Premium Welded Wire Mesh: Durable, Versatile & Reliable Solutions

Introduction to Welded Wire Mesh: Trends and Strategic Importance

In critical infrastructure, industrial, and construction sectors, welded wire mesh stands as a foundational material, recognized for its exceptional strength, versatility, and durability. This engineered product, formed by precisely welding intersecting wires, offers superior structural integrity compared to woven alternatives, making it indispensable for applications ranging from concrete reinforcement and security fencing to sophisticated erosion control systems like gabion structures. Its consistent grid pattern and high weld strength contribute significantly to project longevity and safety.

The global demand for high-performance mesh solutions is driven by several key industry trends. Sustainability is paramount, prompting a shift towards materials with extended service life and recyclability, such as hot-dipped galvanized options that reduce maintenance and replacement cycles. Automation in manufacturing continues to advance, ensuring unparalleled precision in mesh fabrication and enabling the production of increasingly complex custom geometries. Furthermore, the integration of high-strength alloys and advanced coating technologies is expanding the operational envelope of welded wire mesh, allowing it to perform under more extreme environmental conditions. Digital transformation in supply chain management is also enhancing efficiency, offering better traceability and faster fulfillment for B2B clients globally.

These trends collectively underscore the evolving requirements for robust, reliable, and environmentally responsible materials, positioning welded wire mesh as a critical component in future-proof engineering and construction projects across diverse sectors.

The Advanced Manufacturing Process of Welded Wire Mesh

The production of welded wire mesh is a sophisticated industrial process, meticulously controlled to ensure superior quality, strength, and durability. This multi-stage process integrates advanced materials, precision engineering, and rigorous quality assurance protocols to meet stringent international standards.

1. Material Selection & Preparation

High-grade steel wire is chosen based on application requirements. Common materials include low-carbon steel (Q195, Q235 for general applications), galvanized steel (for enhanced corrosion resistance), and stainless steel (304, 316 for extreme environments). Wires undergo initial quality checks for tensile strength, elongation, and material composition via spectral analysis.

2. Wire Straightening & Cutting

Coiled wires are fed into automated straightening and cutting machines. These CNC-controlled systems ensure precise wire lengths and remove any inherent curvature, preparing them for the welding stage with minimal tolerance deviation. This critical step ensures uniform mesh aperture and panel dimensions.

3. Automated Resistance Welding

Longitudinal and transverse wires are precisely positioned and fused together using advanced resistance welding technology. Multi-point welding machines apply controlled current and pressure at each intersection, creating robust, uniform welds. This process, often automated, ensures consistent grid formation and high shear strength at every joint, crucial for the structural integrity of the mesh.

4. Surface Treatment (Galvanization/Coating)

For enhanced corrosion resistance, the welded mesh undergoes surface treatment. Hot-dipped galvanization (HDG) involves immersing the mesh in molten zinc, creating a metallurgically bonded, sacrificial coating. Alternatively, electro-galvanization or PVC coating (available in various colors for specific aesthetic or protective requirements) can be applied. HDG typically provides a service life exceeding 50 years in non-aggressive environments.

5. Quality Control & Testing

Post-production, each batch undergoes rigorous quality control. This includes dimensional accuracy checks (mesh opening, panel size), weld shear strength tests (e.g., to ASTM A740 standards), zinc coating thickness verification (for galvanized products), and visual inspection for defects. Adherence to standards such as ISO 9001, ASTM, EN, and ANSI/AWWA ensures product reliability and performance.

6. Finishing & Packaging

Finished mesh panels are trimmed, bundled, or rolled for shipping. Specialized packaging methods are employed to protect the product during transit, ensuring it arrives at the client's site in optimal condition. Each package is clearly labeled with product specifications and traceability information.

This meticulous process ensures that the resulting welded wire mesh exhibits high consistency, exceptional strength, and superior durability, making it ideal for demanding industrial and civil engineering applications where product integrity is paramount. For example, in water supply & drainage projects, the corrosion resistance and stable structure of HDG mesh ensure prolonged service life and reduced maintenance, offering significant energy saving through longevity and efficiency.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of welded wire mesh is crucial for its effective application in diverse B2B projects. Parameters such as wire diameter, mesh opening, material grade, and surface treatment directly influence the product's mechanical properties, durability, and suitability for specific structural or protective functions.

