-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

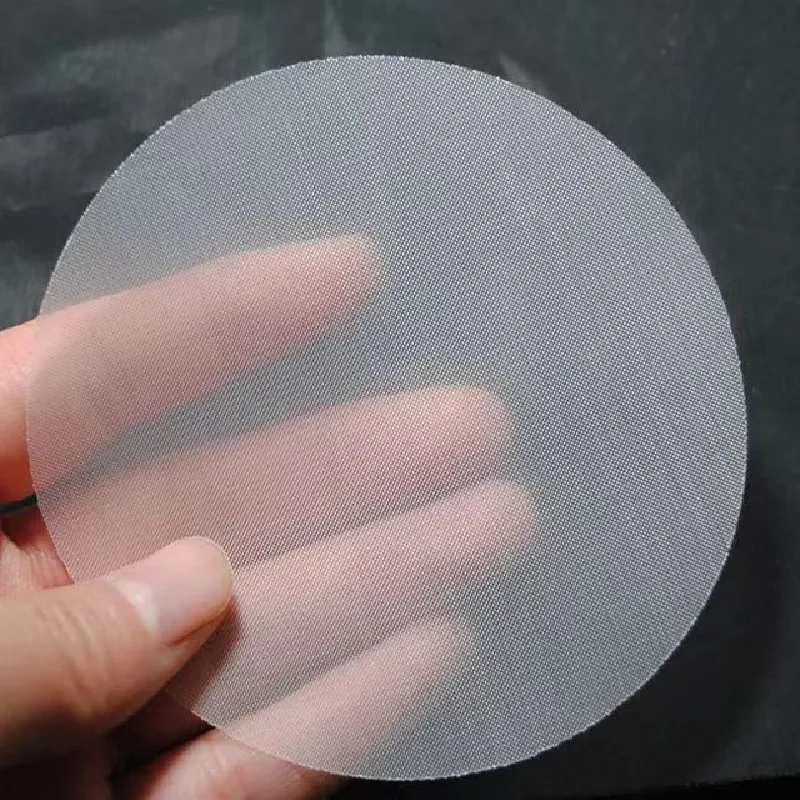

stainless steel filters strainers

Understanding Stainless Steel Filters and Strainers Essential Components for Efficient Filtration

In various industries, from food processing to pharmaceuticals and water treatment, maintaining cleanliness and quality is paramount. One of the most effective ways to ensure that systems operate smoothly and efficiently is by incorporating stainless steel filters and strainers. This article will explore the significance of these components, their applications, materials, and advantages.

The Basics of Filters and Strainers

Before diving into the specifics of stainless steel options, it is essential to understand the difference between filters and strainers. Both serve the primary purpose of removing unwanted particles from liquids or gases, but they operate differently and are designed for distinct applications.

Strainers typically remove larger debris from a liquid flow, ensuring that subsequent components, like pumps and valves, are protected from damage. On the other hand, filters are designed to capture finer particles, often in the micron or sub-micron range, which might otherwise contaminate the fluid or the equipment.

Why Choose Stainless Steel?

Stainless steel is the preferred material for filters and strainers due to its unique properties. Here are some reasons why

1. Corrosion Resistance Stainless steel has excellent resistance to corrosion and staining, making it ideal for various environments, including those with high humidity or exposure to aggressive chemicals.

2. Durability Steel filters and strainers are robust and can withstand significant pressures and temperatures, making them suitable for a wide range of industrial applications.

4. Extended Lifespan Compared to filters and strainers made from other materials, stainless steel options have a longer lifespan, resulting in lower replacement costs and reduced downtime in industrial processes.

stainless steel filters strainers

5. Sustainability Stainless steel is 100% recyclable, making it a more sustainable choice in an era where companies strive to reduce their environmental impact.

Applications of Stainless Steel Filters and Strainers

Stainless steel filters and strainers are versatile components with a wide array of applications across different industries

- Food and Beverage Industry In this sector, filters and strainers ensure that products are free from contaminants. They are used during various stages of processing, from water filtration to ingredient preparation.

- Water Treatment Municipal water systems employ stainless steel strainers to protect pumps and other equipment from debris in the water supply. Advanced filtration is also necessary to ensure consumer safety and regulatory compliance.

- Chemical and Petrochemical Industries Here, stainless steel filters and strainers play a crucial role in protecting sensitive equipment from particulates and sediment in corrosive environments.

- Pharmaceutical Industry In pharmaceutical manufacturing, cleanliness is critical. Stainless steel filters are utilized to ensure that liquids and gases are free from contaminants.

- HVAC Systems Filters in heating, ventilation, and air conditioning systems help maintain air quality by removing dust and particulate pollutants.

Conclusion

Stainless steel filters and strainers are critical components across various industries, providing effective solutions for maintaining fluid quality and protecting equipment. Their unique properties, including corrosion resistance, durability, and ease of cleaning, make them an ideal choice for demanding applications. As industries continue to prioritize efficiency and sustainability, the role of stainless steel filters and strainers in ensuring operational integrity remains indispensable.

Investing in high-quality stainless steel filtration solutions is an essential strategy for organizations looking to enhance their operational efficiency, reduce maintenance costs, and comply with safety regulations. As technology advances, we can expect to see further innovations in filtration systems, providing even more effective ways to remove contaminants and improve process reliability.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025