-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

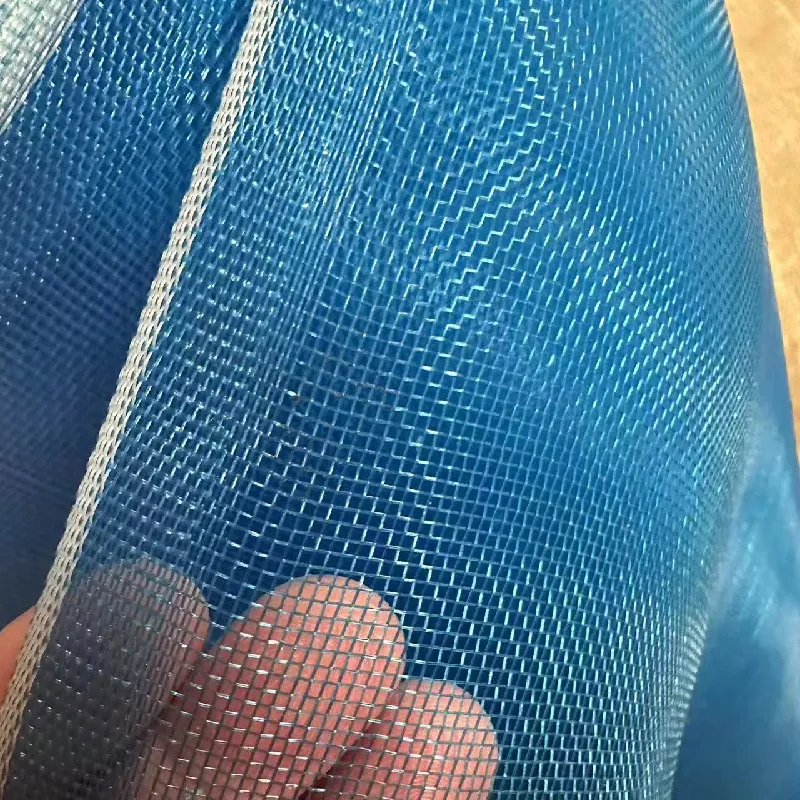

stainless steel filters

The Benefits and Applications of Stainless Steel Filters

Stainless steel filters are becoming an essential component in various industries due to their durability, corrosion resistance, and effectiveness in filtering liquids and gases. From food processing to water treatment, these filters serve multiple purposes and offer numerous benefits that make them an ideal choice for filtration needs.

One of the primary advantages of stainless steel filters is their exceptional resistance to corrosion. Unlike filters made from other materials, stainless steel can withstand harsh environments and aggressive chemicals without deteriorating. This property ensures a longer lifespan for the filters, reducing the frequency and cost of replacements. In industries such as oil and gas, where exposure to corrosive substances is common, stainless steel filters provide a reliable solution that enhances operational efficiency.

Another significant benefit of stainless steel filters is their ability to withstand high temperatures and pressures. This makes them suitable for applications in high-stress environments, such as pharmaceutical manufacturing and petrochemical processing. The robust nature of stainless steel allows these filters to maintain their structural integrity under extreme conditions, ensuring consistent performance and safety.

Stainless steel filters are also highly effective in removing contaminants from various substances. They can capture particles, dirt, rust, and algae from liquids, making them particularly valuable in water and wastewater treatment systems. By using stainless steel filters, facilities can ensure that they are providing clean and safe water, complying with health regulations, and protecting the environment.

stainless steel filters

Moreover, stainless steel filters are easy to clean and maintain. Many designs allow for backwashing, which can help prolong the life of the filter media and improve overall efficiency. This ease of maintenance is crucial in industries where downtime can lead to significant losses. Unlike disposable filters, stainless steel filters can be reused multiple times, making them a more sustainable option for environmentally conscious businesses.

In addition to industrial applications, stainless steel filters are increasingly used in residential and commercial settings. For instance, they are commonly found in coffee machines and brewing equipment to ensure that the brewed product is free from impurities and sediments. Their hygienic properties also make them a favorite in the food and beverage industry, where safety and cleanliness are paramount.

Furthermore, with advancements in technology, stainless steel filters are becoming more sophisticated. New designs such as wedge wire and perforated filters offer enhanced filtration capabilities while minimizing pressure drops. These innovations help optimize performance, making stainless steel filters suitable for a broader range of applications.

In conclusion, stainless steel filters provide a versatile and durable solution for filtration needs across various industries. Their corrosion resistance, ability to handle extreme conditions, effectiveness in contaminant removal, and ease of maintenance make them an indispensable tool in both industrial and residential applications. As industries continue to evolve and prioritize sustainability, the demand for stainless steel filters is likely to grow, further solidifying their place in the market. Investing in these filters not only enhances performance but also contributes to a more sustainable future.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025