-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jun . 30, 2024 10:30

Back to list

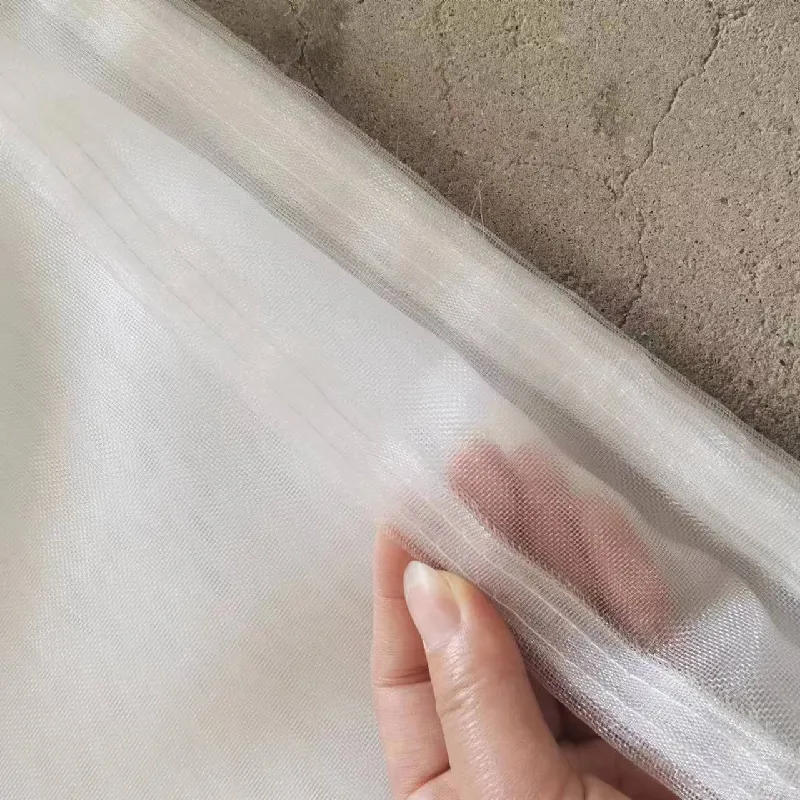

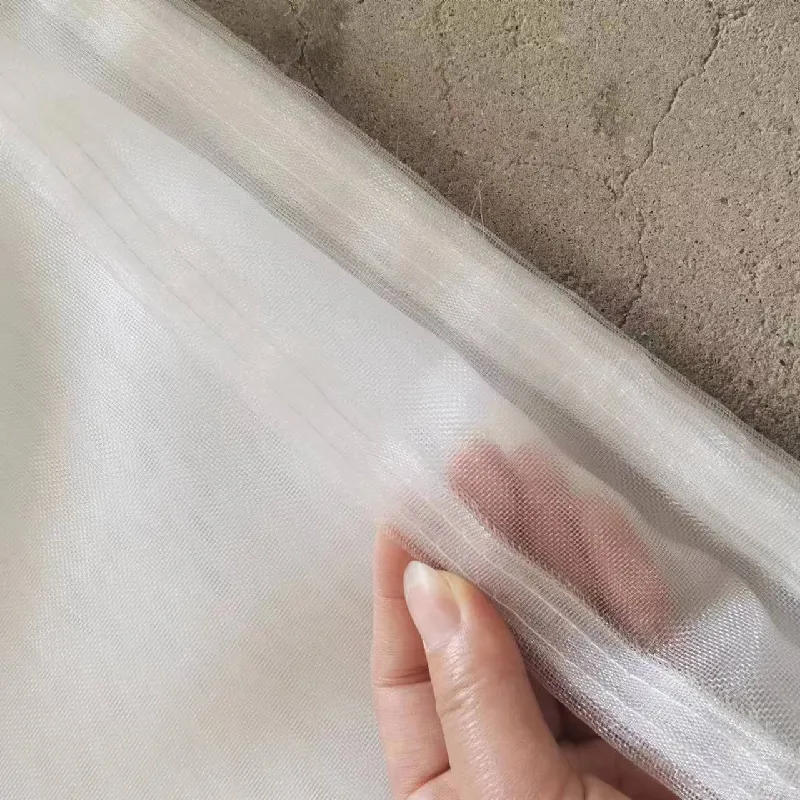

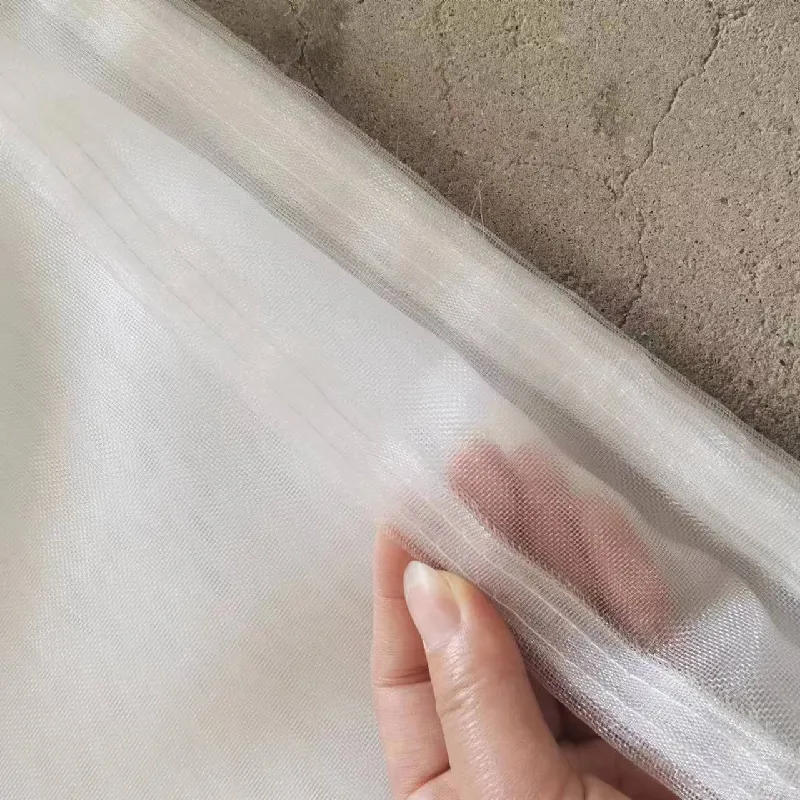

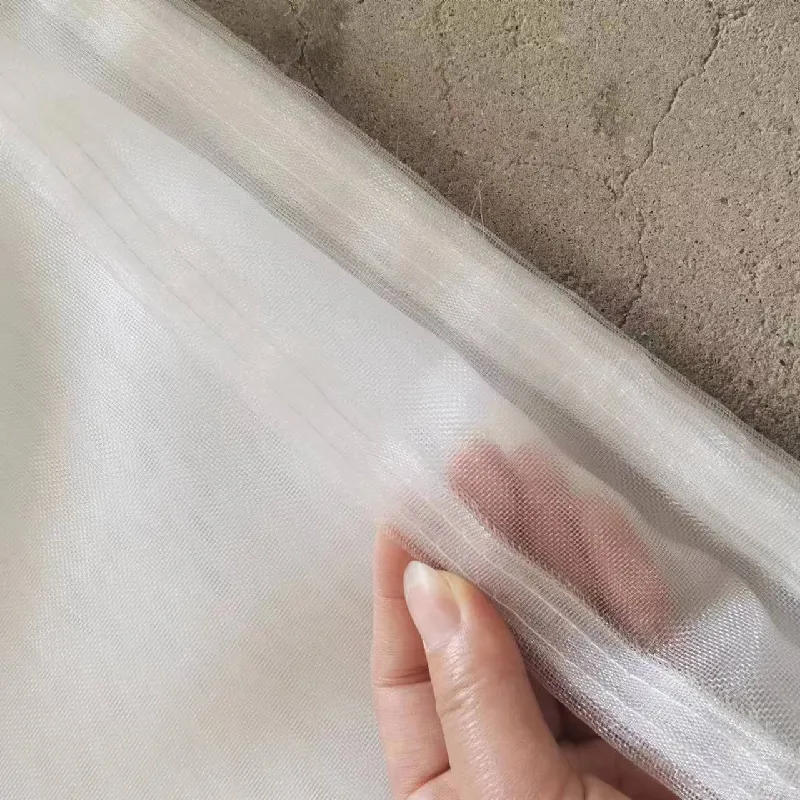

Stainless Steel Screen Filter An Effective Tool for Separation and Filtration

The Versatile Stainless Steel Screen Filter

In the vast array of materials and products used in industrial and domestic applications, stainless steel has long been celebrated for its durability and resistance to corrosion. Among the many uses of this remarkable metal is the stainless steel screen filter, a component that quietly revolutionizes processes across various sectors.

The stainless steel screen filter is essentially a mesh made from interwoven stainless steel threads. This mesh is then mounted onto a rigid frame, creating a sturdy filtration device. The size of the mesh can vary, allowing for different levels of filtration—coarse, medium, or fine, depending on the application's needs.

One of the most prominent industries where stainless steel screen filters shine is in the processing of fluids. In oil refineries, these filters are indispensable for removing impurities that could damage machinery or reduce the quality of the final product. Similarly, in wastewater treatment facilities, they play a crucial role in trapping solid particles before clean water is discharged or recycled.

