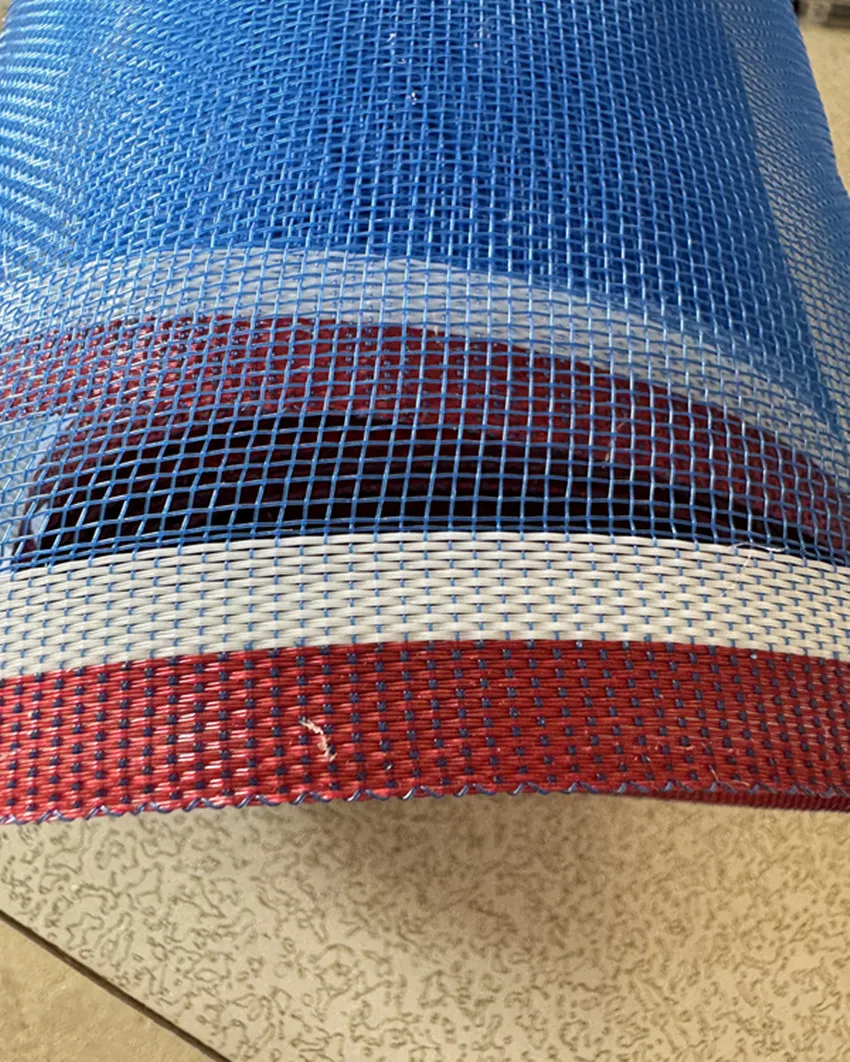

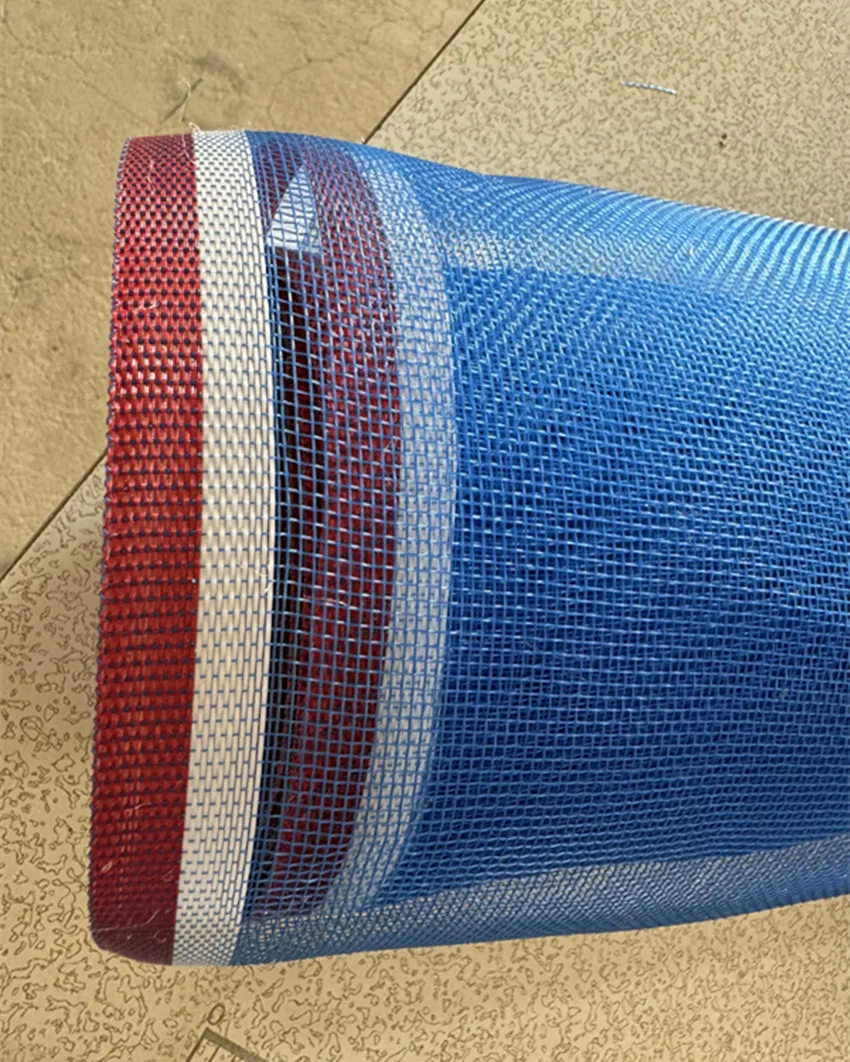

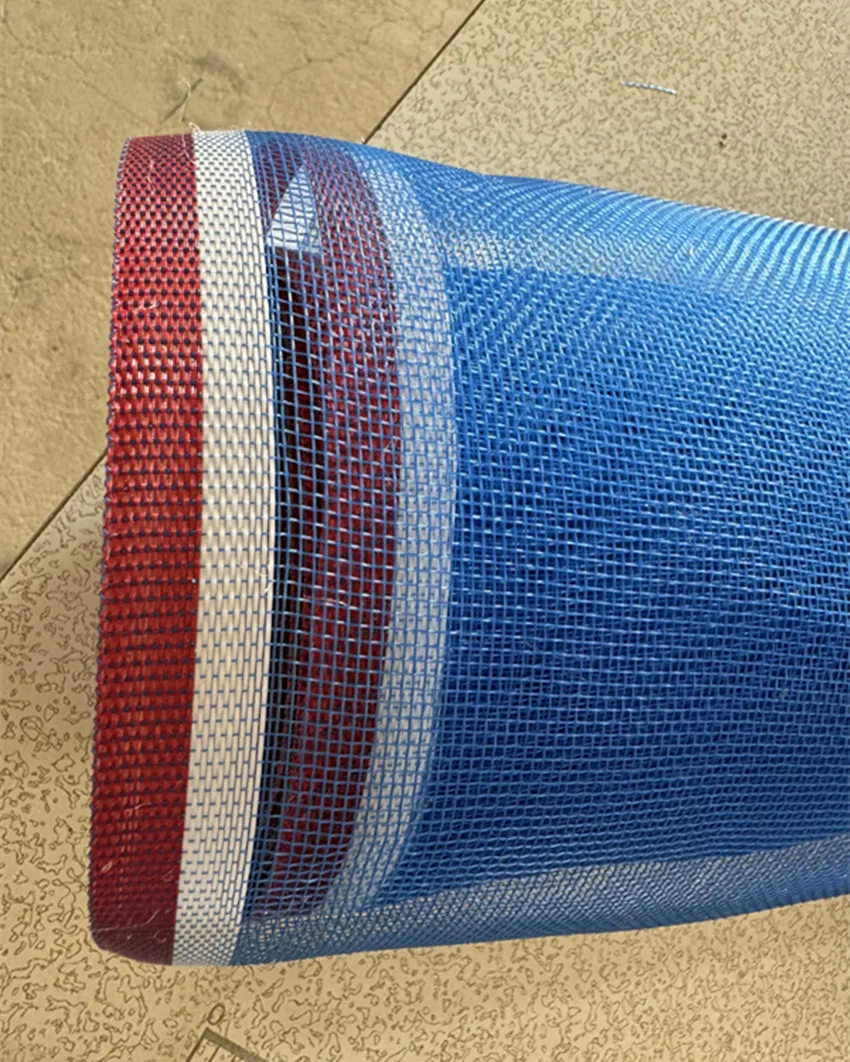

Product Spotlight: Blue Insect-Proof Net Window Screen 16✖13

Our Blue Insect-Proof Net Window Screen, with a 16✖13 mesh configuration, exemplifies high-performance residential and light agricultural netting. This specific mesh density offers an optimal balance between insect exclusion and airflow, critical for maintaining comfortable indoor environments or breathable greenhouse conditions while protecting against a wide array of common pests.

