-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

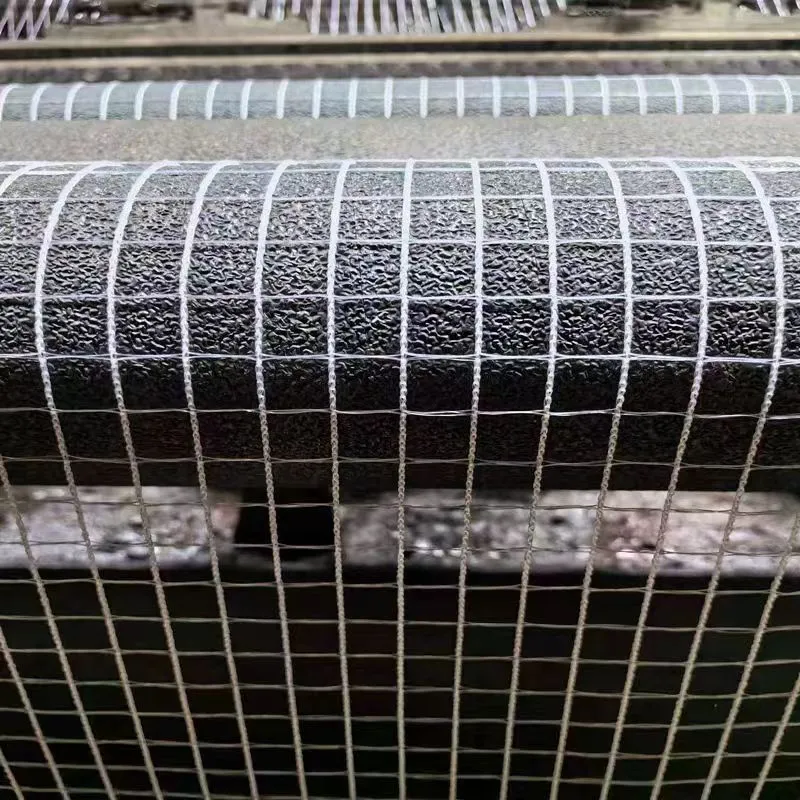

Durable Stainless Steel Mesh Filters for Efficient Grease Filtration

Understanding Stainless Steel Mesh Grease Filters Key Features and Benefits

Stainless steel mesh grease filters play a vital role in commercial kitchens and various industries that require effective air filtration. As culinary establishments strive to create a safe and clean cooking environment, the importance of proper grease filtration cannot be overstated. This article explores the functionality, advantages, and maintenance of stainless steel mesh grease filters, highlighting why they are essential in any kitchen setup.

What Are Stainless Steel Mesh Grease Filters?

Stainless steel mesh grease filters are designed to trap and collect grease particles and other contaminants from the air. These filters are typically used in range hoods and exhaust systems to prevent grease buildup and ensure optimal airflow. Constructed from stainless steel, these filters offer durability and resistance to corrosion, making them an ideal choice for high-performance environments. The mesh design allows for excellent air passage while effectively capturing grease droplets.

Key Features

1. Material Composition The use of stainless steel is a defining feature of these filters. Stainless steel is not only strong and durable but also resists rust and corrosion, prolonging the life of the filter. This material can withstand the heat and humidity often present in kitchen environments.

2. Mesh Design The mesh structure is essential for effective grease filtration. The interwoven stainless steel strands create a labyrinth that captures grease while allowing air to flow freely. This design prevents clogging, ensuring consistent suction performance and reduced energy consumption.

3. Washable and Reusable Unlike traditional paper filters that require frequent replacement, stainless steel mesh grease filters can be washed and reused. This not only saves on replacement costs but also makes them a more environmentally friendly option.

4. Customizable Sizes Grease filters come in various sizes and configurations to fit different kitchen setups. This versatility allows for easy integration into existing exhaust systems, making it simple to upgrade or replace outdated filters.

Benefits of Stainless Steel Mesh Grease Filters

stainless steel mesh grease filters

1. Enhanced Safety An efficient grease filtration system minimizes the risk of grease fires in commercial kitchens. By trapping grease before it can accumulate in the exhaust ducts, these filters enhance overall safety.

2. Improved Air Quality By capturing airborne contaminants, stainless steel mesh filters contribute to a healthier work environment. This ensures that kitchen staff breathe cleaner air, which can improve productivity and reduce health-related issues.

3. Cost Efficiency The ability to clean and reuse these filters reduces ongoing operational costs. Additionally, effective grease filtration optimizes kitchen equipment performance, potentially extending its lifespan and reducing maintenance costs.

4. Regulatory Compliance Many health and safety regulations require commercial kitchens to utilize effective grease filters. Using stainless steel mesh filters can help ensure compliance, avoiding potential fines and penalties.

5. Ease of Maintenance Maintaining stainless steel grease filters is straightforward. Most can be easily removed, cleaned with soap and warm water or in a dishwasher, and re-installed, keeping downtime to a minimum.

Maintenance Tips

To ensure optimal performance, regular maintenance of stainless steel mesh grease filters is essential. Here are a few tips

- Frequency of Cleaning Depending on kitchen use, it is advisable to clean the filters every few weeks or more frequently in high-volume environments. - Check for Damage Inspect the filters regularly for any signs of wear, such as bent or broken mesh. Damaged filters may need to be replaced to ensure safety and effectiveness. - Follow Manufacturer Guidelines Different models may have specific cleaning and maintenance instructions, so always refer to the manufacturer’s recommendations.

Conclusion

Stainless steel mesh grease filters are indispensable in ensuring a safe and efficient kitchen environment. Their combination of durable materials, efficient design, and ease of maintenance make them a preferred choice for restaurant and kitchen operations. By investing in these filters, businesses can not only comply with safety regulations but also enhance air quality, reduce maintenance costs, and ultimately create a better cooking atmosphere for staff. As kitchens continue to evolve, stainless steel mesh grease filters will remain a critical component of culinary safety and operational excellence.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025