Stainless Steel Filters | Durable Wire Mesh, Custom OEM

Inside the world of 304 Stainless Steel Filter Screens: what really matters

If you’ve ever specced stainless steel filters for a tough process line, you know the stakes: uptime, cleanability, and honest-to-goodness particle retention. The product here—304 Stainless Steel Filter Screen: High Temperature Resistance & Easy to Clean—comes out of China and, to be honest, it’s been showing up on more RFQs than I expected this year.

What’s trending (and why it matters)

Two macro trends: higher solids loading in battery slurries and more aggressive CIP/SIP regimes in hygienic plants. Both push buyers toward stainless steel filters with tighter micron accuracy, better fatigue resistance, and repeatable cleanability. In fact, many customers say they want “wash-and-go” instead of frequent changeouts.

How it’s made: a quick process flow

- Materials: 304 base (optional 316L for chlorides), wire per ASTM A580; sheet components per ASTM A240.

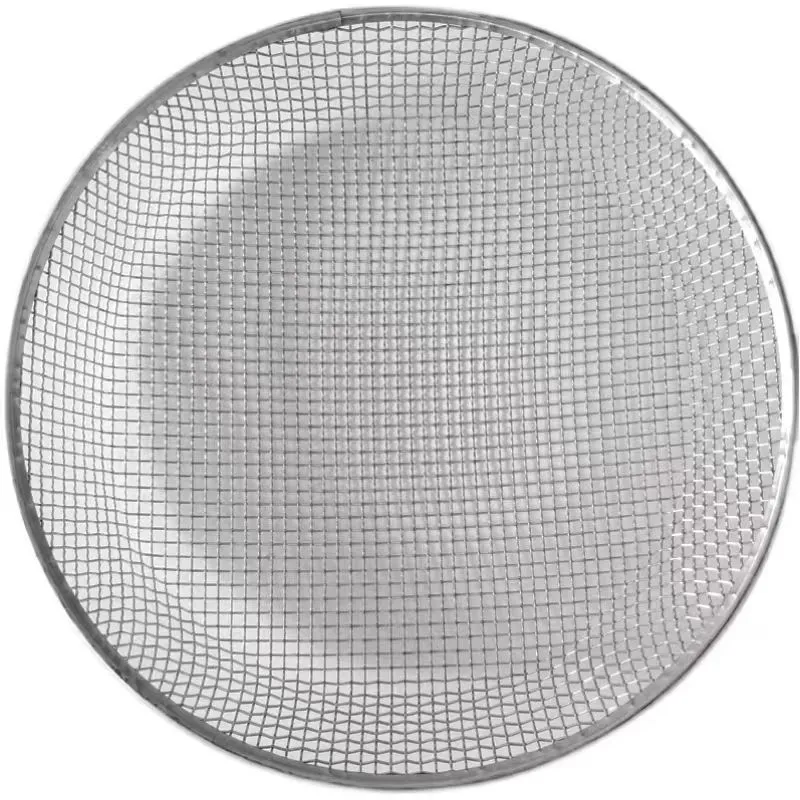

- Weaving: plain/twill/dutch weave to ISO 9044; optional multi-layer sintering (diffusion-bonded) for rigidity.

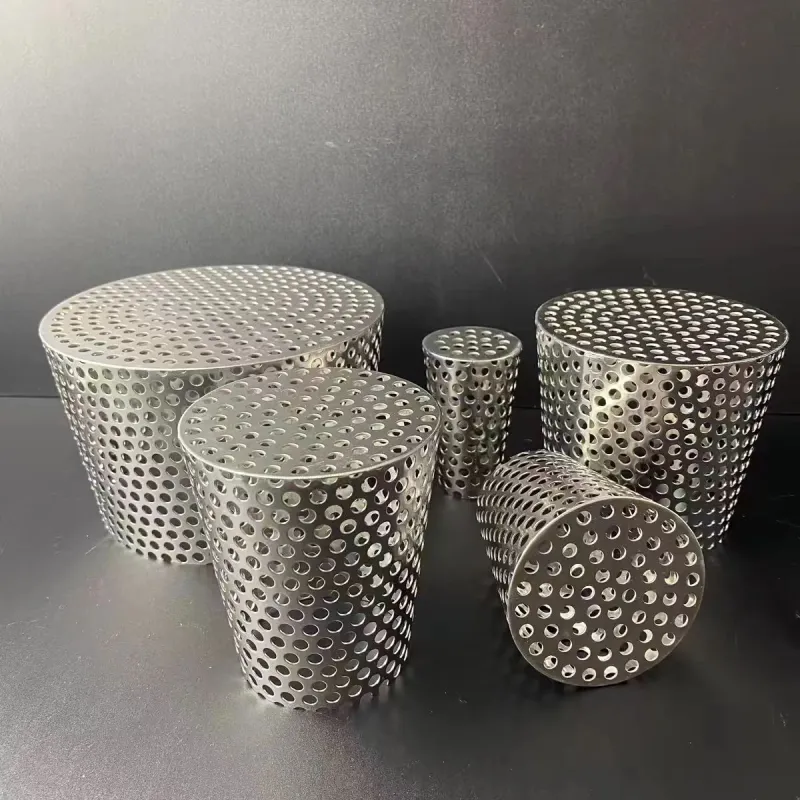

- Forming: cutting, slitting, rolling, seam welding; filter cores and cartridges are built from braided/woven mesh.

