-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

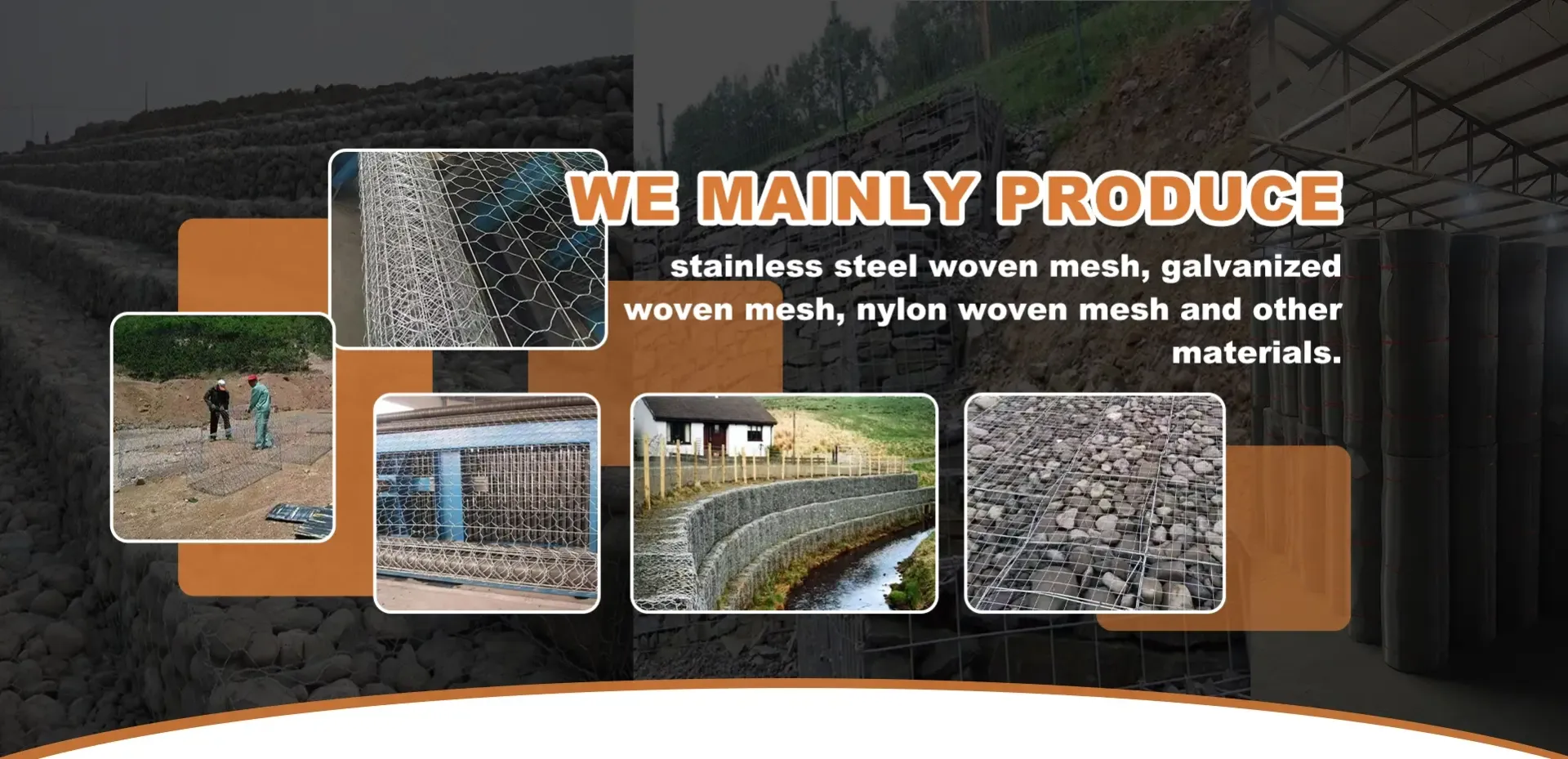

Stainless Steel Mesh Suppliers for Quality Industrial Applications and Custom Solutions

The Rise of Stainless Steel Mesh Manufacturers A Comprehensive Overview

Stainless steel mesh has become an integral component in various industries, attributed to its exceptional durability, corrosion resistance, and versatility. The demand for high-quality stainless steel mesh has surged, leading to the emergence of numerous manufacturers in the global market. This article delves into the intricacies of stainless steel mesh manufacturing, exploring its applications, benefits, and the factors influencing the industry's growth.

