-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 19, 2025 04:10

Back to list

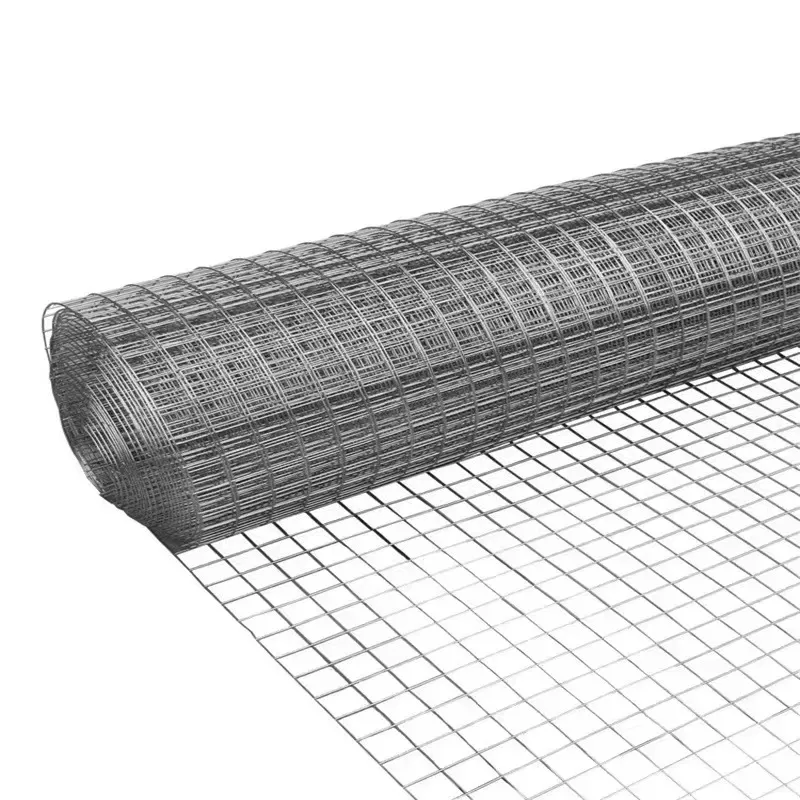

24 mesh Anti-insect netting

Stainless steel netting, a robust and versatile product, has found widespread applications across various industries, offering unique advantages that make it indispensable. This article delves into its myriad uses, production techniques, and the unparalleled benefits it brings to the table, underlining its importance in modern industrial applications.

Furthermore, its application extends to public infrastructure. Cities employ stainless steel netting in bridges, stairways, and public transportation to ensure safety and longevity. Its strength ensures stability, while its resistance to vandalism and weather elements guarantees minimal upkeep. This characteristic makes it an economically viable option for government projects with tight budgets and high safety standards. During the manufacturing process, stainless steel netting undergoes rigorous quality checks to ensure optimum performance. The choice of stainless steel grade, the thickness of wires, and the weaving or welding technique are all carefully considered to meet specific industry needs. With technological advancements, new manufacturing processes have enhanced the quality even further, ensuring that stainless steel netting remains at the forefront of safety and durability. From an environmental perspective, stainless steel netting is a sustainable choice. As a material, stainless steel is completely recyclable, reducing its carbon footprint. Its longevity also means fewer replacements and less waste, driving the initiative towards sustainable development. Companies and industries focused on reducing their environmental impact increasingly prefer stainless steel netting to support their green initiatives. In terms of trustworthiness and expertise, it is essential to source stainless steel netting from reputable manufacturers. Trusted suppliers provide certification and documentation, assuring customers of the material's authenticity and quality. Engaging with experienced providers ensures the product meets specific industrial standards, guaranteeing safety, reliability, and customer satisfaction in its application. In conclusion, stainless steel netting stands out as a multifaceted material that merges strength with versatility. Its extensive usage across multiple industries showcases its indispensable role in modern applications, offering benefits that few materials can match. Trust in stainless steel netting is well-founded, given its proven track record of performance and reliability. As industries evolve and demand more from their materials, stainless steel netting continues to meet and exceed expectations, establishing itself as a cornerstone in industrial innovation and environmental sustainability.

Furthermore, its application extends to public infrastructure. Cities employ stainless steel netting in bridges, stairways, and public transportation to ensure safety and longevity. Its strength ensures stability, while its resistance to vandalism and weather elements guarantees minimal upkeep. This characteristic makes it an economically viable option for government projects with tight budgets and high safety standards. During the manufacturing process, stainless steel netting undergoes rigorous quality checks to ensure optimum performance. The choice of stainless steel grade, the thickness of wires, and the weaving or welding technique are all carefully considered to meet specific industry needs. With technological advancements, new manufacturing processes have enhanced the quality even further, ensuring that stainless steel netting remains at the forefront of safety and durability. From an environmental perspective, stainless steel netting is a sustainable choice. As a material, stainless steel is completely recyclable, reducing its carbon footprint. Its longevity also means fewer replacements and less waste, driving the initiative towards sustainable development. Companies and industries focused on reducing their environmental impact increasingly prefer stainless steel netting to support their green initiatives. In terms of trustworthiness and expertise, it is essential to source stainless steel netting from reputable manufacturers. Trusted suppliers provide certification and documentation, assuring customers of the material's authenticity and quality. Engaging with experienced providers ensures the product meets specific industrial standards, guaranteeing safety, reliability, and customer satisfaction in its application. In conclusion, stainless steel netting stands out as a multifaceted material that merges strength with versatility. Its extensive usage across multiple industries showcases its indispensable role in modern applications, offering benefits that few materials can match. Trust in stainless steel netting is well-founded, given its proven track record of performance and reliability. As industries evolve and demand more from their materials, stainless steel netting continues to meet and exceed expectations, establishing itself as a cornerstone in industrial innovation and environmental sustainability.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025