- Heat treatment: stress relief for dimensional stability; optional sintered packs.

- Testing: bubble point and pore size (ASTM F316), multi-pass efficiency (ISO 16889), salt spray (ASTM B117) as required.

- Service life: ≈ 1–5 years depending on ΔP, media, and CIP frequency—real-world use may vary.

Product snapshot and key specs

| Model | 304 Stainless Steel Filter Screen |

| Micron rating | ≈ 5–500 μm (custom to tighter ranges) |

| Temperature | Up to ≈ 450°C dry; process-dependent |

| Pressure | Up to ≈ 2.5 MPa (with sintered packs) |

| Weave options | Plain/Twill/Dutch; multi-layer sintered |

| Cleanability | CIP/SIP, ultrasonic, backwash |

| Compliance | ISO 9001 plant; food contact per EU 1935/2004; typical pharma compatibility with ASME BPE systems |

Where they’re used

Chemicals and petrochem, edible oils, brewing, dairy, water treatment, catalysts, solvent recovery, battery materials, and even fine pigments. Surprisingly, stainless steel filters are now common in lithium cathode lines where slurry stability is everything.

Mini case studies

Food oil refinery: Swapped polymer cartridges for sintered 304 packs; cut changeouts from weekly to quarterly, with ΔP stabilized under 0.12 MPa at nominal flow.

Battery slurry plant: Dutch weave 25 μm layer stack achieved ≈99.5% D50 capture (ISO 16889 bench), improved coating uniformity; operators liked the quick ultrasonic clean.

Vendor comparison (practical view)

| Feature | YJ Wire Mesh (Origin: China) | Typical Distributor | Generic Import |

|---|---|---|---|

| Micron accuracy | Tight; ASTM F316 verified | Good; mixed OEM sources | Varies; limited test data |

| Customization | Cut-to-size, sintered packs, cores | Some; longer lead times | Minimal |

| Certifications | ISO 9001; EU food-contact docs | ISO 9001 (reseller) | Unclear |

| Lead time | ≈ 7–20 days | ≈ 2–6 weeks | Unpredictable |

| Price (indicative) | Competitive | Moderate | Low, with variance |

Customization that actually helps

- Cut circles, discs, and layered packs with spot or seam welding.

- Cartridge cores, perforated support tubes, end caps.

- Edge finishing to reduce fray; passivation for corrosion resistance.

- Documentation packs: material certs, bubble-point reports, and lot traceability.

Real-world feedback

“Backflush cleans in under five minutes.” Another buyer told me, “We expected 316L, but 304 held up fine—no pitting at our chloride levels.” I guess that’s the point: pick the metallurgy for the chemistry, not by habit.

Certifications and standards

Look for ISO 9001 production, test to ASTM F316 and ISO 16889 where applicable, and request EU 1935/2004 food-contact statements for hygienic lines. For pharma skids that use stainless steel filters, aligning with ASME BPE-grade wetted surfaces is wise.

Bottom line: if you need high-temperature stability, easy cleaning, and sane lead times, these 304 screens are a practical, well-documented option—especially when sintered and sized to your frames.

References

- ASTM F316 – Standard Test Methods for Pore Size Characteristics of Membrane Filters.

- ISO 16889 – Hydraulic fluid power filters – Multi-pass method for evaluating filtration performance.

- ASTM A240/A240M – Standard Specification for Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip.

- EU Regulation 1935/2004 – Materials and articles intended to come into contact with food.

-

Anti Hail Net | UV-Stable, High-Strength Orchard ShieldNewsNov.17,2025

-

Anti Bird Netting – UV-Stable, Durable, Humane ProtectionNewsNov.17,2025

-

Welded Wire - Durable, Rust-Resistant Mesh, Custom SizesNewsNov.17,2025

-

Garden Mesh Sun Shade – UV-Resistant, Durable, Custom SizesNewsNov.17,2025

-

Bird in Net Solution: Humane, UV-Resistant Bird NettingNewsNov.17,2025

-

Stainless Steel Filters: Durable, Washable, High-FlowNewsNov.10,2025