-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

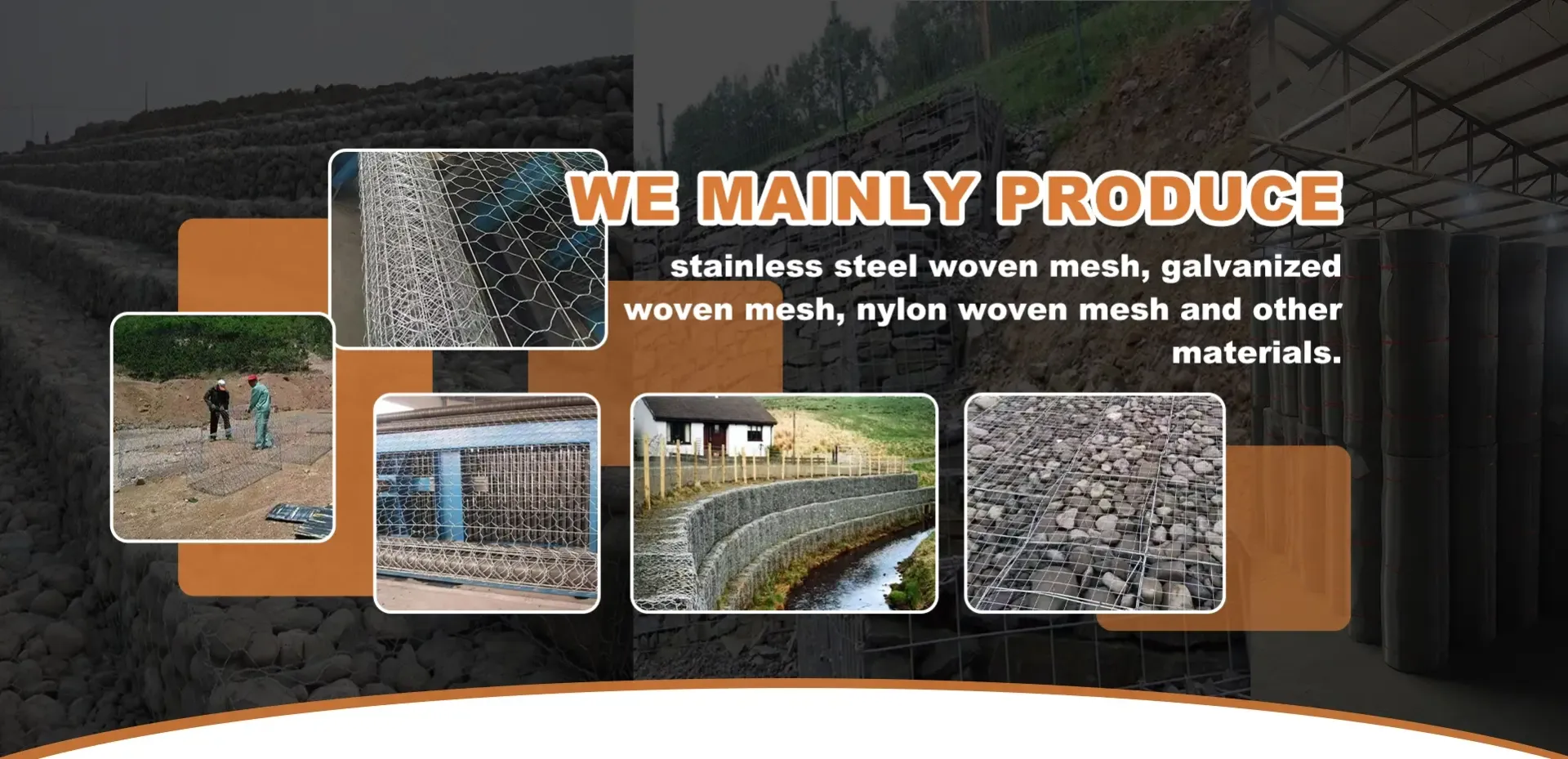

Leading Manufacturers of Stainless Steel Mesh for Diverse Applications

The Role of Stainless Steel Mesh Manufacturers in Various Industries

Stainless steel mesh is a vital component in numerous applications across various industries due to its durability, resistance to corrosion, and structural integrity. This versatile product is used in filtration, safety, construction, automotive, and many more sectors. The role of stainless steel mesh manufacturers is crucial as they supply the material that meets diverse industrial needs while ensuring high standards of quality and performance.