Stainless steel screen filters also find extensive use in the food and pharmaceutical industries. Here, they ensure that ingredients are free from contaminants, preserving both the integrity of the product and the safety of consumers. For instance, during the brewing of beer, screens remove hop residues, ensuring a clear and crisp end product.

The agricultural sector benefits from stainless steel screen filters too

The agricultural sector benefits from stainless steel screen filters too The agricultural sector benefits from stainless steel screen filters too

The agricultural sector benefits from stainless steel screen filters too

The agricultural sector benefits from stainless steel screen filters too

The agricultural sector benefits from stainless steel screen filters too stainless steel screen filter. In advanced irrigation systems, these filters prevent dirt particles from clogging nozzles, maintaining the efficiency of water delivery to crops. This not only conserves water but also supports sustainable farming practices.

Moreover, in laboratories and medical facilities, stainless steel screen filters provide essential separation during experiments and procedures, helping to maintain sterile environments and accurate diagnoses.

It is worth mentioning the environmental impact of stainless steel screen filters. Being reusable and long-lasting, they contribute to reducing waste compared to disposable filter options. However, it's important to note that their production does require energy and resources, highlighting the need for responsible manufacturing processes.

In conclusion, the stainless steel screen filter, with its robust construction and adaptable design, serves as a silent workhorse in diverse fields. It enhances processes, ensures product quality, and upholds health standards, all while promoting sustainability through its longevity and recyclability. As technology continues to advance, the potential applications for this humble yet mighty filter can only expand, cementing its place as an essential component in modern industry and everyday life.

stainless steel screen filter. In advanced irrigation systems, these filters prevent dirt particles from clogging nozzles, maintaining the efficiency of water delivery to crops. This not only conserves water but also supports sustainable farming practices.

Moreover, in laboratories and medical facilities, stainless steel screen filters provide essential separation during experiments and procedures, helping to maintain sterile environments and accurate diagnoses.

It is worth mentioning the environmental impact of stainless steel screen filters. Being reusable and long-lasting, they contribute to reducing waste compared to disposable filter options. However, it's important to note that their production does require energy and resources, highlighting the need for responsible manufacturing processes.

In conclusion, the stainless steel screen filter, with its robust construction and adaptable design, serves as a silent workhorse in diverse fields. It enhances processes, ensures product quality, and upholds health standards, all while promoting sustainability through its longevity and recyclability. As technology continues to advance, the potential applications for this humble yet mighty filter can only expand, cementing its place as an essential component in modern industry and everyday life.

The agricultural sector benefits from stainless steel screen filters too

The agricultural sector benefits from stainless steel screen filters too

The agricultural sector benefits from stainless steel screen filters too

The agricultural sector benefits from stainless steel screen filters too stainless steel screen filter. In advanced irrigation systems, these filters prevent dirt particles from clogging nozzles, maintaining the efficiency of water delivery to crops. This not only conserves water but also supports sustainable farming practices.

Moreover, in laboratories and medical facilities, stainless steel screen filters provide essential separation during experiments and procedures, helping to maintain sterile environments and accurate diagnoses.

It is worth mentioning the environmental impact of stainless steel screen filters. Being reusable and long-lasting, they contribute to reducing waste compared to disposable filter options. However, it's important to note that their production does require energy and resources, highlighting the need for responsible manufacturing processes.

In conclusion, the stainless steel screen filter, with its robust construction and adaptable design, serves as a silent workhorse in diverse fields. It enhances processes, ensures product quality, and upholds health standards, all while promoting sustainability through its longevity and recyclability. As technology continues to advance, the potential applications for this humble yet mighty filter can only expand, cementing its place as an essential component in modern industry and everyday life.

stainless steel screen filter. In advanced irrigation systems, these filters prevent dirt particles from clogging nozzles, maintaining the efficiency of water delivery to crops. This not only conserves water but also supports sustainable farming practices.

Moreover, in laboratories and medical facilities, stainless steel screen filters provide essential separation during experiments and procedures, helping to maintain sterile environments and accurate diagnoses.

It is worth mentioning the environmental impact of stainless steel screen filters. Being reusable and long-lasting, they contribute to reducing waste compared to disposable filter options. However, it's important to note that their production does require energy and resources, highlighting the need for responsible manufacturing processes.

In conclusion, the stainless steel screen filter, with its robust construction and adaptable design, serves as a silent workhorse in diverse fields. It enhances processes, ensures product quality, and upholds health standards, all while promoting sustainability through its longevity and recyclability. As technology continues to advance, the potential applications for this humble yet mighty filter can only expand, cementing its place as an essential component in modern industry and everyday life. Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025