-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

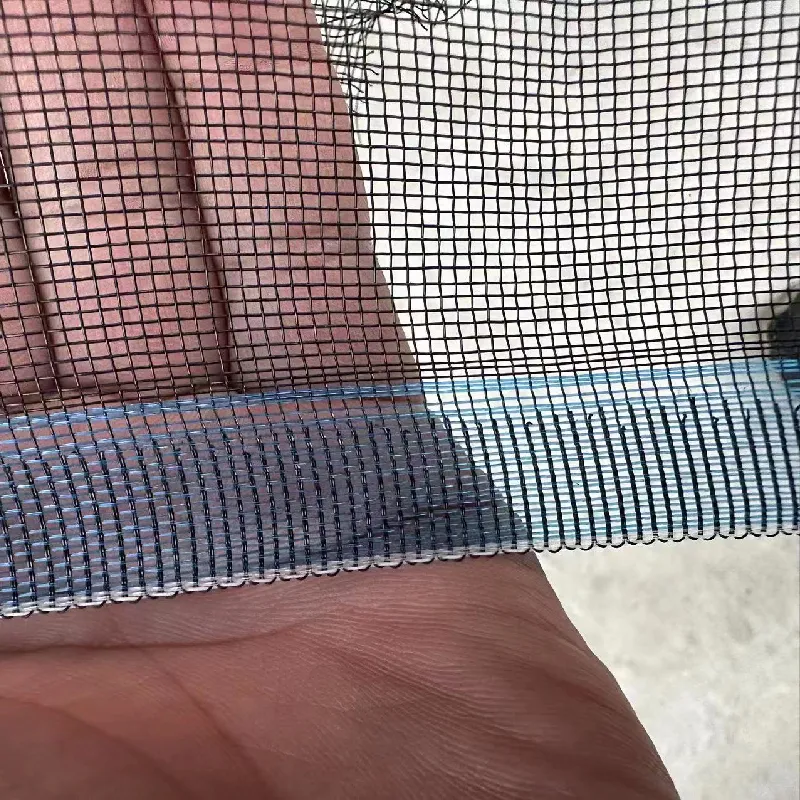

rigid plastic mesh

The Versatility and Applications of Rigid Plastic Mesh

In various industries, the material composition of products plays a pivotal role in determining their functionality and longevity. Among these materials, rigid plastic mesh has emerged as a remarkable choice due to its numerous practical benefits. This innovative material, characterized by its intricate network of rigid plastic strands, offers a unique combination of flexibility and strength, making it suitable for a wide array of applications.

Composition and Structure

Rigid plastic mesh is typically crafted from high-density polyethylene (HDPE), polypropylene (PP), or other durable plastics. The manufacturing process involves extruding the plastic into thin strands, which are then woven or arranged in a grid-like pattern. This structure not only provides strength and rigidity but also allows for lightweight and easy handling. The open spaces within the mesh enable air and liquids to pass through, which is essential for many specific applications.

Benefits of Rigid Plastic Mesh

One of the key advantages of rigid plastic mesh is its resistance to environmental factors. The material is inherently resistant to water, chemicals, and UV radiation, making it ideal for outdoor use. Unlike traditional materials such as wood or metal, rigid plastic mesh does not corrode or degrade over time, significantly extending its lifespan. Additionally, its lightweight nature allows for easy installation and flexibility in application.

Furthermore, the mesh can be customized in various dimensions, colors, and patterns to suit specific needs. This versatility makes it appealing in sectors ranging from agriculture to construction and even in everyday items like storage solutions and gardening accessories.

Applications Across Industries

rigid plastic mesh

The applications of rigid plastic mesh are extensive. In agriculture, it serves as a supportive framework for climbing plants, ensuring they grow upright while optimizing light exposure and air circulation. Farmers utilize rigid plastic mesh for trellises, plant supports, and even as protective barriers against pests. Its durability ensures that it withstands the rigors of outdoor farming conditions.

In construction and landscaping, rigid plastic mesh is used for erosion control and soil stabilization. It provides excellent drainage while preventing soil erosion, making it an invaluable tool for slope management. Additionally, it acts as a protective barrier in sports fields and parks, providing a safe environment for athletes and visitors alike.

Rigid plastic mesh is also prevalent in manufacturing and industrial applications. The mesh can be found in conveyor belts, where its strength and buoyancy allow it to carry materials efficiently within factories. It is utilized in storage solutions, such as bins and containers, due to its lightweight nature and structural integrity.

Moreover, in the realm of safety and security, rigid plastic mesh is employed in fencing applications. Whether it’s for residential properties or commercial installations, the mesh provides a robust barrier that is both visually appealing and functionally secure. It is resistant to tampering and can be easily installed in various settings.

Environmental Considerations

As sustainability becomes an increasingly important consideration in manufacturing, rigid plastic mesh stands out due to its recyclability. Many manufacturers are now producing rigid plastic mesh from recycled materials, further reducing the environmental impact. This focus on sustainability is vital as industries strive to adopt greener practices and minimize waste.

Conclusion

In conclusion, rigid plastic mesh is a multifaceted material that holds significant advantages across numerous industries. Its unique composition, combined with its durability and versatility, makes it an ideal choice for various applications, from agriculture to construction and beyond. As we continue to innovate and explore the potential of rigid plastic mesh, its importance is likely to grow, ensuring that it remains a crucial component in solving modern challenges. Whether utilized in everyday products or specialized industrial solutions, rigid plastic mesh stands as a testament to the ingenuity of modern materials science.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025