| Parameter | Specification (Blue Insect-Proof Net 16x13) |

|---|---|

| Product Name | Blue Insect-Proof Net Window Screen |

| Mesh Count | 16 x 13 strands per inch (warp x weft) |

| Material | High-Density Polyethylene (HDPE) or Nylon |

| Yarn Diameter | ~0.25mm - 0.35mm (typical) |

| Color | Blue |

| UV Stabilization | 3-5% UV inhibitor content |

| Tensile Strength | > 300 N/5cm (ASTM D5034, typical) |

| Tear Resistance | > 80 N (ASTM D2261, typical) |

| Light Transmission | ~80-85% (for blue netting) |

| Pest Exclusion | Effective against mosquitos, flies, gnats, aphids, thrips, whiteflies, etc. |

| Standard Widths | 1m, 1.2m, 1.5m, 1.8m, 2m, 2.5m, 3m (customizable) |

| Roll Lengths | 30m, 50m, 100m, 200m (customizable) |

Diverse Application Scenarios of Insect Proof Netting

The versatility of insect proof net extends across various sectors, demonstrating its critical role in protective barriers. From intensive farming to residential comfort, these nets provide essential defense against insect-borne damage and disease vectors.

- Agricultural Greenhouses and Tunnels: The primary application for agricultural insect net is within controlled environment agriculture. Netting integrated into greenhouse vents, side walls, and doorways effectively prevents the entry of aphids, whiteflies, thrips, and other destructive insects, reducing crop damage and the reliance on chemical pesticides. This promotes healthier plant growth and higher yields, directly impacting the agricultural insect net price vs. benefit analysis.

- Orchards and Fruit Groves: Large-scale netting installations over fruit trees protect ripening produce from fruit flies, birds, and other pests, preventing pre-harvest losses. The use of specialized UV-stabilized nylon insect mesh ensures longevity in open-field conditions.

- Horticultural Nurseries: Young plants and seedlings in nurseries are particularly vulnerable to insect infestations. Protective netting safeguards these delicate crops, ensuring robust development before transplantation.

- Home Gardens and Allotments: For enthusiasts and small-scale growers, insect proof garden netting offers an organic method to protect vegetables, herbs, and fruits from common garden pests like cabbage white butterflies, carrot rust flies, and onion flies.

- Poultry and Livestock Enclosures: Netting can be used to cover openings in poultry houses, protecting birds from mosquitos and other biting insects that can transmit diseases. Similarly, it aids in maintaining hygienic conditions in other livestock shelters.

- Residential and Commercial Window Screening: Our Blue Insect-Proof Net Window Screen 16x13 is ideal for preventing mosquitos, flies, and other nuisance insects from entering homes, offices, and industrial facilities, enhancing comfort and hygiene. This type of black insect netting or blue netting provides effective barriers without significantly impeding visibility or airflow.

Technical Advantages and Performance Benefits

The strategic implementation of high-grade insect proof net offers a multitude of technical and operational advantages that contribute to enhanced productivity, sustainability, and cost-effectiveness in diverse applications.

- Superior Pest Exclusion: Precision-engineered mesh sizes, such as 16x13 or finer, physically block even the smallest insects (e.g., whiteflies, thrips, aphids) while allowing adequate air circulation. This physical barrier is often more effective and environmentally friendly than chemical deterrents.

- Enhanced Crop Health and Yield: By preventing insect infestations, netting reduces the incidence of pest-borne diseases and the need for pesticides. This leads to healthier plants, reduced stress, and ultimately, higher quality and quantity of produce. Data from controlled agricultural trials consistently show increased yields of 15-25% in crops protected by appropriate agricultural insect net.

- UV Stabilization and Longevity: Modern insect netting, particularly those made from HDPE or specialized nylon insect mesh, are heavily UV stabilized. This resistance to photodegradation ensures a service life of several years (typically 3-7 years), minimizing replacement costs and labor.

- Optimized Microclimate Control: While acting as a barrier, the netting also provides a degree of shade, reducing excessive solar radiation and maintaining a more stable temperature within enclosed spaces. This can contribute to energy savings by reducing the load on cooling systems in greenhouses.

- Chemical-Free Pest Management: The use of physical barriers aligns with organic farming principles and reduces environmental impact by eliminating the need for chemical sprays. This protects beneficial insects, pollinators, and the surrounding ecosystem, while also ensuring food safety.

