-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

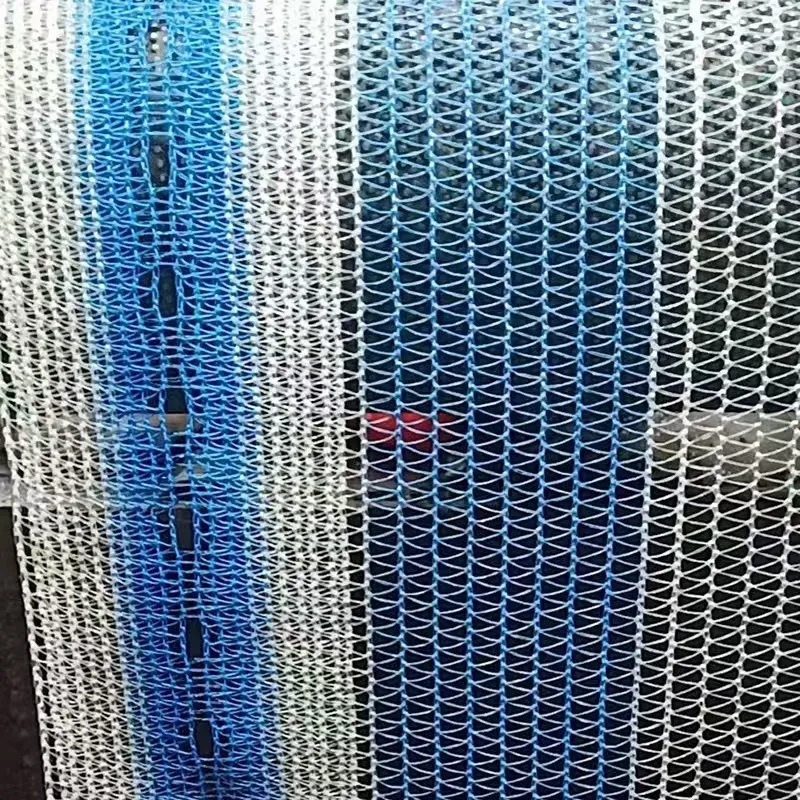

Durable Stainless Steel Wire Mesh for Versatile Industrial Applications

The Versatile Applications of Stainless Steel Wire Grid

Stainless steel wire grids are an essential component in various industries due to their durability, strength, and resistance to corrosion. Made from high-quality stainless steel, these grids have gained popularity in numerous applications ranging from construction to arts and crafts. This article delves into the characteristics, manufacturing processes, and diverse applications of stainless steel wire grids, shedding light on why they have become an integral part of modern infrastructure and design.

Characteristics of Stainless Steel Wire Grids

The most notable feature of stainless steel wire grids is their corrosion resistance. Stainless steel, as the name suggests, is an alloy that contains chromium, which reacts with oxygen in the environment to form a passive layer of chromium oxide. This layer protects the underlying metal from rust and degradation, making it ideal for outdoor and marine applications where exposure to moisture and harsh conditions is a concern. Furthermore, stainless steel wire grids offer excellent tensile strength, allowing them to bear significant loads and resist deformation under stress.

Moreover, they are easy to clean and maintain, which contributes to their longevity. Their aesthetic appeal cannot be overlooked either; the sleek, shiny finish of stainless steel provides a modern touch to any application. When it comes to customization, these grids can be manufactured in various sizes, wire diameters, and mesh patterns, catering to specific project requirements.

Manufacturing Process

The manufacturing of stainless steel wire grids involves several stages, starting with the selection of high-grade stainless steel wire. This wire is then processed through a series of drawing, stretching, and welding techniques to create the desired grid structure. The welding process is crucial as it ensures that the wires are securely bonded, enhancing the grid's strength and stability.

After forming the grid, further treatments such as polishing and passivation may be applied to improve the surface finish and further boost corrosion resistance. Quality control measures are also implemented to ensure that the final product meets industry standards. This process not only ensures durability but also makes stainless steel wire grids highly reliable for various applications.

Diverse Applications

stainless steel wire grid

Stainless steel wire grids are widely used across multiple sectors

1. Construction and Architecture In construction, stainless steel wire grids are often used as reinforcement materials in concrete applications. They provide additional strength and stability to structures, making them ideal for use in floors, walls, and ceilings. Additionally, architects are increasingly using these grids for decorative purposes in facades and interior design, where they serve as functional yet visually appealing elements.

2. Food Industry The food industry benefits significantly from stainless steel wire grids due to their hygienic properties. They are commonly used in food processing plants and restaurants for shelving units, racks, and conveyor systems. Stainless steel is easy to sanitize, making it suitable for handling food products.

3. Agriculture In agriculture, stainless steel wire grids are utilized in various forms, such as fencing and cages for livestock. Their durability and resistance to weather elements ensure longevity, reducing the need for frequent replacements.

4. Arts and Crafts Artists and DIY enthusiasts have also found unique uses for stainless steel wire grids. They can be manipulated into sculptures, decorative wall art, or structural components in modern art projects. The versatility of wire grids allows for creative expression while benefiting from the material's strength.

5. Industrial Uses Stainless steel wire grids are commonly employed in filtration systems, where they can effectively filter out particles while allowing for the free flow of liquids or gases. Their strength and resistance to various chemicals make them suitable for harsh industrial environments.

Conclusion

Stainless steel wire grids represent a unique intersection of strength, versatility, and aesthetic appeal. Their comprehensive range of applications across different industries not only highlights their utility but also underscores the importance of reliable materials in the modern world. As technology advances and new manufacturing techniques emerge, the role of stainless steel wire grids in enhancing both functional and artistic projects is likely to expand even further, solidifying their status as a cornerstone in various fields.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025