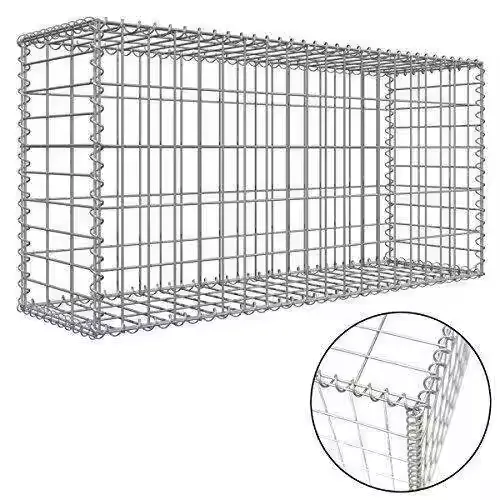

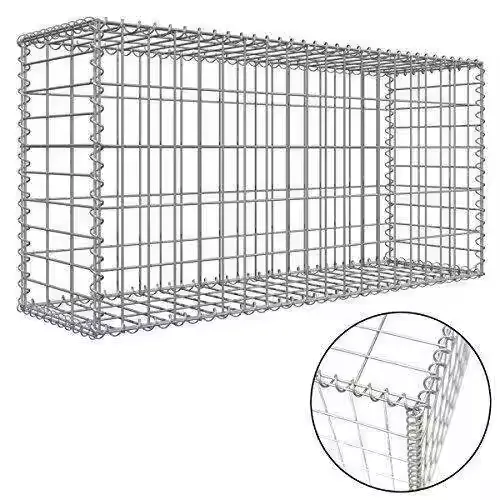

Product Specification: Welded Gabion Box 2x1x1 Hot Dipped Galvanized Welded Mesh Gabion

These specifications highlight the robust engineering behind products like the Welded Gabion Box. The heavy hot-dipped galvanization, for instance, provides a zinc coating thickness of at least 240 g/m², significantly extending the service life and maintaining structural integrity even in challenging environmental conditions, particularly critical for applications in infrastructure and water management.

Versatile Application Scenarios Across Key Industries

The adaptability and strength of welded wire mesh make it a preferred material across an extensive range of B2B applications and target industries. Its structural consistency and robust nature ensure reliability in demanding environments.

Primary Target Industries:

- ✓ Construction & Civil Engineering: Essential for concrete reinforcement, formwork, retaining walls, bridge abutments, and sound barriers, particularly with gabion structures.

- ✓ Water Supply & Drainage: Used in channel lining, river bank protection, weir construction, and erosion control, where permeability and resistance to water flow are critical.

- ✓ Mining & Geological Protection: Critical for rockfall protection, slope stabilization, tunnel linings, and safety barriers in harsh mining environments.

- ✓ Petrochemical & Industrial: Employed in security fencing for critical infrastructure, machine guards, storage partitions, and animal enclosures.

- ✓ Agriculture & Aquaculture: Widely used for livestock fencing, animal cages, and protective barriers.

Advantages in Typical Application Scenarios:

Gabion Retaining Walls & Erosion Control

- ✓ Flexibility & Permeability: Gabion structures, built with welded wire mesh, can adapt to ground movement without losing integrity, preventing hydrostatic pressure buildup behind walls. This natural drainage capability significantly contributes to their long-term stability and environmental integration.

- ✓ Corrosion Resistance: Hot-dipped galvanized mesh ensures exceptional resistance to rust, making gabions ideal for waterways, coastal protection, and areas prone to moisture, offering an impressive service life.

- ✓ Environmental Integration: Allows for vegetation growth within the rock fill, enhancing aesthetics and ecological value, promoting biodiversity and natural slope stabilization.

Concrete Reinforcement & Structural Support

- ✓ Enhanced Structural Integrity: The high tensile strength and uniform spacing of welded wire mesh reinforcement prevent concrete cracking and improve load-bearing capacity in slabs, foundations, and precast elements.

- ✓ Labor & Cost Efficiency: Pre-fabricated mesh panels reduce on-site cutting and tying, accelerating construction timelines and lowering labor costs, thereby contributing to overall project energy saving.

- ✓ Quality Consistency: Factory-welded mesh ensures precise spacing and optimal material utilization, minimizing variability and enhancing structural reliability compared to traditional rebar.

The robust engineering and design flexibility inherent in welded wire mesh allow for innovative solutions to complex challenges across these industries, providing long-term value and operational efficiencies.

Technical Advantages and Performance Excellence

The inherent technical advantages of welded wire mesh contribute significantly to its widespread adoption and superior performance in demanding applications. These advantages are rooted in its manufacturing precision, material science, and robust structural characteristics.

- ‣ High Strength-to-Weight Ratio: Engineered with optimal wire diameters and mesh spacings, welded wire mesh provides exceptional structural support while minimizing material usage. This efficient design translates into reduced dead loads for structures and optimized material costs without compromising performance. The precise welding technique ensures that the full tensile strength of the wire is largely maintained at the intersections, unlike some woven alternatives where wire movement can occur.