Understanding Stainless Steel Mesh

Stainless steel mesh is made from stainless steel wires that are woven together to form a grid pattern. The mesh is available in various shapes, sizes, and grades, which can be customized according to specific requirements. The most common grades used in the production of stainless steel mesh include 304 and 316, with varying properties that determine their suitability for different applications.

The primary advantages of stainless steel mesh include its resistance to rust and corrosion, high tensile strength, and ability to withstand extreme temperatures. These characteristics make it ideal for use in challenging environments where other materials would fail.

Applications of Stainless Steel Mesh

1. Filtration One of the most common applications of stainless steel mesh is in the filtration industry. It is used in water treatment plants, chemical processing, food and beverage industries, and pharmaceuticals to filter out impurities and ensure the purity of products. The precision of stainless steel mesh allows it to capture particulate matter effectively and can be designed to meet specific filtration requirements.

2. Safety and Security Stainless steel mesh plays an important role in safety applications. It is used in the construction of safety barriers, window screens, and security fencing. Its strength and durability provide protection against intrusion while allowing visibility and airflow. Additionally, stainless steel mesh can be used in handrail systems and staircases, providing both safety and aesthetic appeal.

stainless steel mesh manufacturers

3. Architectural Applications In modern architecture, stainless steel mesh is increasingly used for decorative elements. Architectural mesh can be used in facades, balustrades, and sun shades, offering a combination of functionality and design. Manufacturers often work with architects to create unique and visually appealing structures that also meet safety codes.

4. Automotive Industry Stainless steel mesh is also utilized in the automotive sector, especially in the manufacturing of filters and screens for engines and exhaust systems. Its ability to withstand high temperatures and corrosive environments makes it an excellent choice for components that require longevity and reliability.

5. Food Processing The food and beverage industry demands materials that not only provide functionality but also comply with health regulations. Stainless steel mesh is widely used in food processing equipment, including strainers and conveyors, due to its non-reactive properties and ease of cleaning.

Challenges Faced by Manufacturers

While stainless steel mesh is in high demand, manufacturers face several challenges that can impact production quality and delivery times. Fluctuating raw material prices for stainless steel can affect manufacturing costs. Additionally, meeting the stringent regulatory requirements in industries like food processing and pharmaceuticals necessitates a commitment to quality assurance and control processes.

Moreover, technological advancements have led to an increased demand for customized stainless steel mesh products. Manufacturers must invest in modern machinery and skilled artisans to meet these evolving needs while maintaining product quality.

Conclusion

Stainless steel mesh manufacturers play an instrumental role in supplying this vital material to various industries. Their ability to produce high-quality, durable, and customizable products ensures that they meet the specific needs of their customers. As industries continue to evolve and technology advances, the importance of stainless steel mesh will undoubtedly grow, highlighting the essential contributions of manufacturers in this field. By embracing innovation and maintaining strict quality control, stainless steel mesh manufacturers can continue to thrive in a competitive market, providing solutions that meet the high standards required for diverse applications.

-

Why Construction Steel Mesh is the Backbone of Modern InfrastructureNewsJun.27,2025

-

The Ultimate Solution for Versatile Industrial and Consumer ApplicationsNewsJun.27,2025

-

Smart Breeding Starts Here: The Ideal Breeder Net for GuppiesNewsJun.27,2025

-

Maximize Your Harvest with Smart NetNewsJun.27,2025

-

High-Performance Steel Mesh Solutions for Modern IndustryNewsJun.27,2025

-

Durable Solutions for Modern Agriculture and LandscapingNewsJun.27,2025