Premium Welded Wire Mesh | Durable 3x3 Fencing & Security

The Foundation of Modern Infrastructure: Understanding Welded Wire

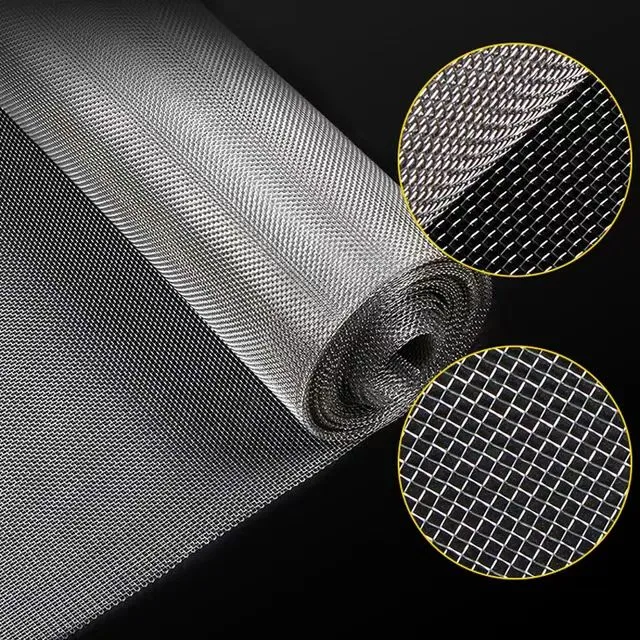

In the diverse landscape of B2B industrial materials, welded wire stands out as a fundamental component, crucial for numerous applications requiring structural integrity, security, and filtration. This versatile material, formed by precisely welding intersecting wires, offers unparalleled strength and uniformity, making it an indispensable choice for engineers, contractors, and manufacturers across the globe. From reinforcing concrete structures to crafting robust security barriers and intricate filtration systems, its widespread adoption underscores its technical superiority and cost-effectiveness. The market for welded wire continues to expand, driven by global infrastructure development, increasing demand for reliable security solutions, and advancements in material science that enhance its performance parameters.

Industry trends indicate a significant shift towards more sustainable and high-performance materials. Manufacturers are focusing on producing welded wire with enhanced corrosion resistance, higher tensile strength, and greater customization capabilities to meet the evolving demands of complex industrial projects. The integration of automation and advanced quality control systems in the manufacturing process further ensures consistency and adherence to stringent international standards, solidifying welded wire's position as a premium industrial product.

Precision Engineering: The Manufacturing Process of Welded Wire

The production of high-quality welded wire mesh involves a meticulous multi-stage process designed to ensure material integrity, precise dimensions, and superior performance. This intricate journey transforms raw wire rod into a robust, finished product capable of meeting demanding industrial specifications.

1. Wire Rod Selection and Drawing

- Material Specification: The process begins with selecting high-grade wire rod, typically low-carbon steel (e.g., SAE 1008, 1010) for general applications or stainless steel (e.g., 304, 316) for enhanced corrosion resistance. The choice depends entirely on the intended application and environmental conditions.

- Wire Drawing: The selected wire rod is then cold drawn through a series of dies, gradually reducing its diameter to the desired gauge. This process not only achieves the specific wire thickness but also significantly increases the wire's tensile strength and improves its surface finish, making it ideal for subsequent welding.

2. Straightening and Cutting

Once drawn, the wires are fed into straightening machines to eliminate any residual curvature from the coiling process. Precision cutting machines then trim the wires to exact lengths, preparing them for the welding stage. This step is critical for ensuring the uniformity and precise mesh openings of the final product.

3. Automated Electric Resistance Welding

- Cross-Wire Alignment: Longitudinal and transverse wires are accurately positioned to form the specified mesh pattern (e.g., a perfect 3x3 wire mesh configuration). Advanced computer numerical control (CNC) systems ensure exceptional precision in wire spacing.

