-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

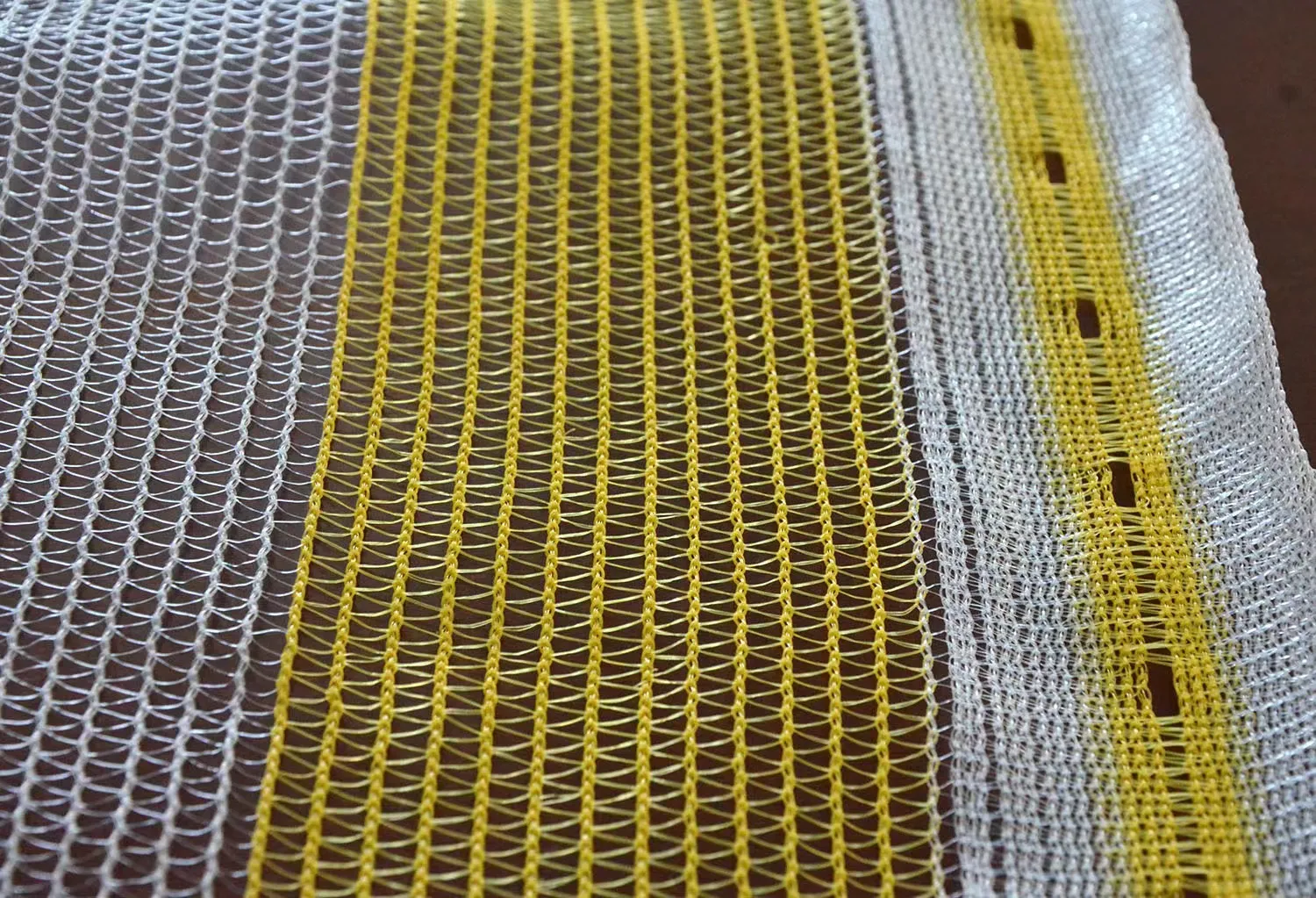

Durable Stainless Steel Mesh for Various Screening Applications and Solutions

The Versatile Applications of Screen Stainless Steel Mesh

Stainless steel mesh has emerged as an essential material across various industries due to its unique combination of strength, durability, and corrosion resistance. Among its many forms, screen stainless steel mesh stands out for its versatility and broad range of applications. This article explores the characteristics, benefits, and uses of stainless steel mesh, highlighting why it has become a go-to material in numerous fields.

Characteristics of Stainless Steel Mesh

Stainless steel mesh is crafted from stainless steel wires that are woven together in a grid pattern, resulting in a strong yet flexible product. It comes in a variety of mesh sizes and wire diameters, catering to different filtration and screening requirements. The primary characteristics that make stainless steel mesh a preferred choice include

1. Corrosion Resistance Stainless steel has a high resistance to rust and corrosion, making it ideal for outdoor applications and environments exposed to moisture, chemicals, or high temperatures.

2. Strength and Durability The inherent strength of stainless steel allows mesh to withstand significant mechanical stresses, ensuring longevity and reliability in demanding applications.

3. Ease of Maintenance Stainless steel mesh is easy to clean and can be used in applications that require frequent sanitation, such as food and pharmaceutical industries.

4. Aesthetic Appeal Its sleek and shiny appearance also makes stainless steel mesh a popular choice for architectural applications where both function and style are important.

Benefits of Using Screen Stainless Steel Mesh

The benefits of screen stainless steel mesh extend beyond its physical properties. Here are several advantages that contribute to its widespread use

- Enhanced Filtration Efficiency The precision of the mesh openings allows for effective filtration and separation of particles, making it a vital component in industries like water treatment, chemical processing, and mining.

- Customizability Stainless steel mesh can be manufactured to meet specific requirements, such as custom sizes, shapes, and mesh patterns, allowing it to fit seamlessly into various systems

.screen stainless steel mesh

- Cost-Effectiveness While stainless steel may have a higher upfront cost compared to other materials, its durability and low maintenance requirements result in a lower total cost of ownership over time.

- Eco-Friendly Stainless steel is recyclable, contributing to environmentally sustainable practices in industrial settings.

Applications of Screen Stainless Steel Mesh

The applications of screen stainless steel mesh are vast and varied, with some of the most common uses including

1. Construction and Architecture In the construction industry, stainless steel mesh can be used for reinforcing concrete, as decorative elements, or as infill panels in facades. Its durability and modern aesthetic appeal make it a favorite among architects.

2. Filtration and Separation In industries such as water treatment, oil and gas, and pharmaceuticals, stainless steel mesh is used for filtering liquids and gases, separating different substances, and straining particulate matter.

3. Food Processing The food industry relies heavily on stainless steel mesh for various applications, including sieving, draining, and as protective barriers. Its ability to withstand high temperatures and cleaning processes ensures compliance with hygiene standards.

4. Safety and Security Screen stainless steel mesh is often used in safety screens, protective barriers, and security fencing. Its strength makes it effective in preventing unauthorized access while allowing visibility.

5. Agriculture In agriculture, stainless steel mesh is used in fencing, animal enclosures, and even in the construction of silos and storage facilities, providing protection against pests while allowing adequate airflow.

Conclusion

Screen stainless steel mesh is a remarkable material, offering a combination of functionality, strength, and aesthetic appeal. Its resistance to corrosion and durability makes it suitable for a wide range of applications in construction, filtration, food processing, safety, and agriculture. As industries continue to evolve, the demand for innovative and reliable materials like stainless steel mesh will undoubtedly grow, solidifying its place as a crucial component across many sectors. Whether you’re involved in construction, manufacturing, or any other industry, understanding the benefits and applications of screen stainless steel mesh can help you harness its potential for improved performance and efficiency.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025