-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

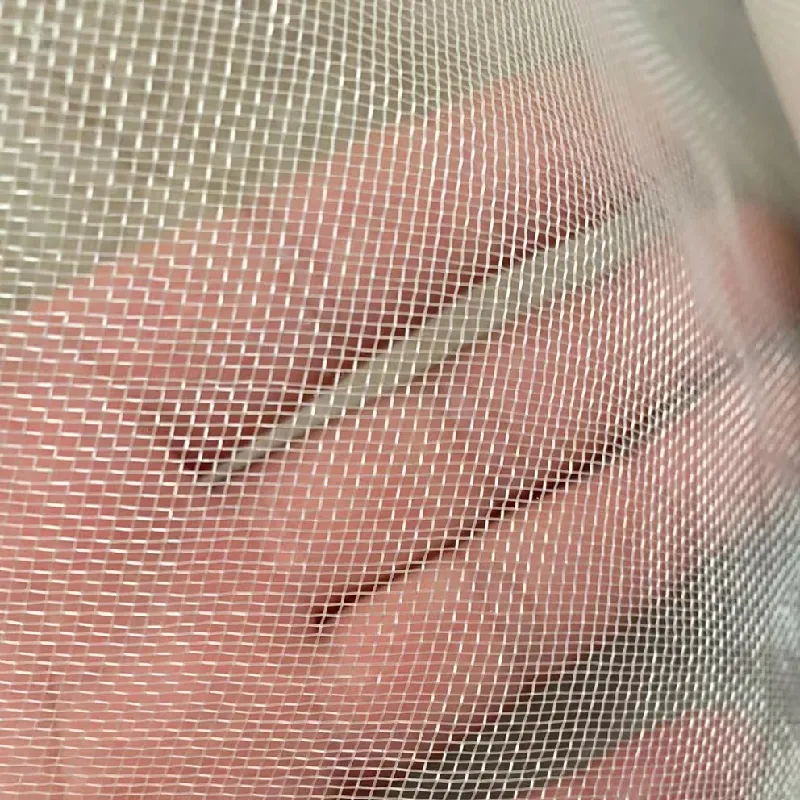

Exploring the Benefits and Applications of Safety Mesh in Modern Industries

Understanding Safety Mesh A Comprehensive Guide

Safety mesh, often referred to as protective mesh or safety nets, is a critical component in various industries, providing essential safety measures to protect workers and ensure the integrity of operations. As industries evolve and the demand for safety increases, understanding safety mesh becomes imperative for employers, workers, and safety professionals alike. This article explores the importance, types, applications, and best practices related to safety mesh.

Importance of Safety Mesh

Safety mesh plays a vital role in safeguarding workers from potential accidents and injuries. In construction sites, for instance, the risk of falling objects is significant. Installing safety mesh around perimeters or scaffolding can minimize the chances of individuals being struck by falling debris, thereby reducing the likelihood of severe injuries or fatalities. Additionally, safety mesh helps to contain hazards, like loose materials, thereby maintaining a cleaner and safer working environment.

Furthermore, safety mesh is essential in ensuring compliance with legal safety standards. Many countries have strict regulations regarding workplace safety, and failure to meet these standards can result in hefty fines and legal repercussions. By utilizing safety mesh appropriately, companies can not only protect their employees but also demonstrate their commitment to safety and compliance.

Types of Safety Mesh

Safety mesh comes in various forms, each designed for specific applications and environments. Some of the most common types include

1. Construction Safety Mesh Often made from durable materials such as polyester or polypropylene, this type of mesh is used on construction sites to prevent debris from falling and to protect workers below. It can be easily installed on scaffolding or as a perimeter enclosure.

2. Debris Netting This is a lightweight option that is ideal for preventing small debris from falling and causing injury. It is commonly used in building renovations and scaffolding installations.

3. Bird and Animal Safety Mesh Used in agricultural settings and around wildlife reserves, this type of mesh prevents unwanted animals from entering crop fields or protects endangered species from human activity.

4. Industrial Safety Mesh Primarily used in factories and warehouses, industrial safety mesh protects machinery and equipment from accidental contact with personnel while providing ventilation and visibility.

Each type of safety mesh is designed to handle specific conditions, and understanding these distinctions is crucial for selecting the right mesh for the job.

safety mesh

Applications of Safety Mesh

The applications of safety mesh span various industries, including construction, agriculture, manufacturing, and even sports. In construction, safety mesh is primarily utilized to prevent falling objects and provide a protective barrier for workers engaged in high-risk activities. In agriculture, it is used to safeguard crops and livestock from predators, ensuring a more controlled environment for farming.

In manufacturing and warehousing, safety mesh serves to protect equipment and maintain a safer workspace. Many factories use safety mesh around machines to prevent accidental contact with moving parts, which is vital for worker safety. In sports, safety mesh can be found in various formats, such as protective netting in baseball fields, to prevent stray balls from posing a threat to spectators.

Best Practices for Implementing Safety Mesh

To effectively utilize safety mesh, organizations must adopt best practices

1. Conduct Risk Assessments Organizations should evaluate their specific environments and identify the potential risks they face. A thorough risk assessment will guide the selection of the appropriate type of safety mesh.

2. Regular Inspections and Maintenance Safety mesh should be routinely inspected for signs of wear and tear. Any damaged sections should be repaired or replaced immediately to ensure continued protection.

3. Training for Workers Employees must be trained on the proper use and importance of safety mesh. Understanding how to operate safely in an environment with safety mesh can further mitigate risks.

4. Compliance with Standards Companies must adhere to local safety regulations and standards regarding the use of safety mesh. This includes using certified materials and ensuring that installations meet safety requirements.

Conclusion

Safety mesh is an integral component of workplace safety, serving to protect workers, machinery, and materials across various industries. By understanding its importance, types, and applications, and by following best practices for implementation, organizations can create safer working environments. Ultimately, the use of safety mesh not only enhances safety but also promotes a culture of responsibility and respect for worker well-being in any industry.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025