-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

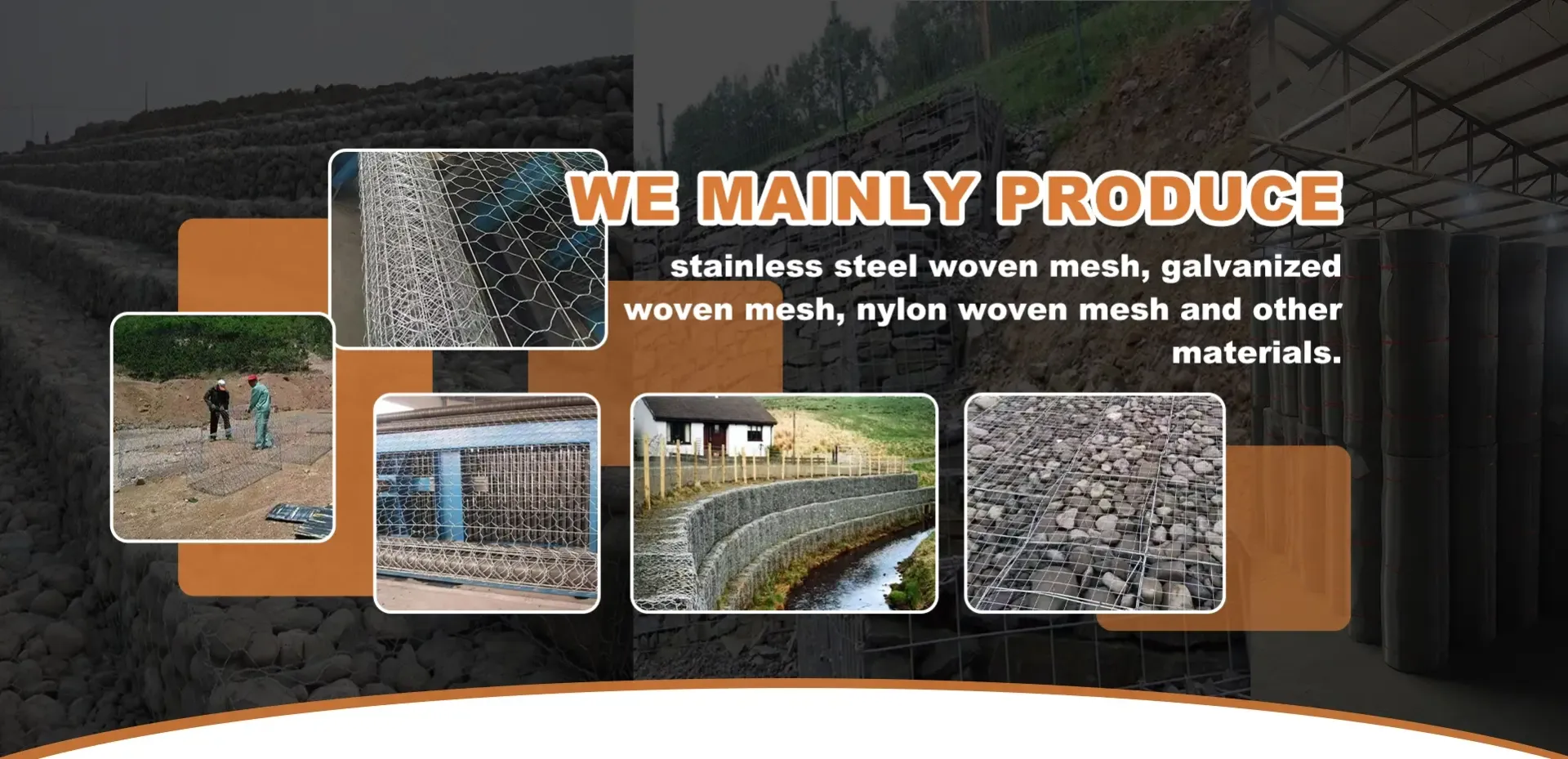

Durable and Versatile Uses of Stainless Steel Mesh in Various Applications

Understanding Stainless Steel Mesh A Versatile Material for Modern Applications

Stainless steel mesh is a remarkable material that has found its way into various applications across diverse industries. Renowned for its strength, durability, and resistance to corrosion, stainless steel mesh serves as a crucial component in numerous processes, ensuring efficiency and reliability. In this article, we will explore the properties, manufacturing processes, and applications of stainless steel mesh, emphasizing its significance in today’s industrial landscape.

Properties of Stainless Steel Mesh

Stainless steel mesh is primarily made from a mixture of iron, chromium, and other alloying elements, which collectively provide the material with its desired properties. One of the most notable characteristics of stainless steel is its resistance to rust and staining, attributed to the presence of chromium. This feature makes stainless steel mesh ideal for environments exposed to moisture, chemicals, and extreme temperatures.

In addition to corrosion resistance, stainless steel mesh possesses excellent tensile strength and durability. It is capable of withstanding considerable amounts of stress and strain, making it suitable for applications that require structural integrity and support. The mesh can be manufactured in various gauges and configurations, allowing for customization according to specific usage needs.

Manufacturing Process

The manufacturing of stainless steel mesh involves several key steps

. First, stainless steel wire is drawn to the desired gauge, ensuring that it meets specific standards for thickness and strength. Once the wire is ready, it is woven into a mesh pattern, commonly done using a weaving process that can produce different mesh types, such as plain weave, twill weave, and Dutch weave.The weaving technique chosen depends on the intended application of the mesh. For instance, a plain weave is commonly used for general applications, while a Dutch weave offers higher filtration capabilities, making it suitable for more demanding tasks. After weaving, the mesh may undergo additional treatments, such as annealing, to improve its properties and enhance its overall performance.

Applications of Stainless Steel Mesh

stainless steel mesh

Stainless steel mesh finds applications across a wide range of industries, including construction, food and beverage processing, pharmaceuticals, and environmental engineering, to name a few. Here are some prominent applications

1. Filtration One of the most common uses of stainless steel mesh is in filtration systems. Its fine weave allows for the efficient separation of liquids and solids, making it ideal for water treatment plants, oil refineries, and chemical processing facilities. Stainless steel mesh is used in various filtration products, including strainers, filters, and sieves.

2. Architecture and Design In the field of architecture, stainless steel mesh is increasingly used for aesthetic and functional purposes. It can be employed as decorative facades, safety barriers, or even sunshades, blending aesthetics with structural utility. Its transparency and strength make it a popular choice for modern design elements.

3. Construction In construction, stainless steel mesh serves as reinforcement in concrete, providing additional strength and stability. It can also be used in fencing, walls, and other structural applications, ensuring long-lasting performance even in harsh environments.

4. Food Processing The food industry benefits greatly from stainless steel mesh due to its hygienic properties. It is commonly used in equipment such as conveyor belts, screens, and baskets for food preparation and processing. Its resistance to corrosion ensures that it maintains a clean environment for food handling.

5. Aerospace and Automotive In the aerospace and automotive sectors, stainless steel mesh is utilized for various applications, including sound absorption, filtration, and protection against debris. The lightweight nature of stainless steel combined with its strength makes it an ideal choice for components that require durability without added weight.

Conclusion

Stainless steel mesh is an invaluable material that plays a significant role in numerous industries. With its unique properties and diverse applications, it continues to be a preferred choice for engineers, architects, and designers alike. As advancements in technology and manufacturing processes evolve, the applications of stainless steel mesh will only expand further, reaffirming its place as a cornerstone of modern engineering and design. Understanding its properties and applications is essential for anyone looking to leverage the benefits of this versatile material in their projects.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025