-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Stainless Steel Mesh Screens for Various Applications and Industries

The Versatility and Applications of Stainless Steel Mesh Screens

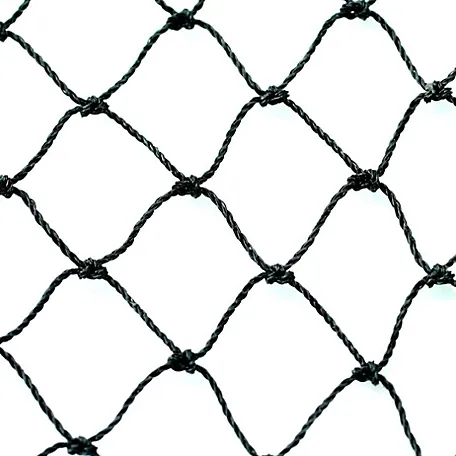

Stainless steel mesh screens have become indispensable in various industries due to their unique properties and versatility. Made from high-quality stainless steel wire, these screens are designed to withstand harsh environmental conditions while providing excellent performance. The combination of durability, corrosion resistance, and aesthetic appeal makes stainless steel mesh screens a popular choice for a wide range of applications.

What is Stainless Steel Mesh?

Stainless steel mesh is a fabric-like material made from woven or welded stainless steel wires. It can be produced in various sizes and configurations, such as mesh count, wire diameter, and weave type, allowing for customization according to specific needs. The mesh can be categorized into two primary types woven mesh, which is created by interlacing wires, and welded mesh, which consists of wires that are welded at their intersections. Each type has distinct attributes making it suitable for different applications.

Advantages of Stainless Steel Mesh Screens

One of the most significant advantages of stainless steel mesh screens is their resistance to corrosion and rust. Unlike other metals, stainless steel maintains its integrity in the face of moisture, chemicals, and extreme environmental conditions. This characteristic makes it ideal for applications in the food processing, pharmaceutical, and chemical industries, where hygienic conditions are paramount. Additionally, stainless steel screens are easy to clean and maintain, enhancing their longevity.

Stainless steel mesh also possesses remarkable strength and durability. The inherent strength of stainless steel ensures that the mesh can withstand considerable tension and pressure, making it suitable for filtration and separation processes. Depending on the wire gauge and mesh count, these screens can be engineered to filter particles of various sizes, from coarse debris to fine powders.

stainless steel mesh screen

Further, stainless steel mesh screens provide excellent transparency and visibility, allowing for good light transmission while still acting as a barrier

. This quality is particularly useful in architectural applications where aesthetic appeal and functionality must coexist.Applications of Stainless Steel Mesh Screens

The applications of stainless steel mesh are extensive. In the construction and architectural industry, stainless steel mesh is often used for decorative facades, safety barriers, and sunscreens. Its ability to offer both privacy and light filtration makes it a favored choice for modern building designs.

In the industrial sector, stainless steel mesh screens are used in filtration systems across various industries, including water treatment, food processing, and petrochemical. They effectively filter out contaminants while allowing the passage of fluids and gases, ensuring operational efficiency and product quality. Additionally, stainless steel meshes are vital in sandblasting and shot blasting processes, protecting equipment while ensuring even surface finishes.

In agriculture, stainless steel mesh screens are utilized in irrigation systems, protecting pumps and filtration systems from debris and contaminants. They also find applications in beekeeping, where mesh screens are used in hive covers to provide ventilation while keeping pests at bay.

Conclusion

The versatility of stainless steel mesh screens cannot be overstated. Their unique combination of durability, corrosion resistance, and aesthetic appeal makes them an ideal choice for numerous applications across various industries. As technology continues to evolve, the development of more advanced stainless steel mesh products is likely to enhance their functionality further and expand their use. Whether in construction, filtration, agriculture, or any other sector, stainless steel mesh screens have established themselves as a reliable solution for a myriad of challenges. Understanding their properties and applications can help industries harness their full potential, leading to more efficient processes and enhanced product quality.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025