- ‣ Uniform Mesh and Consistent Welding: Advanced automated welding processes guarantee precise and consistent mesh apertures across entire panels. This uniformity is crucial for predictable structural performance, ensuring even distribution of stress and reliable reinforcement. The robotic welding systems employed in manufacturing adhere to strict parameters, resulting in superior weld shear strength that significantly surpasses minimum industry standards (e.g., typically exceeding 70% of the wire's ultimate tensile strength per ASTM A740).

- ‣ Excellent Corrosion Resistance: For applications in corrosive environments (e.g., marine, industrial chemical exposure, outdoor installations), hot-dipped galvanized (HDG) welded wire mesh offers unparalleled protection. The metallurgical bond between the zinc coating and steel substrate provides both barrier protection and cathodic (sacrificial) protection. This heavy galvanization, typically exceeding 240 g/m² zinc, ensures a service life often extending beyond 50 years, drastically reducing maintenance and replacement costs. PVC coating further enhances this resistance and offers aesthetic versatility.

- ‣ Versatility and Adaptability: The ability to customize wire diameters, mesh sizes, and panel dimensions allows welded wire mesh to be tailored to specific project needs. From ultra-fine mesh for filtration to heavy-gauge mesh for structural reinforcement, its adaptability makes it suitable for a vast array of applications, including complex geometries and architectural designs.

- ‣ Ease of Installation and Cost-Effectiveness: Pre-fabricated mesh panels significantly simplify on-site installation. This reduces labor requirements, accelerates project timelines, and minimizes errors compared to assembling individual wires or bars. The long-term durability and minimal maintenance needs of galvanized mesh translate into substantial life-cycle cost savings, contributing to overall project sustainability and energy conservation.

- ‣ Environmental Benefits: Welded wire mesh is often manufactured from recycled steel and is fully recyclable at the end of its long service life. Its durability and low maintenance requirements reduce waste and the environmental impact associated with frequent replacements, aligning with modern green building and sustainable infrastructure practices.

Vendor Comparison and Customized Solutions

Selecting the right supplier for welded wire mesh is a critical decision for B2B procurement, impacting project timelines, costs, and long-term performance. A thorough vendor comparison, coupled with robust customization capabilities, ensures optimal outcomes.

Key Criteria for Vendor Comparison:

Tailored Customization Solutions:

Meeting the unique demands of modern infrastructure and industrial projects often requires more than off-the-shelf solutions. Leading manufacturers offer comprehensive customization options for welded wire mesh, ensuring precise fit and optimal performance.

- ● Specific Dimensions: Custom wire diameters (e.g., from 2.0mm to 8.0mm), mesh openings (e.g., 25x25mm to 200x200mm), and panel sizes to perfectly match project requirements, minimizing waste and simplifying installation.

- ● Material Versatility: Beyond standard low-carbon steel, options include stainless steel grades (304, 316 for enhanced chemical resistance), high-tensile steel, or specialty alloys for unique performance needs.

- ● Specialized Surface Treatments: In addition to HDG, customized PVC coatings in various RAL colors for aesthetic integration or specific environmental protection (e.g., UV resistance, chemical splash zones), or specialized epoxy coatings.

- ● Fabrication & Forming: Pre-bending, cutting to specific shapes, or integrating additional components to deliver ready-to-install modules, reducing on-site fabrication.

- ● Engineering Support: Collaboration with client engineers to optimize designs, perform structural analysis, and ensure compliance with project-specific regulatory requirements.

Application Case Studies and Client Experience

Real-world application case studies demonstrate the tangible benefits and proven reliability of welded wire mesh in complex B2B projects. Our extensive experience, spanning over 20 years in the industry, has allowed us to partner with numerous reputable clients on critical infrastructure and industrial developments.

Case Study 1: Highway Embankment Stabilization with Welded Gabion Boxes

- ✓ Challenge: A major highway expansion project in a mountainous region required robust slope stabilization for newly constructed embankments prone to erosion and geological instability. Traditional concrete retaining walls were deemed too rigid and costly, with significant environmental impact.

- ✓ Solution: We supplied customized hot-dipped galvanized welded wire mesh gabion boxes (2x1x1m, 4.0mm wire, 75x75mm mesh) for constructing multi-tiered retaining walls. The permeability of the gabions allowed for natural drainage, alleviating hydrostatic pressure, while their inherent flexibility accommodated minor ground movements.

- ✓ Results: The gabion walls provided superior long-term stability and erosion control for over 5 km of highway embankment. The ease of assembly and availability of pre-fabricated units significantly reduced installation time by 30% compared to conventional methods. The natural rock infill promoted revegetation, enhancing the aesthetic appeal and ecological value of the landscape. Our project management and technical support ensured seamless integration with the client's engineering team, contributing to on-time and on-budget completion.