- Fusion Welding: At each intersection, an electric current is passed through the wires under pressure, generating localized heat that fuses the wires together without the need for filler material. This electric resistance welding technique creates a strong, durable, and permanent bond that is crucial for the structural integrity of the mesh.

4. Surface Treatment

-

Galvanization: For enhanced corrosion resistance, the mesh can undergo galvanization.

- Electro-Galvanization (Cold Plating): A thin, uniform layer of zinc is applied electrolytically. This process offers a bright, smooth finish and good rust protection for indoor or less aggressive outdoor environments.

- Hot-Dip Galvanization: The mesh is immersed in molten zinc, creating a thicker, more durable coating that provides superior protection against harsh environmental conditions, making it ideal for exterior applications like welding fence wire.

- PVC Coating: For additional protection, aesthetics, and specific functional requirements (e.g., UV resistance, color coding), a layer of PVC can be applied over the galvanized mesh.

5. Quality Control and Packaging

Throughout the entire manufacturing process, rigorous testing standards are applied. This includes dimensional checks, weld strength tests, material composition analysis, and coating thickness measurements, adhering to international standards such as ISO 9001 for quality management and specific product standards like ASTM A185/A82 for concrete reinforcement. The final product is then carefully inspected, rolled or cut into sheets, and packaged for safe transport and delivery. The service life of galvanized welded wire can extend beyond 15-20 years in typical atmospheric conditions, while PVC coated versions can last even longer.

Technical Specifications and Parameters for Optimal Performance

Understanding the technical specifications of welded wire is paramount for selecting the appropriate product for any given application. These parameters dictate the mesh's structural integrity, durability, and suitability for various environmental and load-bearing conditions. Key specifications include material composition, wire diameter, mesh opening, tensile strength, yield strength, and surface treatment details.

Material Composition

Typically, low-carbon steel (Q195, Q235) is used for its excellent weldability and cost-effectiveness. For applications requiring superior corrosion resistance or chemical stability, stainless steel (e.g., SUS304, SUS316) is preferred. The specific steel grade determines the material's inherent strength, ductility, and resistance to environmental degradation.

Wire Diameter and Mesh Opening

Wire diameter, often measured in millimeters or gauges, directly correlates with the mesh's overall strength and rigidity. Mesh opening refers to the distance between the centers of adjacent parallel wires, expressed as dimensions like 25x25mm (1x1 inch) or 75x75mm (3x3 wire mesh). A common configuration like 3x3 inch (75x75mm) mesh with a 4.0mm (8 gauge) wire is robust enough for many industrial fencing and concrete reinforcement tasks.

Mechanical Properties

- Tensile Strength: The maximum stress the wire can withstand while being stretched or pulled before breaking. For low-carbon steel welded wire, typical tensile strengths range from 450-700 MPa (Megapascals).

- Yield Strength: The stress at which the wire begins to deform plastically. This is a critical parameter for structural applications, often around 300-500 MPa for standard industrial grades.

- Elongation: A measure of the wire's ductility, indicating how much it can stretch before fracturing. Typical values are 8-15%.

Surface Treatment Properties

For galvanized mesh, the zinc coating thickness is crucial for corrosion resistance. Electro-galvanized coatings typically range from 10-30 g/m², while hot-dip galvanized coatings offer significantly thicker layers, often 50-300 g/m² per side, providing superior longevity in aggressive environments. PVC coatings add an additional layer of protection, typically 0.5-1.5mm thick, offering UV stability and chemical resistance.

Typical Welded Wire Mesh Specifications

Versatile Applications and Technical Advantages

The inherent strength, uniformity, and adaptability of welded wire make it a cornerstone material across a multitude of industries. Its technical advantages translate directly into long-term cost savings, enhanced safety, and improved operational efficiency for B2B clients.

Target Industries and Application Scenarios

- Construction and Infrastructure: Widely used for concrete reinforcement in slabs, roads, foundations, and precast elements. It significantly improves tensile strength, preventing cracking and extending structural lifespan. For example, in large-scale building projects, the consistent grid provided by welded wire mesh ensures uniform stress distribution, critical for seismic resilience.

