-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

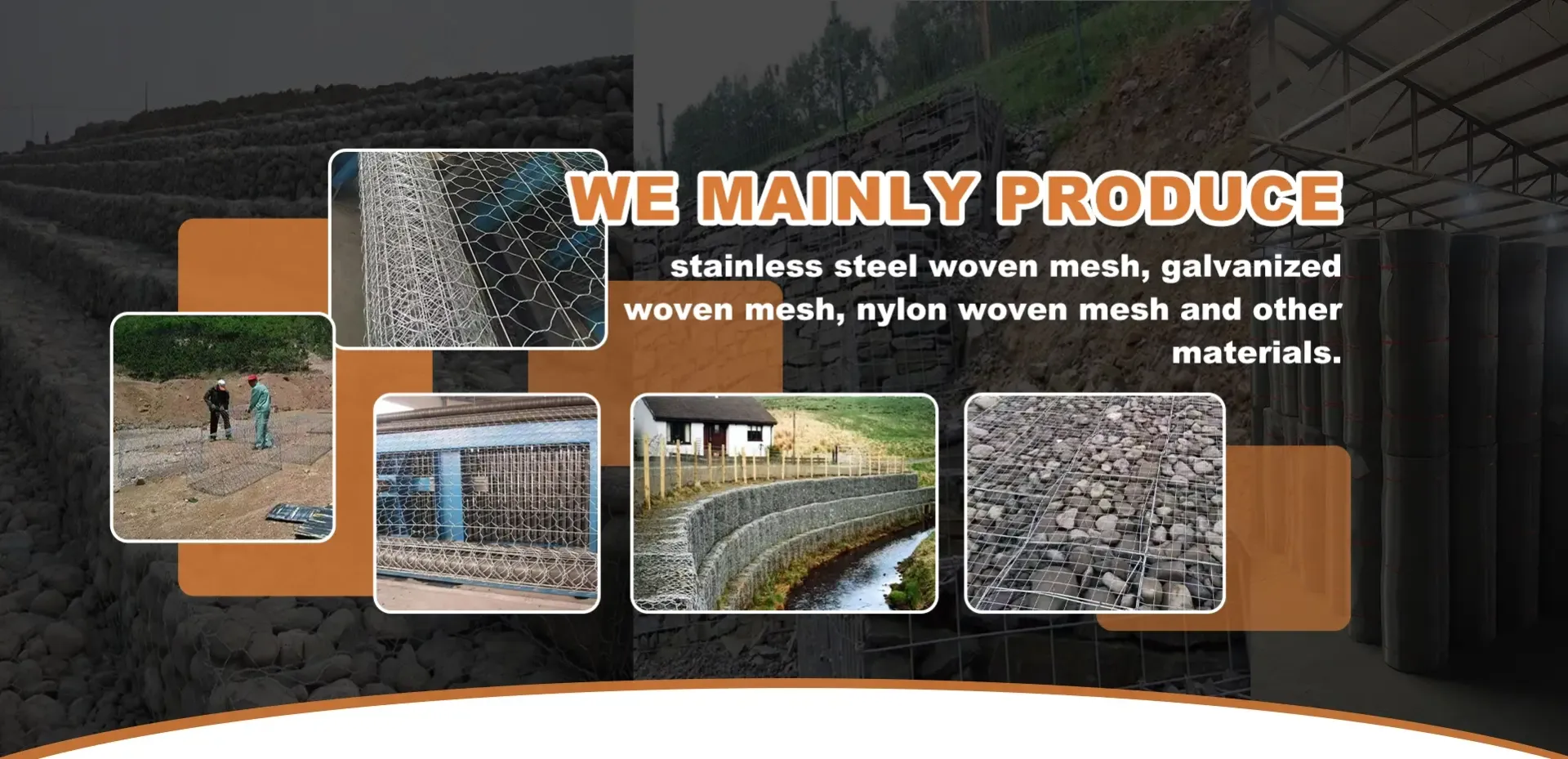

stainless steel mesh

Exploring Stainless Steel Mesh Versatility and Applications

Stainless steel mesh is a remarkable material that offers a combination of durability, resistance to corrosion, and versatility, making it an essential component in various industries. This woven mesh is produced from stainless steel wires, which can be treated to enhance specific properties. It is available in different grades, with the most common being 304 and 316 stainless steel, each suitable for various applications due to their unique properties.

One of the primary advantages of stainless steel mesh is its excellent resistance to corrosion. This characteristic is particularly important in environments where exposure to moisture, chemicals, and high temperatures is inevitable. For instance, the marine industry often uses stainless steel mesh for boat and ship construction as well as for various marine applications. The 316 grade, known for its high resistance to saltwater corrosion, is especially favored in such scenarios.

In addition to its corrosion resistance, stainless steel mesh is incredibly strong and durable. Its tensile strength makes it ideal for applications requiring a robust material that can withstand physical stress and strain. This quality is particularly beneficial in the construction and manufacturing industries, where stainless steel mesh is often used in safety screens, barriers, and reinforcement in concrete structures.

Stainless steel mesh is also known for its aesthetic appeal. Unlike other metal meshes, stainless steel retains a shiny, polished look that can enhance the appearance of various applications. This aesthetic property is evident in architectural designs, where stainless steel mesh is used in facades, railings, and as part of interior décor. It offers not only functional benefits but also contributes to a modern, sleek appearance that fits well in contemporary architectural styles.

stainless steel mesh

Another significant advantage of stainless steel mesh is its versatility. It can be manufactured in different weaves, openings, and gauges to meet specific requirements. For example, fine mesh is often employed in filtration applications, such as water treatment plants, food and beverage processing, and pharmaceutical industries, where it is essential to separate particles from liquids or gases. Conversely, coarser mesh might be used for applications that require a higher flow rate or a more rugged material, such as in mining or agriculture.

Moreover, stainless steel mesh is easy to clean and maintain, making it suitable for environments where hygiene is paramount, such as in food processing and healthcare settings. The non-porous surface of stainless steel allows for straightforward cleaning with detergents or disinfectants, ensuring that no bacteria or contaminants remain on the surface. This feature is crucial for maintaining compliance with health and safety regulations.

The durability and longevity of stainless steel mesh also translate to cost-effectiveness in the long term. While the initial investment may be higher compared to other materials, the extended lifespan and reduced need for replacements or repairs make it a financially sound choice. Businesses often prefer stainless steel mesh for its ability to withstand the test of time, ultimately resulting in lower operational costs.

In conclusion, stainless steel mesh is a multi-functional material that plays a vital role across various industries. Its corrosion resistance, durability, aesthetic appeal, versatility, and ease of maintenance make it an optimal choice for many applications. Whether used in architectural designs, industrial applications, or filtration systems, stainless steel mesh exhibits qualities that not only meet but often exceed the demands of modern industry. As we continue to innovate and explore new applications, the importance of stainless steel mesh remains paramount in ensuring safety, efficiency, and aesthetics in our daily lives.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025