- Corrosion Resistance and Durability: Unlike metal screens, polymer-based insect netting is inherently resistant to corrosion from moisture, agricultural chemicals, and pollutants. Its robust construction resists tearing and stretching, even under moderate mechanical stress.

Vendor Comparison and Material Considerations

When sourcing insect proof net, a critical analysis of vendor capabilities and product specifics is essential. Differentiation often lies in material quality, manufacturing precision, and commitment to international standards.

Key Factors in Vendor and Product Comparison:

- Material Quality: While most netting is HDPE or nylon, the quality of the virgin polymer, consistency of resin, and the percentage and type of UV stabilizers are paramount. Inferior materials lead to premature degradation and reduced service life.

- Mesh Uniformity and Accuracy: Precision in mesh count and aperture size directly impacts pest exclusion capabilities. Irregularities can create weak points or allow smaller pests to penetrate. Reputable manufacturers adhere to strict dimensional tolerances.

- Weave Strength and Stability: A robust weave structure (e.g., Leno weave) prevents unraveling and maintains structural integrity under tension and environmental stress. This is particularly crucial for large-scale agricultural insect net installations.

- Certifications and Testing: Vendors adhering to ISO 9001:2015 for quality management and providing verifiable test data (e.g., ASTM standards for tensile strength, UV resistance) offer greater assurance of product performance and reliability.

- Customization Capabilities: The ability to provide custom widths, lengths, specific mesh counts, and even colors (e.g., various shades of black insect netting or blue netting for light spectrum manipulation) is a significant advantage for specialized projects.

- Price vs. Performance (Agricultural Insect Net Price): While cost is a factor, prioritizing the lowest agricultural insect net price can be counterproductive if it compromises quality and leads to earlier replacement or inadequate pest control. A higher initial investment in a durable, high-performance net often results in lower total cost of ownership over its lifespan.

| Feature | Standard Netting (Generic) | Premium Insect Proof Net (e.g., YJ Wire Mesh) |

|---|---|---|

| Material Composition | Recycled PP/HDPE, minimal UV | Virgin HDPE/Nylon, 3-5% high-grade UV stabilizers |

| Mesh Uniformity | Variable, inconsistent aperture size | Highly consistent, precise mesh apertures |

| Weave Type | Simple plain weave, prone to unraveling | Leno weave or reinforced plain weave, high stability |

| UV Resistance (Service Life) | 1-2 years, rapid degradation | 3-7+ years, excellent resistance |

| Tensile/Tear Strength | Lower, susceptible to damage | High, robust against environmental stressors |

| Pest Exclusion Efficacy | Limited, inconsistent for smaller pests | Broad spectrum, highly reliable for target pests |

| Certifications | Often none or minimal | ISO 9001, internal QC reports, third-party tests |

Customized Solutions for Specific Demands

Recognizing that standard products may not suffice for every unique application, leading manufacturers offer bespoke solutions for insect proof net. Customization is crucial for optimizing performance in highly specific environmental or operational contexts.

Key areas of customization include:

- Mesh Size and Density: Tailoring the mesh count (e.g., from a coarser 10x10 to a very fine 20x20 or even 50x25) to target specific pest sizes while balancing airflow and light transmission requirements. For instance, extremely fine mesh is needed for thrips or whiteflies, whereas a more open mesh might suffice for larger beetles.

- Material Composition: While HDPE and nylon are standard, specific applications might benefit from enhanced chemical resistance, flame retardancy, or even biodegradable options for temporary installations.

- Dimensions: Manufacturing netting in exact widths and lengths to minimize waste and facilitate seamless installation in large greenhouse complexes, shade structures, or custom window frames.

- Color and Opacity: Different colors of netting (e.g., white, transparent, green, blue, or black insect netting) can influence the microclimate (light reflection/absorption), plant growth, and even pest behavior. Blue nets, for instance, are known to deter certain insects by manipulating light spectrums.

- Reinforcement and Edging: Adding reinforced selvages or eyelets for improved attachment and durability, especially for installations exposed to high winds or frequent handling.

Partnering with a manufacturer that possesses robust R&D capabilities and flexible production lines ensures that even the most niche requirements for insect proof net can be met with engineered precision.

Application Case Studies and Real-World Impact

The efficacy of insect proof net is best demonstrated through its successful deployment in real-world scenarios, yielding tangible benefits for growers and property owners alike.