Case Study 2: Industrial Facility Security Fencing in a Coastal Environment

- ✓ Challenge: A petrochemical facility located near a coastal area required high-security perimeter fencing that could withstand harsh saline conditions and strong winds, while deterring unauthorized access. Durability and minimal maintenance were key considerations.

- ✓ Solution: We provided heavy-duty welded wire mesh panels with a thick hot-dipped galvanized coating and an additional marine-grade PVC coating. The mesh design incorporated small apertures (50x50mm) to prevent climbing and cutting, combined with robust wire diameters (5.0mm) for maximum rigidity. Custom-fabricated panel sizes and secure mounting systems were developed to meet the specific site security requirements.

- ✓ Results: The fencing system successfully established a highly secure perimeter, effectively deterring intrusions. The dual-layer corrosion protection ensured the fence remained intact and free from degradation despite continuous exposure to sea spray and strong UV radiation, significantly reducing the need for costly maintenance. The client reported enhanced security operations and a notable improvement in asset protection, citing the superior material quality and expert installation guidance as critical success factors.

“Our collaboration on the highway embankment project was seamless. The durability and ease of assembly of their welded wire mesh gabions exceeded our expectations, delivering a robust and visually appealing solution that integrated perfectly with the environment. Their technical team provided invaluable support throughout the project lifecycle.”

Trustworthiness & Comprehensive Support

Establishing trust in the B2B sector is paramount. We achieve this through transparent processes, robust commitments, and unwavering customer support. Our dedication to client satisfaction extends beyond product delivery to encompass every stage of the project lifecycle.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of Hot-Dipped Galvanized welded wire mesh?

A: Hot-dipped galvanized (HDG) welded wire mesh typically offers an impressive service life of 50 to 70 years in most atmospheric environments, and even longer in less aggressive conditions. This longevity is attributed to the thick, metallurgically bonded zinc coating (often exceeding 240 g/m²) which provides both barrier and cathodic protection against corrosion.

Q2: Can your products be customized for specific project requirements?

A: Absolutely. We specialize in customized solutions. We can tailor wire diameters, mesh openings, panel dimensions, material grades (e.g., stainless steel), and various surface treatments (e.g., specific RAL colors for PVC coating) to meet the precise technical and aesthetic requirements of your project. Our engineering team collaborates closely with clients to develop optimal custom designs.

Q3: What testing standards do your welded wire mesh products meet?

A: Our products are manufactured and tested in strict adherence to leading international standards, including ISO 9001 for quality management, ASTM A740/A740M for welded wire fabric, EN 10223-4 for steel wire mesh fencing, and relevant ANSI/AWWA standards for water infrastructure applications. We provide comprehensive test reports and certifications upon request.

Q4: How does welded wire mesh contribute to environmental sustainability?

A: Welded wire mesh contributes to sustainability through several aspects: its long service life (especially HDG options) reduces the need for frequent replacement; it is often produced from recycled steel and is fully recyclable at the end of its use; and in applications like gabions, it promotes natural drainage and supports ecological restoration by allowing vegetation growth.

Lead Time & Fulfillment

We understand the critical nature of project schedules. Our standard lead times for typical orders range from 2-4 weeks, depending on product complexity and volume. For large-scale or highly customized projects, we work closely with clients to establish realistic and efficient production and delivery schedules. Our robust logistics network ensures reliable and timely global shipping, with dedicated support for customs and documentation.

Warranty Commitments

All our welded wire mesh products come with a comprehensive warranty against manufacturing defects and material failures under normal use. Specific warranty periods vary by product type and application, typically ranging from 5 to 10 years for material and workmanship. For galvanized products, the longevity of the corrosion protection system is guaranteed in accordance with relevant international standards. Full warranty details are provided with every quotation.

Customer Support & After-Sales Service

Our commitment extends well beyond the point of sale. We offer dedicated customer support, including technical assistance from our team of engineers for installation guidance, application troubleshooting, and product optimization. Our after-sales service team is readily available to address any inquiries, facilitate replacements, or provide further support, ensuring continuous operational excellence for your projects. We maintain open communication channels, including phone, email, and dedicated online portals for efficient issue resolution.

Conclusion

The robust engineering, versatile applications, and superior performance characteristics of welded wire mesh position it as an indispensable material in modern B2B industries. From enhancing the structural integrity of concrete to providing long-lasting erosion control solutions with gabions, its technical advantages deliver tangible value. With a commitment to quality, customization, and comprehensive client support, manufacturers of high-grade welded wire mesh continue to drive innovation and provide reliable solutions for the evolving demands of global infrastructure and industrial projects.

