-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

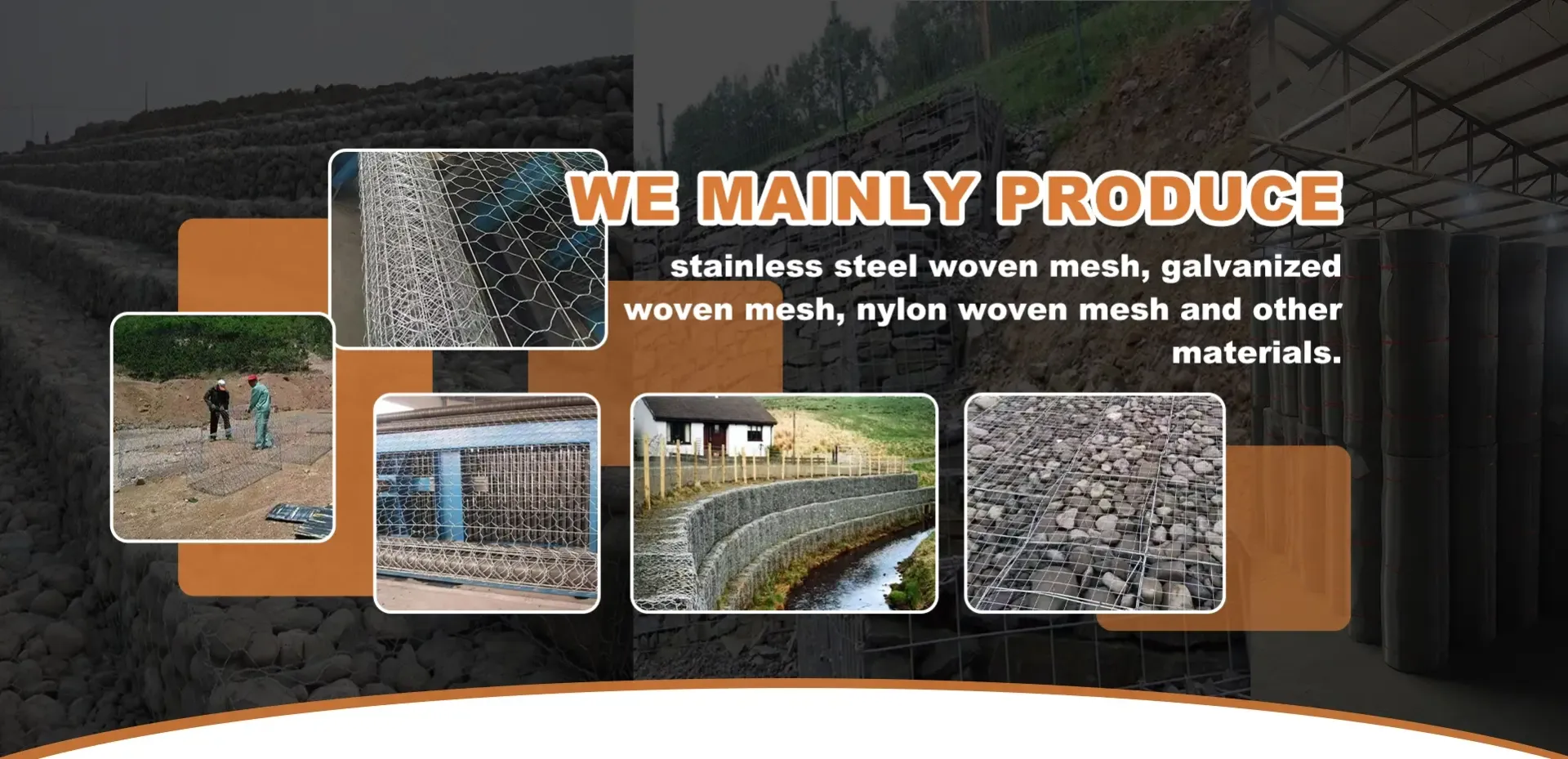

stainless steel mesh manufacturers

The Rise of Stainless Steel Mesh Manufacturers An Overview

In recent years, stainless steel mesh has gained considerable momentum in various industries due to its exceptional properties and versatile applications. As a result, the market for stainless steel mesh manufacturers has seen significant growth. This article explores the importance of stainless steel mesh, the benefits of using it, and the factors contributing to the rise of manufacturers in this sector.

What is Stainless Steel Mesh?

Stainless steel mesh is a type of wire cloth made from stainless steel that is woven into a grid pattern. This durable material is available in different grades and specifications, making it adaptable to a wide range of uses. Its properties include corrosion resistance, strength, and longevity, making it an ideal choice for industries that require high-performance materials.

Applications of Stainless Steel Mesh

Stainless steel mesh is widely used across various sectors

1. Construction and Architecture Used in screens, facades, and even fencing, stainless steel mesh provides aesthetic appeal along with structural integrity. It can be used to create intricate designs while maintaining safety standards.

2. Food and Beverage In the food industry, stainless steel mesh is utilized in filters and sieves due to its hygienic properties and ease of cleaning. It helps in maintaining the quality and purity of products.

3. Automotive In automotive applications, stainless steel mesh is employed in various components for filtration systems, ensuring better performance and longevity of vehicles.

4. Pharmaceuticals The pharmaceutical sector uses stainless steel mesh for products that require sterility and reliability. It is often involved in the filtration processes, pharmaceutical packaging, and as a support structure for products.

5. Industrial Applications Numerous industries, including petroleum, chemical processing, and mining, use stainless steel mesh for filters, strainers, and protective screens. Its ability to withstand high temperatures and corrosive conditions makes it invaluable.

Advantages of Stainless Steel Mesh

stainless steel mesh manufacturers

The increasing demand for stainless steel mesh can be attributed to several advantages

- Corrosion Resistance Stainless steel is inherently resistant to rust and corrosion, ensuring that products will last longer and require less maintenance.

- Strength and Durability Stainless steel mesh can endure harsh environmental conditions and maintain its structural integrity over time.

- Variety of Mesh Sizes Manufacturers can produce stainless steel mesh in various wire diameters and mesh sizes, providing flexibility for specific applications.

- Recyclability Being made from stainless steel, stainless steel mesh is recyclable, making it an environmentally friendly choice.

- Cost-Effectiveness Although the upfront cost may be higher compared to other materials, the longevity and reduced maintenance costs associated with stainless steel mesh often result in better value over time.

The Manufacturers' Landscape

The growth of stainless steel mesh manufacturers is driven by the increasing demand in both traditional markets and emerging markets. Manufacturers are investing in advanced technologies and innovative designs to meet the evolving needs of consumers. Many companies are focusing on enhancing their production capacities, streamlining processes, and ensuring high-quality standards.

Furthermore, globalization and the rise of e-commerce have allowed manufacturers to reach a broader customer base, providing more opportunities for growth. The competition in the market has also led to improved service delivery, better products, and more competitive pricing.

Conclusion

The stainless steel mesh industry is poised for continued growth as businesses and consumers recognize the myriad benefits of this versatile material. Manufacturers are responding to the demand by innovating and expanding their offerings, positioning themselves to capitalize on emerging opportunities. As various sectors continue to incorporate stainless steel mesh in their operations, the landscape of stainless steel mesh manufacturers will likely evolve, bringing even more advancements to the market. This sector's adaptability and commitment to quality will play a crucial role in shaping the future of materials in industrial and consumer applications alike.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025