-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

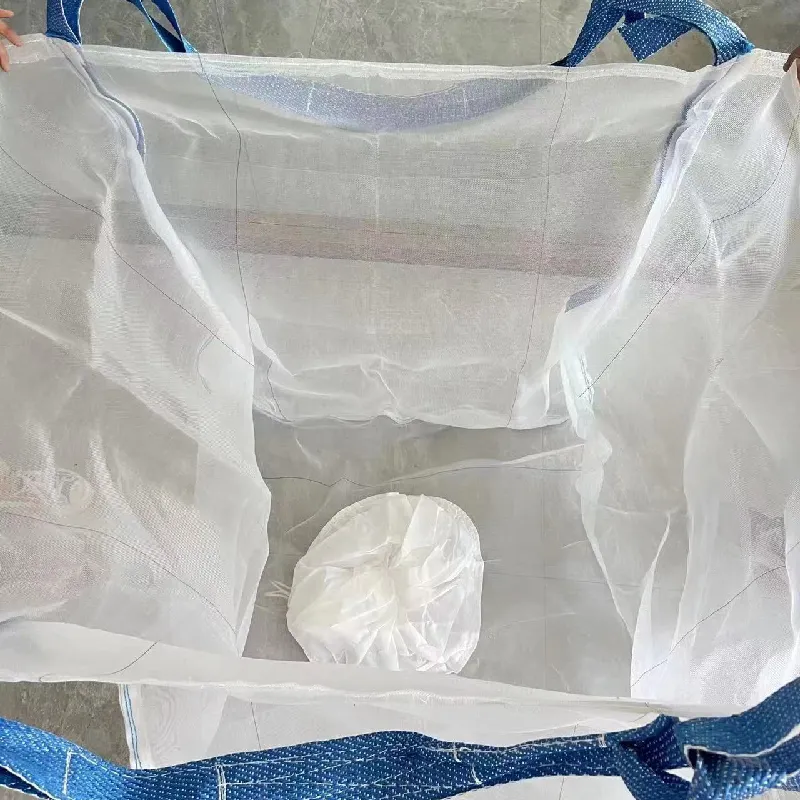

screen steel mesh

Understanding Screen Steel Mesh Applications and Benefits

Screen steel mesh is a versatile and essential product widely utilized in various industries, including construction, mining, agriculture, and manufacturing. Its durability, strength, and adaptability make it an ideal choice for filtering, screening, and separating materials. This article delves into the key features, applications, and benefits of screen steel mesh, highlighting its significance in different sectors.

What is Screen Steel Mesh?

Screen steel mesh, commonly known as wire mesh or welded wire screens, consists of interconnected strands of steel wire that are woven or welded together to form a grid. The mesh is available in various sizes, shapes, and wire thicknesses, allowing it to cater to a wide range of applications. Screen steel mesh can be made from stainless steel, carbon steel, or other alloys, depending on the specific requirements, such as corrosion resistance or structural strength.

Key Features of Screen Steel Mesh

1. Durability and Strength Steel is known for its high tensile strength and resistance to deformation. Screen steel mesh is engineered to withstand heavy loads and harsh environmental conditions, making it a reliable choice in demanding applications.

2. Versatility This type of mesh can be tailored to meet specific needs by adjusting the wire diameter, mesh opening, and overall dimensions. It is suitable for various applications, from mining and filtration to construction and architectural designs.

3. Corrosion Resistance Stainless steel mesh products are particularly popular due to their resistance to rust and corrosion, which extends their lifespan and reduces maintenance costs.

Applications of Screen Steel Mesh

1. Construction Industry In construction, screen steel mesh is commonly used in concrete reinforcement, offering structural support to walls, floors, and ceilings. It enhances the durability of concrete structures and prevents cracking.

screen steel mesh

2. Mining and Aggregates The mining industry relies heavily on screen steel mesh for sifting and grading various minerals and ores. The mesh helps separate fine materials from coarse ones, improving the efficiency of mineral extraction processes.

3. Agriculture In agriculture, screen steel mesh is utilized for creating barriers, fencing, and support structures for plants. It facilitates proper air circulation and light penetration while keeping pests at bay.

4. Manufacturing The manufacturing sector uses screen steel mesh for various filtration applications, such as liquid and gas filtration, as well as in the production of components that require specific dimensional tolerances.

5. Home and Garden Screen steel mesh is also popular among DIY enthusiasts for a range of home and garden projects, including screening in patios, pool areas, or creating decorative architectural elements.

Benefits of Using Screen Steel Mesh

1. Cost-Effective Due to its long lifespan and low maintenance requirements, screen steel mesh can be a cost-effective solution in the long run. Its durability ensures that it won't need frequent replacements like other materials.

2. High Efficiency The design of screen steel mesh allows for optimal airflow and fluid movement, making it efficient for filtering and separating materials. This efficiency translates into improved productivity across various applications.

3. Environmental Impact By using materials that are recyclable and often made from recycled steel, screen steel mesh contributes to sustainability efforts. Its longevity also reduces waste generation.

Conclusion

Screen steel mesh is an indispensable material across numerous industries. Its strength, versatility, and cost-effectiveness make it a favored choice for applications ranging from construction to mining and beyond. As industries continue to evolve and expand, the demand for reliable steel mesh solutions will only grow, underscoring the importance of screen steel mesh in modern infrastructure and manufacturing processes. Understanding its characteristics and applications can help professionals make informed decisions when selecting materials for their specific needs.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025