Authoritative References

- ASTM International. (n.d.). ASTM A740/A740M-16: Standard Specification for Hardware Cloth (Welded Wire Fabric).

- International Organization for Standardization. (n.d.). ISO 9001: Quality Management Systems – Requirements.

- Galvanizers Association. (n.d.). The Corrosion Protection of Hot Dip Galvanized Coatings.

- American Society of Civil Engineers. (n.d.). Geotechnical Engineering Journal.

- British Standards Institution. (n.d.). EN 10223-4: Steel wire and wire products for fences and netting - Part 4: Steel wire welded mesh for fencing.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025

Premium Welded Wire Mesh: Durable, Versatile & Reliable Solutions

Introduction to Welded Wire Mesh: Trends and Strategic Importance

In critical infrastructure, industrial, and construction sectors, welded wire mesh stands as a foundational material, recognized for its exceptional strength, versatility, and durability. This engineered product, formed by precisely welding intersecting wires, offers superior structural integrity compared to woven alternatives, making it indispensable for applications ranging from concrete reinforcement and security fencing to sophisticated erosion control systems like gabion structures. Its consistent grid pattern and high weld strength contribute significantly to project longevity and safety.

The global demand for high-performance mesh solutions is driven by several key industry trends. Sustainability is paramount, prompting a shift towards materials with extended service life and recyclability, such as hot-dipped galvanized options that reduce maintenance and replacement cycles. Automation in manufacturing continues to advance, ensuring unparalleled precision in mesh fabrication and enabling the production of increasingly complex custom geometries. Furthermore, the integration of high-strength alloys and advanced coating technologies is expanding the operational envelope of welded wire mesh, allowing it to perform under more extreme environmental conditions. Digital transformation in supply chain management is also enhancing efficiency, offering better traceability and faster fulfillment for B2B clients globally.

These trends collectively underscore the evolving requirements for robust, reliable, and environmentally responsible materials, positioning welded wire mesh as a critical component in future-proof engineering and construction projects across diverse sectors.

The Advanced Manufacturing Process of Welded Wire Mesh

The production of welded wire mesh is a sophisticated industrial process, meticulously controlled to ensure superior quality, strength, and durability. This multi-stage process integrates advanced materials, precision engineering, and rigorous quality assurance protocols to meet stringent international standards.

1. Material Selection & Preparation

High-grade steel wire is chosen based on application requirements. Common materials include low-carbon steel (Q195, Q235 for general applications), galvanized steel (for enhanced corrosion resistance), and stainless steel (304, 316 for extreme environments). Wires undergo initial quality checks for tensile strength, elongation, and material composition via spectral analysis.

2. Wire Straightening & Cutting

Coiled wires are fed into automated straightening and cutting machines. These CNC-controlled systems ensure precise wire lengths and remove any inherent curvature, preparing them for the welding stage with minimal tolerance deviation. This critical step ensures uniform mesh aperture and panel dimensions.

3. Automated Resistance Welding

Longitudinal and transverse wires are precisely positioned and fused together using advanced resistance welding technology. Multi-point welding machines apply controlled current and pressure at each intersection, creating robust, uniform welds. This process, often automated, ensures consistent grid formation and high shear strength at every joint, crucial for the structural integrity of the mesh.

4. Surface Treatment (Galvanization/Coating)

For enhanced corrosion resistance, the welded mesh undergoes surface treatment. Hot-dipped galvanization (HDG) involves immersing the mesh in molten zinc, creating a metallurgically bonded, sacrificial coating. Alternatively, electro-galvanization or PVC coating (available in various colors for specific aesthetic or protective requirements) can be applied. HDG typically provides a service life exceeding 50 years in non-aggressive environments.

5. Quality Control & Testing

Post-production, each batch undergoes rigorous quality control. This includes dimensional accuracy checks (mesh opening, panel size), weld shear strength tests (e.g., to ASTM A740 standards), zinc coating thickness verification (for galvanized products), and visual inspection for defects. Adherence to standards such as ISO 9001, ASTM, EN, and ANSI/AWWA ensures product reliability and performance.

6. Finishing & Packaging

Finished mesh panels are trimmed, bundled, or rolled for shipping. Specialized packaging methods are employed to protect the product during transit, ensuring it arrives at the client's site in optimal condition. Each package is clearly labeled with product specifications and traceability information.