- Security and Fencing: As welding fence wire, it forms robust barriers for industrial sites, public spaces, and agricultural enclosures. The strong, fixed joints prevent unraveling, offering superior intruder deterrence compared to woven mesh. PVC-coated variants are popular for aesthetic appeal and enhanced corrosion resistance in residential and commercial fencing.

- Agricultural and Horticultural: Utilized for animal enclosures, trellises, crop protection, and greenhouse benches. A 3x3 wire mesh offers adequate spacing for many animal types while providing robust containment.

- Industrial and Manufacturing: Employed in machine guards, shelving units, storage cages, and various filtration applications. Its rigidity and open structure make it ideal for protecting machinery while allowing ventilation and visibility.

- Water Supply & Drainage: Used in gabions for erosion control, retaining walls, and in filtration systems for municipal water treatment or industrial wastewater management.

- Petrochemical: Stainless steel welded wire mesh finds application in high-temperature or corrosive environments for support structures, catalysts beds, and safety barriers, demonstrating exceptional resistance to chemical degradation.

- Metallurgy: Used for screening, conveying, and safety enclosures in mining and metal processing plants where durability and resistance to abrasion are crucial.

Key Technical Advantages

- Superior Strength and Rigidity: The precisely welded intersections create a rigid, stable structure that resists deformation under stress, offering higher strength-to-weight ratios compared to traditional materials. This translates to energy saving in terms of reduced material consumption for structural support.

- Dimensional Stability: Fixed wire spacing ensures consistent mesh openings, critical for applications requiring precise filtration or uniform structural support.

- Corrosion Resistance: Galvanized and PVC-coated options provide excellent protection against rust, chemicals, and environmental elements, significantly extending service life and reducing maintenance costs.

- Ease of Fabrication and Installation: Welded wire mesh can be easily cut, bent, and formed without unraveling, simplifying installation and reducing labor costs on site. Its flat, uniform surface facilitates quicker placement in concrete applications.

- Versatility: Available in a vast array of wire diameters, mesh sizes, materials, and finishes, allowing for tailor-made solutions for specific project requirements.

Customized Welded Wire Solutions for Specific Project Needs

Recognizing that no two industrial projects are exactly alike, leading manufacturers offer extensive customization options for welded wire mesh. This flexibility ensures that clients receive products precisely tailored to their unique functional, environmental, and aesthetic requirements, optimizing performance and cost-efficiency.

Tailoring Dimensions and Configurations

- Wire Diameter: Customizable from fine gauges (e.g., 0.4mm) for precise filtration to heavy gauges (e.g., 6.0mm) for demanding structural support or robust welding fence wire applications.

- Mesh Opening: The size and shape of the mesh openings can be customized, ranging from small, tight meshes (e.g., 6x6mm) for pest control or fine filtration to larger, more open patterns (e.g., 100x100mm) for heavy-duty fencing or general reinforcement. Common options like 3x3 wire mesh are often the starting point, but bespoke sizes are readily available.

- Panel Size: Production in custom panel dimensions (width and length) minimizes waste and speeds up installation, whether for large construction sites or specific product components.

- Roll Length: For applications requiring continuous material, custom roll lengths are offered to streamline deployment and reduce seams.

Material and Coating Options

- Base Material: Choice between various grades of low-carbon steel for standard applications or stainless steel (304, 316, 316L) for environments demanding superior corrosion resistance, high temperatures, or chemical inertness.

- Surface Treatment: Options include electro-galvanizing for a bright, smooth finish; hot-dip galvanizing for maximum corrosion protection in outdoor or harsh environments; and PVC coating in a variety of colors for enhanced durability, UV resistance, and aesthetic integration.

