-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

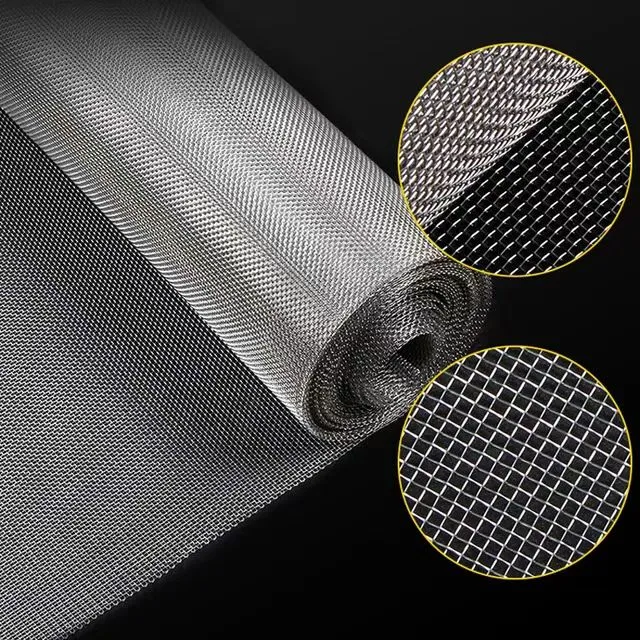

Durable Stainless Steel Mesh Filter for Efficient Filtration Solutions

The Advantages and Applications of Stainless Steel Mesh Filters

Stainless steel mesh filters are widely recognized for their durability and efficiency in various filtration applications. Made from high-quality stainless steel, these filters are designed to withstand harsh conditions while providing exceptional filtering capabilities. With a variety of micron ratings, mesh sizes, and configurations, stainless steel mesh filters are suitable for a range of industries, including food processing, pharmaceuticals, water treatment, and petrochemicals.

One of the primary advantages of stainless steel mesh filters is their corrosion resistance. Unlike other materials, stainless steel is less prone to rust or degradation when exposed to moisture and aggressive chemicals. This property makes it ideal for applications in environments where cleanliness and hygiene are paramount. For instance, in food and beverage processing, stainless steel mesh filters ensure that no foreign particles contaminate the product, thus maintaining safety and quality standards.

Moreover, stainless steel mesh filters are highly durable and can withstand repeated cleaning and maintenance. Unlike disposable filters, which need to be replaced frequently, stainless steel filters can be cleaned and reused, making them a cost-effective solution in the long term. They can handle high temperatures and pressures, which is particularly important in applications like oil filtration or chemical processing where extreme conditions are common.

The Advantages and Applications of Stainless Steel Mesh Filters

Stainless steel mesh filters are particularly popular in the environmental sector, especially for water treatment processes. These filters are used to remove sediments, algae, and other impurities from water sources, ensuring that the treated water meets safety and quality standards. Additionally, stainless steel filters are easier to sanitize compared to plastic or paper filters, adding an extra layer of reassurance in applications where hygiene is critical.

stainless mesh filter

Another significant benefit of stainless steel mesh filters is their eco-friendliness. Given their reusable nature, they minimize waste and reduce the environmental impact associated with disposable filters. As industries increasingly focus on sustainable practices, utilizing stainless steel filters can contribute to green initiatives by lowering the demand for single-use products.

In the pharmaceutical industry, the need for sterilization and contamination-free environments is vital. Stainless steel mesh filters play a crucial role in ensuring that pharmaceutical products are free from particulate matter and microbial contaminants. These filters can handle sterilization processes, such as autoclaving, without losing structural integrity or filtration efficiency.

Beyond these applications, stainless steel mesh filters are also employed in oil and gas industries for separating solids from liquids during extraction and refinement processes. Their durability ensures they can handle the high pressures and temperatures often found in these settings, while their effectiveness in filtering contaminants preserves the quality of the extracted resources.

Despite the numerous advantages, selecting the appropriate stainless steel mesh filter involves careful consideration of various factors, including the specific filtration requirements, flow rates, and the nature of the materials being filtered. When properly selected and maintained, stainless steel mesh filters can significantly enhance the efficiency of a filtration system and prolong service life.

In conclusion, stainless steel mesh filters are versatile and robust solutions for modern filtration needs across multiple industries. Their durability, effectiveness, and eco-friendly nature make them an attractive option for businesses aiming to improve their operational efficiency while adhering to environmental standards. As technology continues to advance, the applications and efficiencies of these filters are likely to expand even further, making them indispensable in the quest for cleaner and safer products.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025