-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

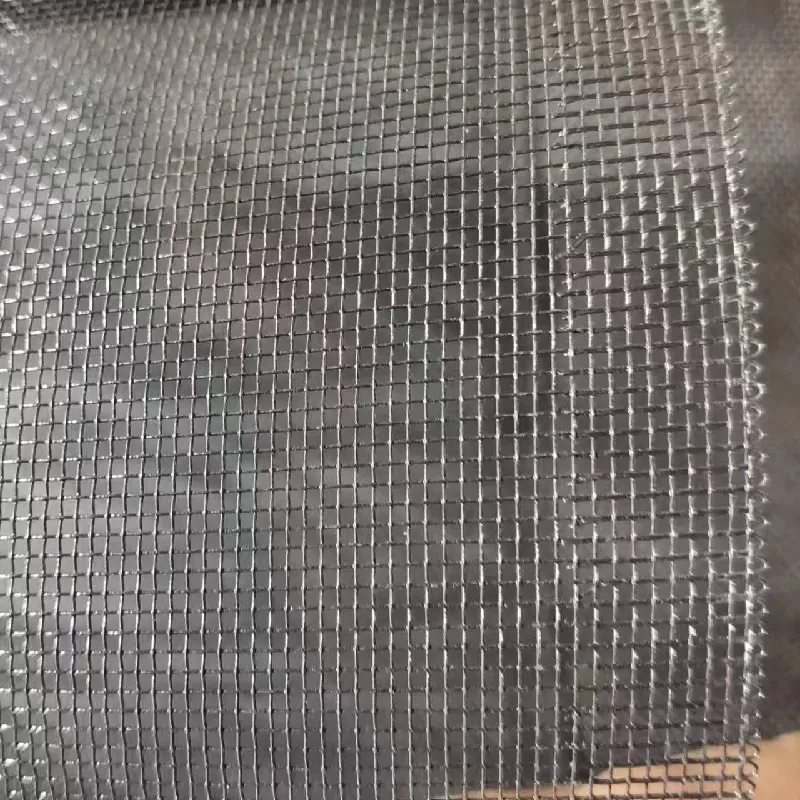

rack netting

The Concept and Importance of Rack Netting in Modern Warehousing

In today's fast-paced commercial environment, efficient inventory management is critical for businesses aiming to optimize their operations. One of the innovative solutions that have gained popularity in warehouses and distribution centers is rack netting. This system involves the use of netting suspended from racking systems to secure items, ensuring their safety and enhancing organizational efficiency.

Rack netting serves multiple purposes, with the primary goal being to prevent products from falling off shelves or racking systems. This is particularly important in environments where high racks store various goods, from small parts to larger items. The use of netting creates a physical barrier that contains products, protecting them from damage and reducing the risk of injury to warehouse personnel.

The implementation of rack netting brings forth several benefits. Firstly, it enhances safety in the workplace. In warehouses, falling objects can pose serious hazards, not only to the inventory itself but also to employees who navigate the aisles. The netting acts as a safeguard that prevents items from tumbling down during the picking process or due to vibration and movement within the warehouse. This measure significantly reduces workplace accidents and contributes to a safer working environment.

Secondly, rack netting contributes to improved inventory management. By containing products within the racks, warehouse operators can maximize the use of vertical space without the fear of product spills. This results in better organization and easier accessibility of items, which can streamline picking operations. Well-organized inventory facilitates quicker order fulfillment, allowing businesses to maintain a competitive edge in fast-tracked supply chains.

rack netting

Additionally, rack netting helps maintain product integrity. In many industries, particularly in food and pharmaceuticals, maintaining the quality and safety of products is paramount. The netting can support products such as boxes or containers, protecting them from external contamination and physical damage. This is especially crucial in sectors where even minor damage can lead to significant financial losses and harm to consumer trust.

Another factor to consider is compliance with regulations. Various industries are subject to stringent guidelines regarding product safety and workplace safety. By integrating rack netting into their operations, businesses can demonstrate a commitment to safety standards and regulatory compliance. This not only protects the company from potential legal repercussions but also enhances its reputation in the market.

The versatility of rack netting systems is also noteworthy. They can be customized to fit different types of racking and shelving systems, making them adaptable to a wide range of warehouse layouts and product types. Whether it is for a cold storage facility that requires temperature control or a traditional warehouse setting, rack netting can be tailored to meet specific logistical needs.

Furthermore, the installation of rack netting can be a cost-effective solution. Compared to extensive renovations of existing systems or the purchase of expensive safety barriers, netting is relatively affordable and straightforward to install. This ease of integration allows businesses to upgrade their safety protocols without significant financial burden.

In conclusion, rack netting presents a multifaceted solution for modern warehousing challenges. From enhancing safety and improving inventory management to maintaining product integrity and ensuring regulatory compliance, the benefits of incorporating netting systems are significant. As businesses continue to evolve and face increasingly complex logistical demands, the role of innovations such as rack netting will become even more critical in achieving operational efficiency and safety in the warehousing sector. Embracing this adaptable solution enables companies to not only safeguard their assets but also optimize their overall workflow, thus positioning themselves effectively within the competitive market landscape. As the demand for efficient warehouse operations grows, integrating rack netting could emerge as a standard practice for businesses aiming for excellence in inventory management.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025