-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

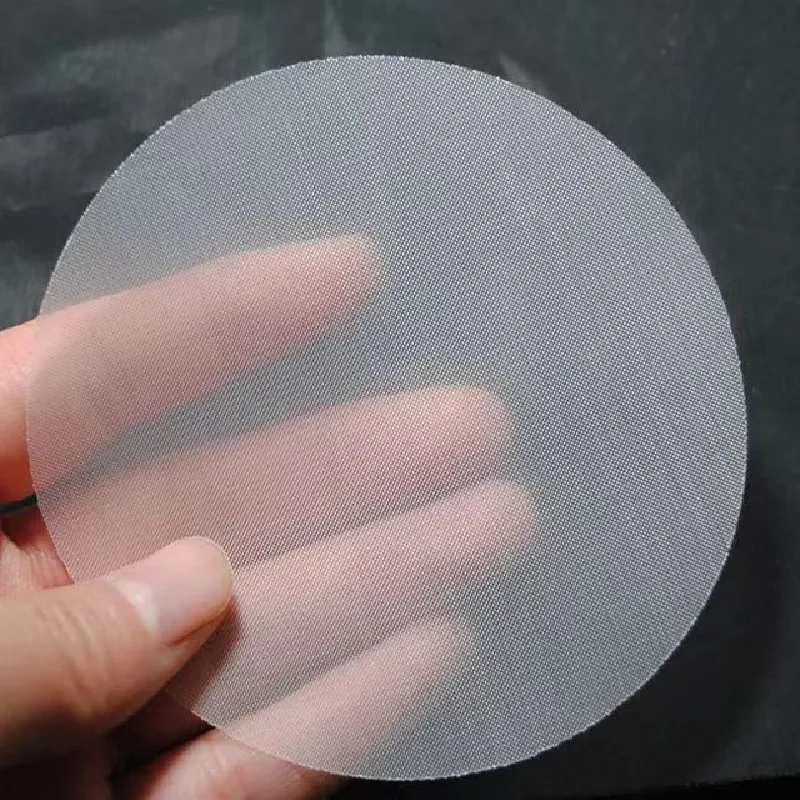

ref 245 mesh

Understanding Ref 245 Mesh A Comprehensive Overview

In the realm of materials science and engineering, the term mesh has become increasingly significant, particularly in applications involving filtration, structural reinforcement, and various composite materials. The reference to “Ref 245 Mesh” implies a specific standard or type of mesh, often used in various industrial and technological processes. This article will delve into the intricacies of mesh materials, their applications, and the importance of adhering to standards like Ref 245 Mesh in ensuring quality and performance.

What is Mesh?

Mesh is defined as a network of interlocking strands or wires, typically arranged in a grid-like pattern. This structure allows for specific properties such as porosity, flexibility, and strength. Mesh materials can be made from various types of substances, including metals, plastics, and textiles. Their versatility makes them invaluable in numerous sectors, ranging from construction to filtration and textiles.

The Importance of Mesh Standards

Standards are crucial in the manufacturing and application of mesh materials. They ensure consistency, quality, and safety across products. Ref 245 Mesh refers to a specific mesh standard that outlines the required specifications, dimensions, and performance characteristics for specific applications. Compliance with such standards guarantees that the mesh product will perform reliably and safely under its intended conditions.

Applications of Ref 245 Mesh

1. Filtration Systems

One of the primary applications of mesh is in filtration systems. Whether in water treatment, industrial processes, or air quality control, effective filtration is essential. Mesh that meets Ref 245 standards ensures that the openings are of the correct size and that the material has the appropriate strength to withstand the operational conditions. This is critical to maintain both the efficiency of the filtration process and the longevity of the filtering medium.

2. Construction and Civil Engineering

ref 245 mesh

In construction, mesh is often used for reinforcement, particularly in concrete structures. Rebar mesh, conforming to specific standards like Ref 245 Mesh, is critical for providing the necessary tensile strength to concrete, which is inherently weak under tension. Properly graded mesh not only enhances structural integrity but also contributes to the safety and durability of buildings and infrastructure.

3. Textiles and Clothing

Mesh fabrics are widely utilized in the textile industry, particularly for sportswear and breathable clothing. Mesh that adheres to specific industry standards ensures that the fabric retains its shape, breathability, and durability – critical factors for performance in activewear. The guidelines provided by standards like Ref 245 Mesh help manufacturers achieve consistent quality across their product lines.

4. Automotive and Aerospace Engineering

In the fields of automotive and aerospace engineering, mesh materials play a vital role in component manufacturing. Mesh can be used in areas requiring lightweight structures that do not compromise strength, such as in composite materials for vehicles or aircraft. Adhering to standards such as Ref 245 Mesh ensures that these components will meet rigorous safety and performance requirements.

The Future of Mesh Technology

As industries continue to evolve, so too will the applications and technologies surrounding mesh materials. With advancements in nanotechnology and materials science, future mesh products may incorporate additional properties, such as enhanced chemical resistance or self-cleaning capabilities. The establishment of new standards, alongside existing ones like Ref 245 Mesh, will play a significant role in ensuring that these innovations are safe and effective for their intended uses.

Conclusion

The significance of Ref 245 Mesh cannot be overstated. Whether in filtration, construction, textiles, or advanced engineering, the reliance on standardized mesh products ensures safety, efficiency, and consistent performance. As industries innovate and new standards arise, understanding and adhering to these specifications will be essential for manufacturers and consumers alike. The importance of mesh, therefore, extends beyond its physical properties; it symbolizes a commitment to quality, safety, and progress in technology and engineering.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025