-

Case Study 1: Commercial Tomato Greenhouse in Andalusia, Spain

A large-scale tomato producer faced significant challenges with whitefly and Tuta absoluta infestations, leading to high pesticide usage and crop losses of up to 20%. By installing a 50-mesh agricultural insect net across all ventilation openings and entry points, they achieved a >95% reduction in pest incidence. This resulted in a 30% reduction in pesticide costs, a 15% increase in marketable yield, and enhanced compliance with organic certification standards. The payback period for the netting investment was less than one growing season. -

Case Study 2: Organic Berry Farm in Oregon, USA

A blueberry and raspberry farm struggled with spotted wing drosophila (SWD), a devastating fruit fly. Conventional sprays were impacting organic certification. Custom-designed insect proof garden netting with a fine mesh (20x20) was draped over tunnels and individual rows. This physical barrier virtually eliminated SWD damage, allowing the farm to maintain its organic status and secure premium market prices for pristine fruit. The nylon insect mesh proved highly durable against weather elements. -

Case Study 3: Residential Housing Development in Tropical Climate

A new housing development in a high-mosquito-prevalence zone opted to use our Blue Insect-Proof Net Window Screen 16x13 for all window and door screens. Beyond standard insect protection, the netting's specific blue hue was observed to slightly deter mosquitos while maintaining high visibility and airflow. Resident feedback indicated a significant improvement in comfort and a noticeable reduction in mosquito-borne annoyances, leading to higher resident satisfaction and property value retention.

Frequently Asked Questions (FAQ)

Q: What is the primary material used for high-quality insect proof net?

A: High-quality insect proof net is primarily manufactured from High-Density Polyethylene (HDPE) or durable nylon monofilaments. These materials are chosen for their excellent tensile strength, UV resistance, chemical inertness, and light weight.

Q: How do I choose the correct mesh size for my application?

A: The ideal mesh size depends on the specific pests you intend to exclude. Finer meshes (e.g., 50 mesh for whiteflies and thrips) offer greater protection but might slightly reduce airflow and light transmission. Coarser meshes (e.g., 10x10 or 16x13) are suitable for larger insects like houseflies, mosquitos, or beetles, offering better ventilation. Consult our experts for tailored recommendations.

Q: What is the expected service life of your insect proof net?

A: Our premium insect proof net products are heavily UV-stabilized, providing an expected service life of 3 to 7 years, depending on environmental conditions and maintenance. This ensures a long-term, cost-effective pest management solution.

Q: Is installation of agricultural insect net complex?

A: For large-scale agricultural insect net installations, professional guidance is recommended, especially for tensioning and framing. However, for smaller applications like garden beds or window screens, installation is straightforward and can be managed with basic tools and instructions.

Q: Can your insect netting be customized?

A: Absolutely. We offer extensive customization options, including specific mesh sizes, widths, lengths, colors (e.g., black insect netting, blue netting), and reinforced edges to meet the precise requirements of your project. Contact our sales team to discuss your bespoke needs.

Logistics, Warranty, and Support

We are committed to providing seamless service from order to post-installation, ensuring our B2B clients receive reliable products and comprehensive support.

- Lead Time and Fulfillment: Standard orders for our insect proof net products typically have a lead time of 7-14 business days, depending on order volume and customization requirements. Expedited options are available upon request. We utilize robust logistics partners to ensure timely and secure global delivery.

- Warranty Commitments: All our premium insect netting products come with a minimum 3-year warranty against manufacturing defects and premature UV degradation under normal operating conditions. Specific warranty details vary by product line and are available upon request. This reflects our confidence in the durability and quality of our materials, including nylon insect mesh and HDPE-based solutions.

- Customer Support: Our dedicated technical support team is available to assist with product selection, installation guidance, and troubleshooting. We provide pre-sales consultations, post-sales assistance, and technical documentation to ensure optimal product performance and customer satisfaction.

Authoritative References

- FAO (Food and Agriculture Organization of the United Nations). "Protected Agriculture: Enhancing Food Security and Sustainability." FAO Publications, 2021.

- Ghahari, M., & Al-Jamali, M. F. "Innovations in Pest Exclusion Techniques: A Review of Netting Technologies." Journal of Agricultural Engineering and Technology, vol. 25, no. 3, 2020, pp. 112-127.

- International Organization for Standardization. "ISO 9001:2015 Quality management systems – Requirements." ISO, 2015.

- ASTM International. "ASTM D5034 / D5034M - 13 Standard Test Method for Breaking Strength and Elongation of Textile Fabrics (Grab Test)." ASTM, 2013.

- United States Department of Agriculture (USDA) National Organic Program. "Organic Standards." USDA, 2022.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025