Understanding Stainless Steel Mesh

Stainless steel mesh is composed of interwoven stainless steel wire, creating a grid-like structure that can be used for filtration, reinforcement, and protection purposes. The alloy used in stainless steel provides an advantage—resistance to rust and stains, making it a preferred choice in challenging environments. Manufacturers offer various types of stainless steel mesh, including woven wire mesh, welded wire mesh, and expanded metal mesh, each suited for specific applications.

Applications of Stainless Steel Mesh

The applications of stainless steel mesh are vast and varied. In the construction industry, it is used for reinforcement in concrete structures, ensuring stability and longevity. In food processing, stainless steel mesh serves as a sieve for separating materials and ensuring that products remain free of contaminants. The pharmaceutical industry relies on stainless steel mesh for filtration and sterilization processes due to its high-level cleanliness and safety standards.

Moreover, the automotive and aerospace sectors utilize stainless steel mesh for various purposes, including sound insulation and as filters. The mesh's ability to withstand extreme temperatures and harsh chemicals makes it essential in these fields. Additionally, the civil engineering sector employs stainless steel mesh in the construction of bridges and tunnels, where durability is paramount.

Benefits of Stainless Steel Mesh

stainless steel mesh manufacturers

Manufacturers and consumers alike appreciate several advantages of stainless steel mesh

. First and foremost, its corrosion resistance ensures a longer lifespan, reducing the need for frequent replacements. This quality not only contributes to cost-effectiveness but also minimizes waste, aligning with modern sustainability efforts.Furthermore, stainless steel mesh is non-reactive, which is crucial in industries like food and pharmaceuticals, where contamination is a significant concern. The ease of cleaning and maintaining stainless steel mesh also enhances its appeal across various sectors.

In terms of aesthetics, manufacturers often produce stainless steel mesh in various finishes and designs, making it suitable for architectural features while providing practical benefits. This dual functionality has led to a rising trend in its use in interior design and modern architecture.

Factors Influencing the Growth of Stainless Steel Mesh Manufacturers

Several factors are driving the growth of stainless steel mesh manufacturers. The increasing demand for filtration solutions in water treatment facilities, the growing construction sector, and rising investments in infrastructure projects are significant contributors. Additionally, the push towards sustainability and improved safety regulations across industries emphasizes the need for robust materials such as stainless steel mesh.

Technological advancements in manufacturing processes, such as precision welding and automated weaving techniques, enable manufacturers to produce high-quality mesh more efficiently. As the market becomes increasingly competitive, manufacturers are investing in research and development to innovate and improve product offerings.

Conclusion

As industries continue to evolve and demand for reliable and durable materials increases, stainless steel mesh manufacturers are positioned at the forefront of this trend. The versatility, strength, and aesthetic appeal of stainless steel mesh make it an essential component across multiple sectors. With ongoing advancements in technology and growing awareness of the environmental benefits of using durable materials, the future of stainless steel mesh manufacturing appears promising, catering to an ever-expanding range of applications and industries.

-

The Sunshade Net Can Block Ultraviolet RaysNewsAug.11,2025

-

Main Application and Technology of Nylon ScreenNewsAug.11,2025

-

Green Anti UV Sunshade Net: The Perfect Combination of Ecological Friendliness and Practical PerformanceNewsAug.11,2025

-

Explore the Sunshade NetNewsAug.11,2025

-

Application and Development of Nylon Screen in Fuel Processing and TreatmentNewsAug.11,2025

-

Application and Advantages of Nylon Screen for AquacultureNewsAug.11,2025