High-Quality Stainless Steel Filters and Strainers for Efficient Filtration

The Efficiency of Stainless Steel Filters and Strainers

In various industries, the functionality of filtration systems plays a pivotal role in maintaining the quality and purity of liquids. Stainless steel filters and strainers have emerged as essential components in this domain, offering durability, efficiency, and reliability. This article delves into the advantages of stainless steel filters and strainers and their applications across different sectors.

The Efficiency of Stainless Steel Filters and Strainers

One of the primary functions of stainless steel filters is to remove impurities and particles from liquids. They effectively filter out contaminants ranging from large debris to microscopic particles, ensuring that the final product meets industry standards. In sectors such as food and beverage, pharmaceuticals, and water treatment, the cleanliness of the final output is critical. Stainless steel filters ensure that the filtration process does not introduce any undesired substances, maintaining the integrity of the product.

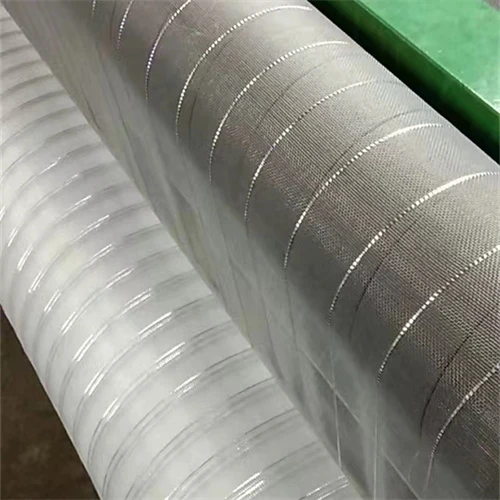

stainless steel filters strainers

Strainers, on the other hand, are designed to protect equipment such as pumps, valves, and meters from debris that could cause damage or malfunction. By preventing large particles from entering the system, stainless steel strainers enhance the longevity of the machinery, promoting smoother operations. This is particularly vital in industries like oil and gas, where even minor impurities can lead to significant operational challenges.

The versatility of stainless steel filters and strainers is also noteworthy. They come in various mesh sizes and configurations, allowing customization for specific applications. Whether it’s a fine mesh for micro-filtration or a coarser option for larger particles, stainless steel filters can be tailored to meet precise filtration needs, ensuring optimal performance in any process.

Maintenance is another critical aspect where stainless steel filters shine. Their robust construction makes them easy to clean and maintain, further enhancing their cost-effectiveness. Regular maintenance can be performed by simply removing the filter or strainer, cleaning it, and reinstalling it within a short downtime. This efficiency is especially beneficial in industrial settings, where time is often equated with money.

In conclusion, stainless steel filters and strainers are indispensable tools across numerous industries. Their durability, efficiency, and adaptability make them suitable for a wide range of applications, ensuring that filtration processes are both effective and economical. As industries continue to prioritize quality and operational efficiency, the reliance on stainless steel filtration solutions is only expected to grow, solidifying their place in the future of filtration technology.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025