This meticulous process ensures that the resulting welded wire mesh exhibits high consistency, exceptional strength, and superior durability, making it ideal for demanding industrial and civil engineering applications where product integrity is paramount. For example, in water supply & drainage projects, the corrosion resistance and stable structure of HDG mesh ensure prolonged service life and reduced maintenance, offering significant energy saving through longevity and efficiency.

Technical Specifications and Performance Parameters

Understanding the precise technical specifications of welded wire mesh is crucial for its effective application in diverse B2B projects. Parameters such as wire diameter, mesh opening, material grade, and surface treatment directly influence the product's mechanical properties, durability, and suitability for specific structural or protective functions.

Product Specification: Welded Gabion Box 2x1x1 Hot Dipped Galvanized Welded Mesh Gabion

These specifications highlight the robust engineering behind products like the Welded Gabion Box. The heavy hot-dipped galvanization, for instance, provides a zinc coating thickness of at least 240 g/m², significantly extending the service life and maintaining structural integrity even in challenging environmental conditions, particularly critical for applications in infrastructure and water management.

Versatile Application Scenarios Across Key Industries

The adaptability and strength of welded wire mesh make it a preferred material across an extensive range of B2B applications and target industries. Its structural consistency and robust nature ensure reliability in demanding environments.

Primary Target Industries:

- ✓ Construction & Civil Engineering: Essential for concrete reinforcement, formwork, retaining walls, bridge abutments, and sound barriers, particularly with gabion structures.

- ✓ Water Supply & Drainage: Used in channel lining, river bank protection, weir construction, and erosion control, where permeability and resistance to water flow are critical.

- ✓ Mining & Geological Protection: Critical for rockfall protection, slope stabilization, tunnel linings, and safety barriers in harsh mining environments.

- ✓ Petrochemical & Industrial: Employed in security fencing for critical infrastructure, machine guards, storage partitions, and animal enclosures.

- ✓ Agriculture & Aquaculture: Widely used for livestock fencing, animal cages, and protective barriers.

Advantages in Typical Application Scenarios:

Gabion Retaining Walls & Erosion Control

- ✓ Flexibility & Permeability: Gabion structures, built with welded wire mesh, can adapt to ground movement without losing integrity, preventing hydrostatic pressure buildup behind walls. This natural drainage capability significantly contributes to their long-term stability and environmental integration.

- ✓ Corrosion Resistance: Hot-dipped galvanized mesh ensures exceptional resistance to rust, making gabions ideal for waterways, coastal protection, and areas prone to moisture, offering an impressive service life.

- ✓ Environmental Integration: Allows for vegetation growth within the rock fill, enhancing aesthetics and ecological value, promoting biodiversity and natural slope stabilization.

Concrete Reinforcement & Structural Support

- ✓ Enhanced Structural Integrity: The high tensile strength and uniform spacing of welded wire mesh reinforcement prevent concrete cracking and improve load-bearing capacity in slabs, foundations, and precast elements.

- ✓ Labor & Cost Efficiency: Pre-fabricated mesh panels reduce on-site cutting and tying, accelerating construction timelines and lowering labor costs, thereby contributing to overall project energy saving.

- ✓ Quality Consistency: Factory-welded mesh ensures precise spacing and optimal material utilization, minimizing variability and enhancing structural reliability compared to traditional rebar.

The robust engineering and design flexibility inherent in welded wire mesh allow for innovative solutions to complex challenges across these industries, providing long-term value and operational efficiencies.

Technical Advantages and Performance Excellence

The inherent technical advantages of welded wire mesh contribute significantly to its widespread adoption and superior performance in demanding applications. These advantages are rooted in its manufacturing precision, material science, and robust structural characteristics.

- ‣ High Strength-to-Weight Ratio: Engineered with optimal wire diameters and mesh spacings, welded wire mesh provides exceptional structural support while minimizing material usage. This efficient design translates into reduced dead loads for structures and optimized material costs without compromising performance. The precise welding technique ensures that the full tensile strength of the wire is largely maintained at the intersections, unlike some woven alternatives where wire movement can occur.

- ‣ Uniform Mesh and Consistent Welding: Advanced automated welding processes guarantee precise and consistent mesh apertures across entire panels. This uniformity is crucial for predictable structural performance, ensuring even distribution of stress and reliable reinforcement. The robotic welding systems employed in manufacturing adhere to strict parameters, resulting in superior weld shear strength that significantly surpasses minimum industry standards (e.g., typically exceeding 70% of the wire's ultimate tensile strength per ASTM A740).

- ‣ Excellent Corrosion Resistance: For applications in corrosive environments (e.g., marine, industrial chemical exposure, outdoor installations), hot-dipped galvanized (HDG) welded wire mesh offers unparalleled protection. The metallurgical bond between the zinc coating and steel substrate provides both barrier protection and cathodic (sacrificial) protection. This heavy galvanization, typically exceeding 240 g/m² zinc, ensures a service life often extending beyond 50 years, drastically reducing maintenance and replacement costs. PVC coating further enhances this resistance and offers aesthetic versatility.