Fabrication and Finishing Services

Beyond basic mesh production, many suppliers offer value-added fabrication services, including custom cutting, bending, and forming to create ready-to-install components. This can include precise cuts for machinery guards, complex bends for architectural elements, or pre-formed sections for gabion baskets. These customized solutions not only ensure perfect fit and function but also significantly reduce on-site labor and material wastage, leading to more efficient project completion and overall cost savings.

Vendor Comparison and Selection Criteria for Welded Wire Mesh

Choosing the right supplier for welded wire mesh is a critical decision that impacts project quality, budget, and timeline. B2B decision-makers must evaluate vendors based on a comprehensive set of criteria beyond just price, focusing on quality, reliability, and service.

Key Evaluation Criteria

- Quality and Certifications: Look for vendors with ISO 9001 certification and adherence to relevant ASTM or regional standards (e.g., CE marking for European markets). This indicates a commitment to consistent manufacturing processes and product quality.

- Experience and Reputation: A long-standing history of successful projects and positive client testimonials speaks volumes about a vendor's expertise and reliability. Partners like large construction firms or government agencies are strong indicators of trust.

- Customization Capabilities: The ability to provide bespoke solutions in terms of wire gauge, mesh size (3x3 wire mesh, etc.), material type, and surface finish is crucial for specialized projects.

- Lead Time and Logistics: Timely delivery is essential for project schedules. Assess a vendor's production capacity, inventory management, and shipping efficiency.

- Technical Support and After-Sales Service: The availability of technical guidance, design assistance, and responsive customer support for any post-purchase issues.

- Pricing and Value: While not the sole factor, a competitive pricing structure coupled with high-quality products and services offers the best value proposition. Transparent pricing without hidden costs is a significant advantage.

Vendor Comparison Table Example

Real-World Application Case Studies and Client Success

The practical utility and robust performance of welded wire are best demonstrated through its successful deployment in diverse, real-world scenarios. These case studies highlight how tailored solutions contribute to project efficiency, longevity, and security.

Case Study 1: Large-Scale Commercial Property Fencing

A major logistics hub required a robust and visually appealing perimeter security solution for its sprawling campus. Traditional chain-link fencing lacked the rigidity and aesthetic appeal desired. Our solution involved supplying hot-dip galvanized welding fence wire panels with a 50x50mm mesh and 4.0mm wire diameter. The panels were designed for quick installation, and the consistent weld strength ensured high security against potential breaches. The client reported a 30% reduction in installation time compared to previous projects using alternative materials, and significantly enhanced visual deterrence. The robust galvanization also promised decades of maintenance-free operation, resisting the corrosive elements prevalent in industrial areas.

— Project Manager, Global Logistics Corporation

Case Study 2: Agricultural Animal Enclosures

A large-scale poultry farm needed durable and hygienic enclosure materials for new brooding houses. The primary requirements were easy cleaning, resistance to animal gnawing, and longevity in a moisture-rich environment. We provided custom-sized electro-galvanized 3x3 wire mesh panels with 2.5mm wire, which offered ideal ventilation and waste drainage. The smooth, cold-plated surface made cleaning effortless, and the fixed welds prevented the mesh from being distorted by the animals. The farm has been using our mesh for over five years with no signs of degradation, contributing to better animal welfare and operational efficiency.

— Operations Director, Agro-Industrial Group

Case Study 3: Concrete Reinforcement for Industrial Flooring

For a new heavy machinery manufacturing plant, the concrete flooring needed exceptional load-bearing capacity and crack resistance. Our specialized steel welded wire reinforcement mesh, conforming to ASTM A185 standards, was specified. The mesh panels were supplied in large sheets, reducing the number of overlaps and ensuring faster, more accurate placement. The high yield strength of the wire and the consistent weld integrity significantly enhanced the concrete's ability to withstand dynamic loads from heavy equipment and continuous traffic. Post-installation evaluations confirmed superior crack control and structural integrity, exceeding client expectations.

