-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 26, 2025 01:20

Back to list

Welded Gabion Box 2x1x1 Hot Dipped Galvanized Welded Mesh Gabion

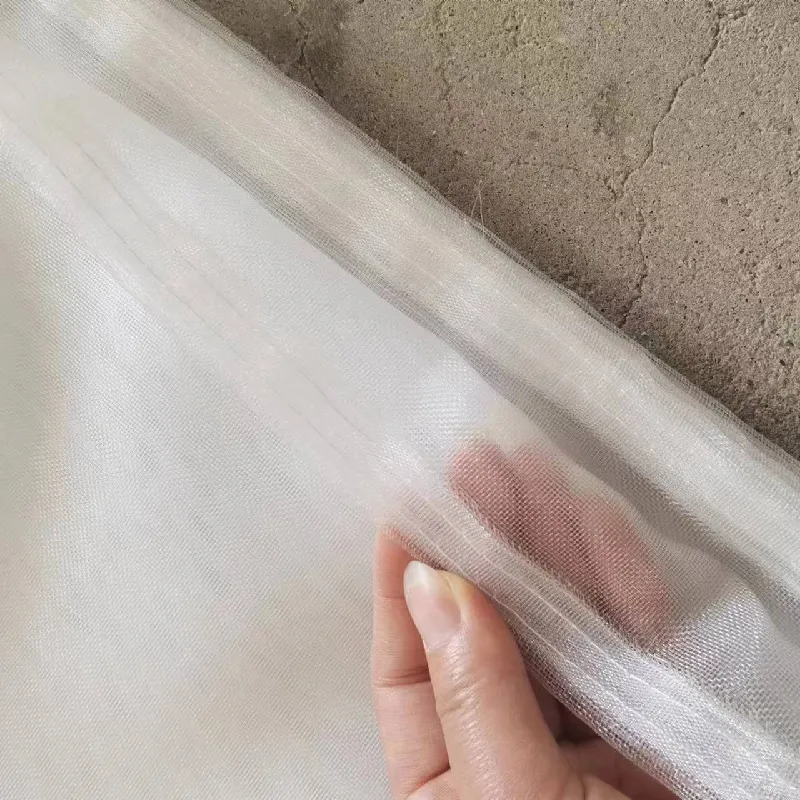

In the intricate world of construction and manufacturing, PVC coated wire mesh emerges as an essential component, marrying durability with versatility. Across various industries, its applications are both critical and diverse. Understanding the realm of PVC coated wire mesh manufacturers can help businesses and individuals make informed decisions that align with their specific needs.

Safety and environmental responsibility stand at the forefront of manufacturing priority. As industry leaders, manufacturers emphasize the importance of non-toxic and environmentally safe PVC coatings. Adopting eco-friendly practices not only reduces harmful emissions during production but also ensures that the wire mesh products are safe for applications involving wildlife and plant life, making them suitable for use in protected areas and agricultural settings. Trustworthiness in this industry is often built on transparent customer interactions and comprehensive after-sales support. Manufacturers emphasize building long-term relationships through dedicated customer service teams that guide consumers in selecting, installing, and maintaining their wire mesh. By offering technical support and practical advice, these manufacturers ensure their products deliver peak performance throughout their lifecycle. The authority of a PVC coated wire mesh manufacturer doesn't solely rest on product quality but also extends to industry contribution. Through partnerships with research institutions and participation in industry forums, these manufacturers push the boundaries of application and efficiency. They invest in research and development to continuously innovate, enhancing the capabilities and applications of wire mesh products to meet future demands. In choosing a manufacturer, considerations should extend beyond the immediate purchase to evaluating their overall contribution to the field, as well as their commitment to quality and customer satisfaction. The most esteemed manufacturers are those that view every transaction as an opportunity to advance their craft, fortify their reputation, and contribute positively to their industry. Ultimately, the decision to partner with a PVC coated wire mesh manufacturer should be informed by their cumulative experience, technical expertise, and unwavering dedication to quality assurance. By aligning with market leaders who prioritize these attributes, businesses can guarantee that they are investing in products that will meet rigorous demands and contribute positively to their project's success and safety.

Safety and environmental responsibility stand at the forefront of manufacturing priority. As industry leaders, manufacturers emphasize the importance of non-toxic and environmentally safe PVC coatings. Adopting eco-friendly practices not only reduces harmful emissions during production but also ensures that the wire mesh products are safe for applications involving wildlife and plant life, making them suitable for use in protected areas and agricultural settings. Trustworthiness in this industry is often built on transparent customer interactions and comprehensive after-sales support. Manufacturers emphasize building long-term relationships through dedicated customer service teams that guide consumers in selecting, installing, and maintaining their wire mesh. By offering technical support and practical advice, these manufacturers ensure their products deliver peak performance throughout their lifecycle. The authority of a PVC coated wire mesh manufacturer doesn't solely rest on product quality but also extends to industry contribution. Through partnerships with research institutions and participation in industry forums, these manufacturers push the boundaries of application and efficiency. They invest in research and development to continuously innovate, enhancing the capabilities and applications of wire mesh products to meet future demands. In choosing a manufacturer, considerations should extend beyond the immediate purchase to evaluating their overall contribution to the field, as well as their commitment to quality and customer satisfaction. The most esteemed manufacturers are those that view every transaction as an opportunity to advance their craft, fortify their reputation, and contribute positively to their industry. Ultimately, the decision to partner with a PVC coated wire mesh manufacturer should be informed by their cumulative experience, technical expertise, and unwavering dedication to quality assurance. By aligning with market leaders who prioritize these attributes, businesses can guarantee that they are investing in products that will meet rigorous demands and contribute positively to their project's success and safety.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025