-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Improving Safety Measures in Netting Construction for Enhanced Worker Protection

Safety Netting in Construction Ensuring Comprehensive Protection

In the construction industry, ensuring the safety of workers is paramount. One essential component of safety strategies is the use of safety netting. Safety netting serves as a vital protective measure, particularly in environments where there is a risk of falling from heights. In this article, we will explore what safety netting is, its importance in construction, various types available, and best practices for its installation and maintenance.

What is Safety Netting?

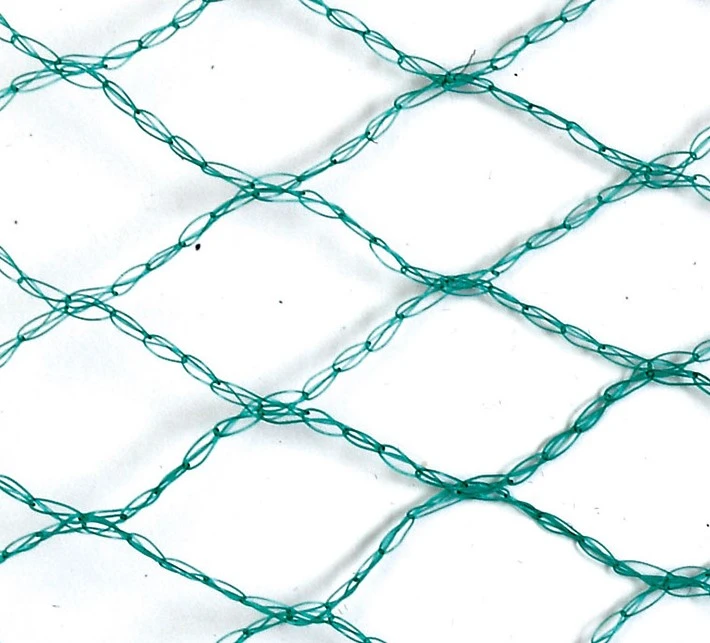

Safety netting refers to a mesh material that is designed to capture falling objects or personnel, preventing serious injuries and fatalities. Typically made from synthetic materials such as polypropylene or nylon, safety nets can vary in size, strength, and design, depending on their intended use. They are strategically placed to create a barrier around work areas, particularly where there are elevated platforms, scaffolding, or other high-risk zones.

The Importance of Safety Netting

The construction sector is notorious for its high rates of workplace accidents, particularly those resulting from falls. According to the Occupational Safety and Health Administration (OSHA), falls are one of the leading causes of death in the construction industry. To combat this alarming statistic, safety netting serves not only as a preventive measure but also as a crucial component of a comprehensive safety plan.

The benefits of safety netting extend beyond just protecting workers. Effective use of safety nets can lead to improved productivity, as workers feel more secure and are able to focus on their tasks without fear of falling. Additionally, safety netting can provide a means of protecting equipment and materials, minimizing potential damage that could arise from falling debris.

Types of Safety Netting

There are several types of safety netting available for construction purposes, each designed to meet specific needs

1. Fall Arrest Nets Designed to catch individuals if they fall, these nets are typically installed below elevated workspaces. They are engineered to withstand significant impacts and are crucial in preventing serious injuries.

safety netting construction

2. Debris Nets These nets are used to capture falling tools, materials, and debris from construction sites. They are installed around scaffolding, platforms, and building perimeters to protect ground-level workers and pedestrians.

3. Safety Barriers Some nets act as barriers to prevent overcrowding or unauthorized entry into hazardous areas. These can be particularly useful around edges of buildings or scaffolding.

Best Practices for Installation and Maintenance

To ensure that safety netting is effective, proper installation and maintenance are essential

- Installation Safety nets should be installed by qualified personnel who understand the specifications and safety standards required. Nets should be placed with minimal sag and securely anchored to withstand expected loads.

- Regular Inspection Regular checks should be conducted to ensure the integrity of the netting. Inspect for wear and tear, tears, or any signs of damage that could compromise safety.

- Training Workers It is crucial to educate workers about the significance of safety netting and how to work safely when it is in place. This includes understanding its limitations and recognizing when additional measures, such as harnesses or guardrails, are necessary.

- Clear Protocols Establish clear guidelines for the use of safety nets, including when they should be deployed and how to follow their maintenance schedules.

Conclusion

In conclusion, safety netting is an indispensable aspect of construction safety that protects workers, equipment, and the general public. By understanding its importance, types, and best practices, construction companies can reduce the risks associated with falls and contribute to a safer working environment. Ultimately, a proactive approach to safety not only saves lives but also enhances overall productivity, leading to a successful and sustainable construction process.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025