— Lead Engineer, Industrial Construction Firm

Ensuring Trustworthiness: FAQs, Lead Times, Warranty, and Support

For B2B clients, trustworthiness extends beyond product quality to encompass transparent processes, reliable delivery, and robust after-sales support. We are committed to fostering long-term partnerships through clear communication and comprehensive service.

Frequently Asked Questions (FAQ)

- Q: What is the typical lead time for custom welded wire orders?

- A: Standard orders typically have a lead time of 1-2 weeks. For highly customized or very large volume orders, lead times can range from 3-5 weeks, depending on complexity and current production schedules. We always provide a precise timeline at the quotation stage.

- Q: What warranty do you offer on your welded wire mesh products?

- A: Our products come with a comprehensive warranty against manufacturing defects. Electro-galvanized products typically carry a 5-year warranty, while hot-dip galvanized and PVC-coated options can extend up to 10 years, reflecting their superior durability and corrosion resistance. Specific terms are detailed in our sales agreements.

- Q: Can you provide certification for material conformity and testing standards?

- A: Absolutely. All our products are manufactured under ISO 9001 certified processes. We provide Material Test Reports (MTRs) and Certificates of Conformance (CoC) for every shipment, detailing material composition, mechanical properties, and adherence to relevant international standards like ASTM A185/A82, ASTM A641, and local building codes as required.

- Q: How do you handle large volume orders or ongoing supply contracts?

- A: We have robust production capabilities and an efficient logistics network to handle large-scale projects and establish long-term supply agreements. Dedicated account managers work closely with clients to forecast demand, manage inventory, and ensure just-in-time delivery to optimize their supply chain.

Lead Time and Fulfillment

Our streamlined production processes and strategic inventory management allow for competitive lead times. For most standard orders of common mesh sizes and finishes (e.g., electro-galvanized welded wire panels), we aim for fulfillment within 7-14 business days. Custom orders or high-volume requirements are meticulously planned with our clients to establish realistic and achievable delivery schedules, often leveraging partial shipments to keep projects on track.

Warranty Commitments

We stand by the quality of our Professional Factory Iron Wire Mesh Cold Plated Electric Welding Mesh. Our warranty covers manufacturing defects and material integrity for a specified period, ensuring peace of mind for our clients. The exact duration varies based on product type and surface treatment, with galvanized and PVC-coated products offering extended warranty periods due to their enhanced durability. Detailed warranty information is provided with every quotation and invoice.

Dedicated Customer Support

Our commitment to our clients extends far beyond the sale. We provide comprehensive customer support, including pre-sales technical consultation, assistance with material selection, and post-sales service. Our team of experts is available to answer questions, resolve issues, and provide technical guidance, ensuring optimal product performance and customer satisfaction. You can reach us via phone, email, or through our dedicated online portal, ensuring a prompt and professional response.

Conclusion

The selection of high-quality welded wire is a strategic decision that underpins the success and longevity of countless B2B projects. Its versatility, combined with advancements in manufacturing and surface treatment, positions it as an indispensable material for industries ranging from construction and agriculture to security and heavy manufacturing. By prioritizing precision in production, adherence to stringent international standards, and offering extensive customization options, we provide solutions that not only meet but exceed the demanding performance requirements of modern industrial applications. Investing in superior welded wire mesh ensures structural integrity, enhanced security, prolonged service life, and ultimately, greater value for your projects.

References

- American Society for Testing and Materials (ASTM) International. ASTM A185/A185M - 17a, Standard Specification for Steel Welded Wire Reinforcement, Plain, for Concrete. ASTM International, West Conshohocken, PA, 2017.

- International Organization for Standardization (ISO). ISO 9001:2015, Quality management systems — Requirements. ISO, Geneva, Switzerland, 2015.

- The Galvanizers Association. "Corrosion Protection by Hot Dip Galvanizing." Retrieved from www.galvanizing.org.uk.

- Wire Reinforcement Institute (WRI). "Welded Wire Reinforcement: Design, Specifications, and Applications." Retrieved from www.wirereinforcementinstitute.org.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025