-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

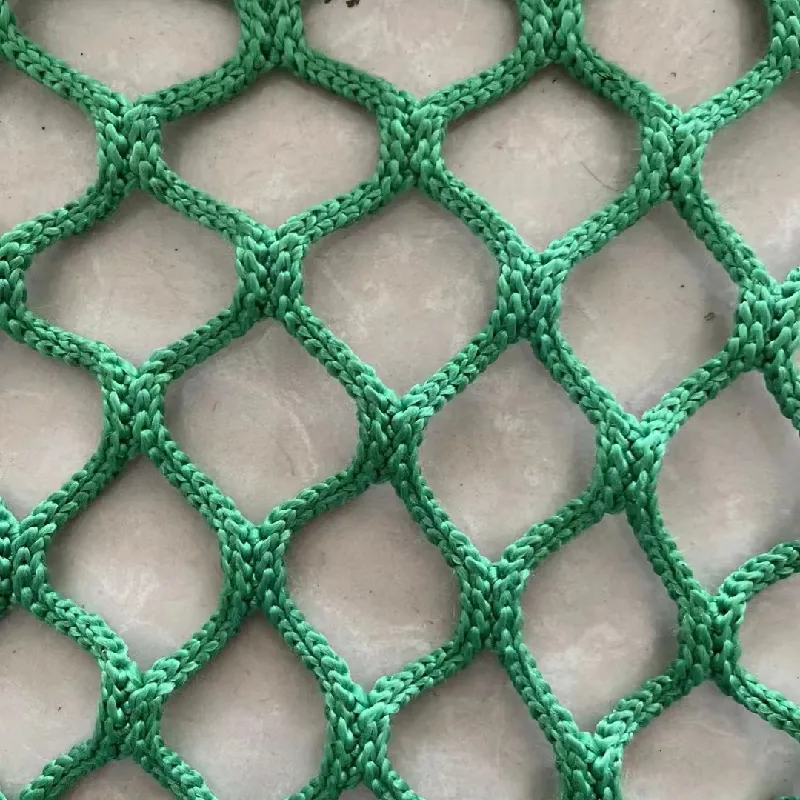

rubber coated metal mesh

The Versatility of Rubber Coated Metal Mesh

In today’s industrial world, the quest for materials that combine strength, flexibility, and durability is paramount. One such innovative material that has gained traction in various applications is the rubber coated metal mesh. This composite material not only brings the strength of metal but also the resilience and versatility of rubber, making it ideal for a myriad of uses across industries.

Understanding Rubber Coated Metal Mesh

Rubber coated metal mesh consists of a metal mesh framework that is coated with rubber. This unique combination leverages the benefits of both components the metal provides structural integrity, while the rubber enhances the mesh's flexibility and resistance to wear and tear. Typically, the metal used in this composite could be stainless steel, aluminum, or other alloys, chosen for their strength and resistance to corrosion. The rubber coating is often made of synthetic materials that can endure extreme temperatures and harsh environmental conditions.

Applications Across Industries

1. Construction and Architecture One of the primary applications of rubber coated metal mesh is in construction. It can be used in various structural components, including reinforcement for walls and ceilings, safety barriers, and decorative elements. Its strength ensures it can support heavy loads, while its rubber coating reduces the risk of injury from sharp metal edges.

2. Automotive Industry In the automotive sector, rubber coated metal mesh is widely utilized for grill covers, heat shields, and other components where durability and resistance to the elements are essential. The rubber coating acts as a barrier against rust and corrosion, extending the lifespan of the parts while also providing improved aesthetics.

3. Industrial Applications The industrial sector benefits immensely from rubber coated metal mesh in filtering systems, conveyor belts, and protective screens. The mesh's ability to withstand high pressure and the rubber’s shock-absorbing properties make it ideal for environments such as factories and processing plants where heavy machinery operates.

rubber coated metal mesh

4. Agriculture Farmers and agricultural engineers utilize rubber coated metal mesh for fencing, animal enclosures, and equipment covers. The material's resilience against environmental factors like moisture, UV rays, and extreme temperatures makes it an excellent choice for outdoor applications. Furthermore, the rubber coating minimizes wear on animals, reducing the risk of injury from the fencing materials.

5. Interior Design In the realm of interior design, rubber coated metal mesh finds its way into furniture, lighting fixtures, and decorative elements. Its aesthetic appeal combined with functionality allows designers to create unique pieces that can withstand daily use while enhancing the overall aesthetic of a space.

Benefits of Rubber Coated Metal Mesh

The advantages of rubber coated metal mesh are myriad. Firstly, it offers significant resistance to corrosion and rust, which is particularly important in applications exposed to moisture and harsh chemicals. Secondly, the rubber coating provides an element of flexibility, ensuring that the mesh can withstand substantial stress without deforming. Additionally, the cushioning effect of rubber prevents damage to both the mesh itself and adjacent surfaces, making it a protective solution in many contexts.

Moreover, the combination of metal and rubber is relatively lightweight compared to other materials with similar strength properties. This makes rubber coated metal mesh not only easier to handle and install but also beneficial in applications where weight restrictions are crucial.

Conclusion

In summary, rubber coated metal mesh stands out as a multifaceted material that brings together the best of both metal and rubber. Its applications span various industries including construction, automotive, and agriculture, offering solutions that are both practical and innovative. As industries continue to evolve and demands for durable, flexible materials grow, rubber coated metal mesh is poised to play an increasingly important role in shaping the future of material science and engineering. Whether for utilitarian use or aesthetic projects, this versatile material proves that functionality and design can go hand in hand.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025