-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 20, 2025 11:44

Back to list

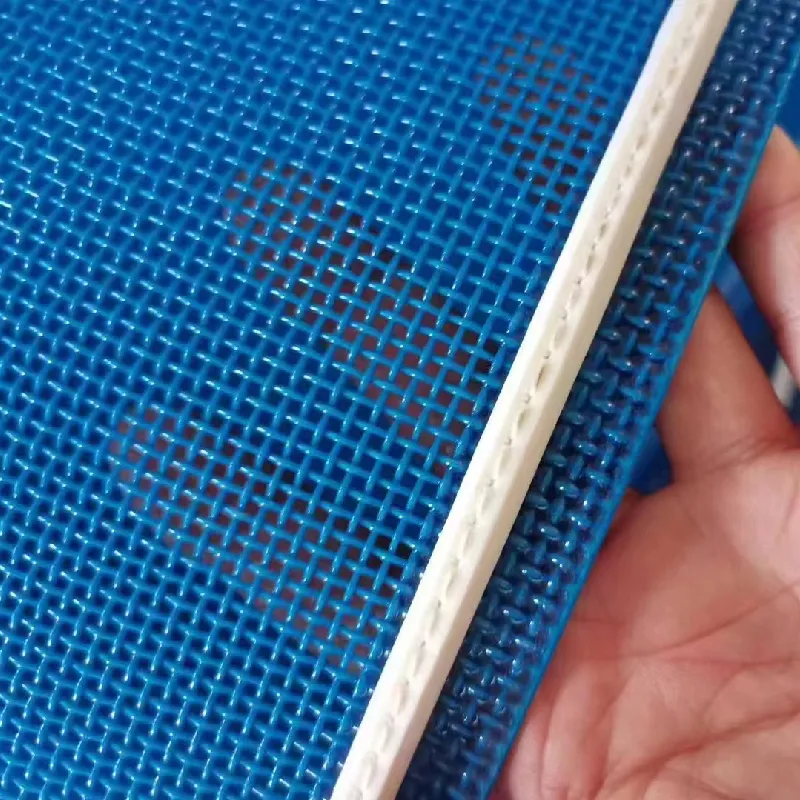

Professional Factory Iron Wire Mesh Cold Plated Electric Welding Mesh

Spring steel wire mesh stands out as a remarkable material in industries ranging from construction to automotive engineering. Its unique combination of durability, flexibility, and strength makes it an essential component for various applications. With years of hands-on experience, I can confidently assert that spring steel wire mesh offers advantages that are unmatched by other types of wire meshes.

The authoritative aspect of spring steel wire mesh is backed by its widespread acceptance across multiple industries. Manufacturers often adhere to international quality standards, further bolstering its reputation as a trustworthy product. In sectors where safety and reliability are paramount, such as aerospace and defense, the use of spring steel wire mesh is a testament to its unparalleled performance. Certification by recognized industry bodies further enhances its credentials, making it a go-to choice for professionals worldwide. When evaluating the trustworthiness of spring steel wire mesh, it is essential to consider the consistent performance it delivers. Its proven track record in demanding applications instills confidence among users, knowing that it will withstand the test of time. Unlike some materials that require frequent replacements, spring steel wire mesh offers a long-term solution, reducing costs and ensuring that safety and efficiency are maintained. In conclusion, spring steel wire mesh is a versatile and reliable material that meets the needs of various industries with precision and efficacy. Its combination of elasticity, durability, and resistance to environmental stressors makes it an invaluable asset in engineering and construction projects. By adhering to rigorous manufacturing practices and industry standards, it continues to uphold its reputation for excellence, making it a preferred choice for professionals seeking a trustworthy and authoritative solution.

The authoritative aspect of spring steel wire mesh is backed by its widespread acceptance across multiple industries. Manufacturers often adhere to international quality standards, further bolstering its reputation as a trustworthy product. In sectors where safety and reliability are paramount, such as aerospace and defense, the use of spring steel wire mesh is a testament to its unparalleled performance. Certification by recognized industry bodies further enhances its credentials, making it a go-to choice for professionals worldwide. When evaluating the trustworthiness of spring steel wire mesh, it is essential to consider the consistent performance it delivers. Its proven track record in demanding applications instills confidence among users, knowing that it will withstand the test of time. Unlike some materials that require frequent replacements, spring steel wire mesh offers a long-term solution, reducing costs and ensuring that safety and efficiency are maintained. In conclusion, spring steel wire mesh is a versatile and reliable material that meets the needs of various industries with precision and efficacy. Its combination of elasticity, durability, and resistance to environmental stressors makes it an invaluable asset in engineering and construction projects. By adhering to rigorous manufacturing practices and industry standards, it continues to uphold its reputation for excellence, making it a preferred choice for professionals seeking a trustworthy and authoritative solution.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025