-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 26, 2025 03:13

Back to list

Welded Gabion Box 2x1x1 Hot Dipped Galvanized Welded Mesh Gabion

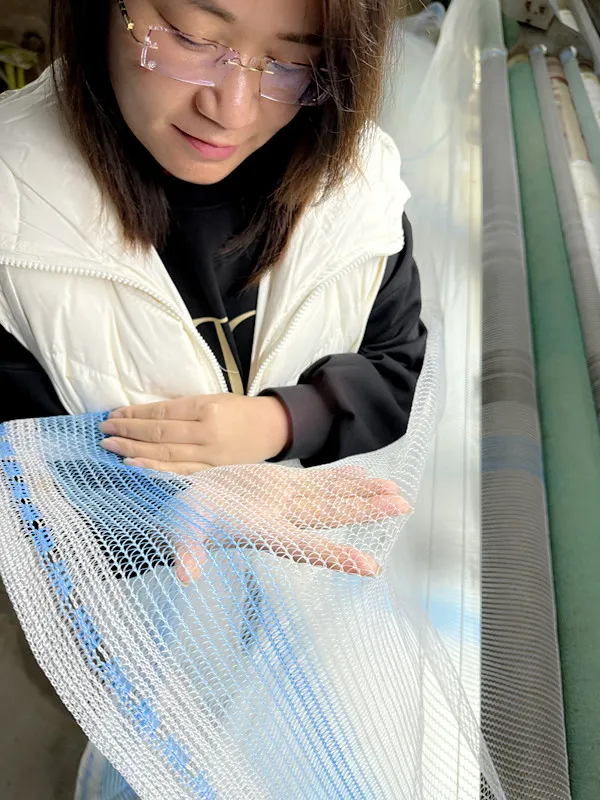

Spring steel wire mesh has emerged as a crucial component in various industrial applications, gaining prominence due to its unique properties and characteristics. In industries where strength, flexibility, and durability are paramount, spring steel wire mesh stands out as an unparalleled choice. This article explores the distinctive features of spring steel wire mesh, its applications, and why it is a product that is both highly specialized and widely trusted by experts.

In terms of expertise, manufacturing spring steel wire mesh involves precision engineering and extensive knowledge of metallurgical processes. Producing high-quality spring steel requires meticulous control of carbon composition and heat treatment processes. This expertise is essential to enhance the steel's properties, ensuring that it meets the demanding specifications required by various industries. This authority is established through rigorous quality control and adherence to international standards, making spring steel wire mesh a product synonymous with reliability and excellence. Trustworthiness in spring steel wire mesh is verified through certifications and testaments from industry experts and users who have consistently chosen this material for their demanding applications. The mesh is subjected to a series of stringent quality tests, including fatigue resistance, impact toughness, and load-bearing capability, ensuring that it meets all requisite safety and performance standards. These certifications not only confirm the product's credibility but also fortify its position as a preferred choice among discerning professionals. For companies looking to invest in materials that offer superior performance, the choice of spring steel wire mesh is strengthened by its eco-friendly aspects. Spring steel is recyclable, which aligns with the growing global emphasis on sustainable practices. By choosing recyclable materials, industries can contribute to reducing their carbon footprint, fostering environmental responsibility, and building a sustainable future. In conclusion, spring steel wire mesh is a product that transcends ordinary materials with its exceptional strength, flexibility, and durability. Its application in various sectors demonstrates its adaptability and the trust it has earned among experts. With a foundation built on expertise and an ongoing commitment to quality, spring steel wire mesh continues to uphold its reputation as an authoritative solution in industrial applications. Choosing this material not only reflects a commitment to excellence but also underscores a consciousness towards sustainable and environmentally responsible practices.

In terms of expertise, manufacturing spring steel wire mesh involves precision engineering and extensive knowledge of metallurgical processes. Producing high-quality spring steel requires meticulous control of carbon composition and heat treatment processes. This expertise is essential to enhance the steel's properties, ensuring that it meets the demanding specifications required by various industries. This authority is established through rigorous quality control and adherence to international standards, making spring steel wire mesh a product synonymous with reliability and excellence. Trustworthiness in spring steel wire mesh is verified through certifications and testaments from industry experts and users who have consistently chosen this material for their demanding applications. The mesh is subjected to a series of stringent quality tests, including fatigue resistance, impact toughness, and load-bearing capability, ensuring that it meets all requisite safety and performance standards. These certifications not only confirm the product's credibility but also fortify its position as a preferred choice among discerning professionals. For companies looking to invest in materials that offer superior performance, the choice of spring steel wire mesh is strengthened by its eco-friendly aspects. Spring steel is recyclable, which aligns with the growing global emphasis on sustainable practices. By choosing recyclable materials, industries can contribute to reducing their carbon footprint, fostering environmental responsibility, and building a sustainable future. In conclusion, spring steel wire mesh is a product that transcends ordinary materials with its exceptional strength, flexibility, and durability. Its application in various sectors demonstrates its adaptability and the trust it has earned among experts. With a foundation built on expertise and an ongoing commitment to quality, spring steel wire mesh continues to uphold its reputation as an authoritative solution in industrial applications. Choosing this material not only reflects a commitment to excellence but also underscores a consciousness towards sustainable and environmentally responsible practices.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025