-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

High-Quality Stainless Steel Filters for Optimal Filtration Solutions

Stainless Steel Filters Durable Solutions for Filtration Needs

Stainless steel filters are increasingly gaining popularity across various industries due to their durability, corrosion resistance, and adaptability to different environments. They serve as essential components in numerous applications, from water filtration to food processing, and even in chemical manufacturing. This article will explore the significance of stainless steel filters, their advantages, and the diverse applications they serve.

One of the primary reasons businesses choose stainless steel filters is their long-lasting nature. Made from alloys like 304 or 316 stainless steel, these filters can withstand high temperatures and pressures without losing structural integrity. Unlike conventional filters, which may degrade over time due to exposure to moisture, chemicals, or extreme temperatures, stainless steel filters maintain their performance over an extended period. This durability translates into fewer replacements and lower operational costs, making them a cost-effective solution in the long run.

Corrosion resistance is another significant advantage of stainless steel filters. In industries such as food and beverage, pharmaceutical, and petrochemical, exposure to various acids and salts can compromise the functionality of standard filters. Stainless steel, however, is engineered to resist such corrosive environments, ensuring that the filtration process remains efficient and reliable. This characteristic not only protects the integrity of the filter but also guarantees that the end product is free from contamination.

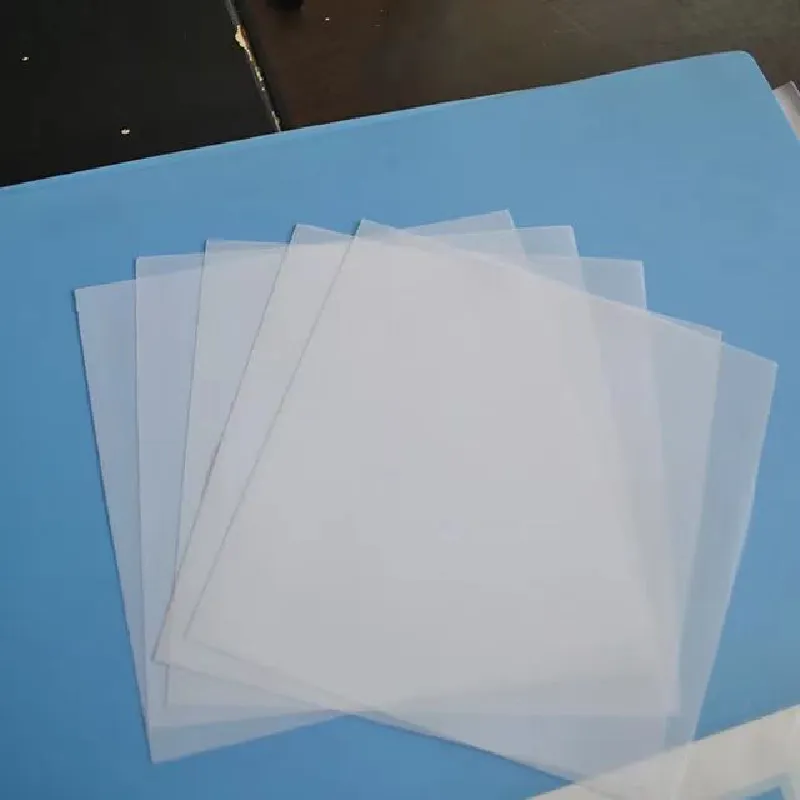

stainless steel filters

The versatility of stainless steel filters further enhances their appeal. They can be designed in various configurations, including mesh screens, disc filters, and cartridge systems, accommodating specific filtration needs. This adaptability allows industries to tailor their filtration systems to their unique requirements, whether it’s for removing particulates from liquids or gases. Furthermore, stainless steel filters can be easily cleaned and reused, making them an eco-friendly choice compared to single-use filters that contribute to waste.

In addition to their application in industrial settings, stainless steel filters are also critical in residential and commercial water filtration systems. As consumers become increasingly aware of the quality of their drinking water, the demand for reliable filtration solutions continues to grow. Stainless steel filters provide a robust option for removing contaminants such as chlorine, sediment, and other impurities from water, ensuring safe and clean drinking water for households and businesses alike.

Moreover, the application of stainless steel filters extends into innovative technologies, including wastewater treatment and air filtration systems. With the ongoing global focus on sustainability and environmental protection, these filters play a crucial role in purifying water and minimizing air pollutants, thus contributing to cleaner ecosystems.

In summary, stainless steel filters represent a vital advancement in filtration technology. Their durability, corrosion resistance, and flexibility make them ideal for a wide range of applications across various industries. As the demand for quality filtration continues to rise, investing in stainless steel filters is not just a practical choice but also a step towards sustainable practices. Whether in industrial processes or everyday water filtration, these filters are poised to remain an essential component of safe and efficient systems.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025