- ‣ Versatility and Adaptability: The ability to customize wire diameters, mesh sizes, and panel dimensions allows welded wire mesh to be tailored to specific project needs. From ultra-fine mesh for filtration to heavy-gauge mesh for structural reinforcement, its adaptability makes it suitable for a vast array of applications, including complex geometries and architectural designs.

- ‣ Ease of Installation and Cost-Effectiveness: Pre-fabricated mesh panels significantly simplify on-site installation. This reduces labor requirements, accelerates project timelines, and minimizes errors compared to assembling individual wires or bars. The long-term durability and minimal maintenance needs of galvanized mesh translate into substantial life-cycle cost savings, contributing to overall project sustainability and energy conservation.

- ‣ Environmental Benefits: Welded wire mesh is often manufactured from recycled steel and is fully recyclable at the end of its long service life. Its durability and low maintenance requirements reduce waste and the environmental impact associated with frequent replacements, aligning with modern green building and sustainable infrastructure practices.

Vendor Comparison and Customized Solutions

Selecting the right supplier for welded wire mesh is a critical decision for B2B procurement, impacting project timelines, costs, and long-term performance. A thorough vendor comparison, coupled with robust customization capabilities, ensures optimal outcomes.

Key Criteria for Vendor Comparison:

Tailored Customization Solutions:

Meeting the unique demands of modern infrastructure and industrial projects often requires more than off-the-shelf solutions. Leading manufacturers offer comprehensive customization options for welded wire mesh, ensuring precise fit and optimal performance.

- ● Specific Dimensions: Custom wire diameters (e.g., from 2.0mm to 8.0mm), mesh openings (e.g., 25x25mm to 200x200mm), and panel sizes to perfectly match project requirements, minimizing waste and simplifying installation.

- ● Material Versatility: Beyond standard low-carbon steel, options include stainless steel grades (304, 316 for enhanced chemical resistance), high-tensile steel, or specialty alloys for unique performance needs.

- ● Specialized Surface Treatments: In addition to HDG, customized PVC coatings in various RAL colors for aesthetic integration or specific environmental protection (e.g., UV resistance, chemical splash zones), or specialized epoxy coatings.

- ● Fabrication & Forming: Pre-bending, cutting to specific shapes, or integrating additional components to deliver ready-to-install modules, reducing on-site fabrication.

- ● Engineering Support: Collaboration with client engineers to optimize designs, perform structural analysis, and ensure compliance with project-specific regulatory requirements.

Application Case Studies and Client Experience

Real-world application case studies demonstrate the tangible benefits and proven reliability of welded wire mesh in complex B2B projects. Our extensive experience, spanning over 20 years in the industry, has allowed us to partner with numerous reputable clients on critical infrastructure and industrial developments.

Case Study 1: Highway Embankment Stabilization with Welded Gabion Boxes

- ✓ Challenge: A major highway expansion project in a mountainous region required robust slope stabilization for newly constructed embankments prone to erosion and geological instability. Traditional concrete retaining walls were deemed too rigid and costly, with significant environmental impact.

- ✓ Solution: We supplied customized hot-dipped galvanized welded wire mesh gabion boxes (2x1x1m, 4.0mm wire, 75x75mm mesh) for constructing multi-tiered retaining walls. The permeability of the gabions allowed for natural drainage, alleviating hydrostatic pressure, while their inherent flexibility accommodated minor ground movements.

- ✓ Results: The gabion walls provided superior long-term stability and erosion control for over 5 km of highway embankment. The ease of assembly and availability of pre-fabricated units significantly reduced installation time by 30% compared to conventional methods. The natural rock infill promoted revegetation, enhancing the aesthetic appeal and ecological value of the landscape. Our project management and technical support ensured seamless integration with the client's engineering team, contributing to on-time and on-budget completion.

Case Study 2: Industrial Facility Security Fencing in a Coastal Environment

- ✓ Challenge: A petrochemical facility located near a coastal area required high-security perimeter fencing that could withstand harsh saline conditions and strong winds, while deterring unauthorized access. Durability and minimal maintenance were key considerations.

- ✓ Solution: We provided heavy-duty welded wire mesh panels with a thick hot-dipped galvanized coating and an additional marine-grade PVC coating. The mesh design incorporated small apertures (50x50mm) to prevent climbing and cutting, combined with robust wire diameters (5.0mm) for maximum rigidity. Custom-fabricated panel sizes and secure mounting systems were developed to meet the specific site security requirements.

- ✓ Results: The fencing system successfully established a highly secure perimeter, effectively deterring intrusions. The dual-layer corrosion protection ensured the fence remained intact and free from degradation despite continuous exposure to sea spray and strong UV radiation, significantly reducing the need for costly maintenance. The client reported enhanced security operations and a notable improvement in asset protection, citing the superior material quality and expert installation guidance as critical success factors.

“Our collaboration on the highway embankment project was seamless. The durability and ease of assembly of their welded wire mesh gabions exceeded our expectations, delivering a robust and visually appealing solution that integrated perfectly with the environment. Their technical team provided invaluable support throughout the project lifecycle.”

Trustworthiness & Comprehensive Support

Establishing trust in the B2B sector is paramount. We achieve this through transparent processes, robust commitments, and unwavering customer support. Our dedication to client satisfaction extends beyond product delivery to encompass every stage of the project lifecycle.

Frequently Asked Questions (FAQ)

Q1: What is the typical lifespan of Hot-Dipped Galvanized welded wire mesh?

A: Hot-dipped galvanized (HDG) welded wire mesh typically offers an impressive service life of 50 to 70 years in most atmospheric environments, and even longer in less aggressive conditions. This longevity is attributed to the thick, metallurgically bonded zinc coating (often exceeding 240 g/m²) which provides both barrier and cathodic protection against corrosion.

Q2: Can your products be customized for specific project requirements?

A: Absolutely. We specialize in customized solutions. We can tailor wire diameters, mesh openings, panel dimensions, material grades (e.g., stainless steel), and various surface treatments (e.g., specific RAL colors for PVC coating) to meet the precise technical and aesthetic requirements of your project. Our engineering team collaborates closely with clients to develop optimal custom designs.

Q3: What testing standards do your welded wire mesh products meet?

A: Our products are manufactured and tested in strict adherence to leading international standards, including ISO 9001 for quality management, ASTM A740/A740M for welded wire fabric, EN 10223-4 for steel wire mesh fencing, and relevant ANSI/AWWA standards for water infrastructure applications. We provide comprehensive test reports and certifications upon request.

Q4: How does welded wire mesh contribute to environmental sustainability?

A: Welded wire mesh contributes to sustainability through several aspects: its long service life (especially HDG options) reduces the need for frequent replacement; it is often produced from recycled steel and is fully recyclable at the end of its use; and in applications like gabions, it promotes natural drainage and supports ecological restoration by allowing vegetation growth.

Lead Time & Fulfillment

We understand the critical nature of project schedules. Our standard lead times for typical orders range from 2-4 weeks, depending on product complexity and volume. For large-scale or highly customized projects, we work closely with clients to establish realistic and efficient production and delivery schedules. Our robust logistics network ensures reliable and timely global shipping, with dedicated support for customs and documentation.

Warranty Commitments

All our welded wire mesh products come with a comprehensive warranty against manufacturing defects and material failures under normal use. Specific warranty periods vary by product type and application, typically ranging from 5 to 10 years for material and workmanship. For galvanized products, the longevity of the corrosion protection system is guaranteed in accordance with relevant international standards. Full warranty details are provided with every quotation.

Customer Support & After-Sales Service

Our commitment extends well beyond the point of sale. We offer dedicated customer support, including technical assistance from our team of engineers for installation guidance, application troubleshooting, and product optimization. Our after-sales service team is readily available to address any inquiries, facilitate replacements, or provide further support, ensuring continuous operational excellence for your projects. We maintain open communication channels, including phone, email, and dedicated online portals for efficient issue resolution.

Conclusion

The robust engineering, versatile applications, and superior performance characteristics of welded wire mesh position it as an indispensable material in modern B2B industries. From enhancing the structural integrity of concrete to providing long-lasting erosion control solutions with gabions, its technical advantages deliver tangible value. With a commitment to quality, customization, and comprehensive client support, manufacturers of high-grade welded wire mesh continue to drive innovation and provide reliable solutions for the evolving demands of global infrastructure and industrial projects.

Authoritative References

- ASTM International. (n.d.). ASTM A740/A740M-16: Standard Specification for Hardware Cloth (Welded Wire Fabric).

- International Organization for Standardization. (n.d.). ISO 9001: Quality Management Systems – Requirements.

- Galvanizers Association. (n.d.). The Corrosion Protection of Hot Dip Galvanized Coatings.

- American Society of Civil Engineers. (n.d.). Geotechnical Engineering Journal.

- British Standards Institution. (n.d.). EN 10223-4: Steel wire and wire products for fences and netting - Part 4: Steel wire welded mesh for fencing.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025