-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Stainless Steel Wire and Mesh Applications for Strength and Durability in Various Industries

The Versatility of Stainless Steel Wire and Mesh

Stainless steel wire and mesh are integral components in a wide range of applications, combining strength, durability, and resistance to corrosion. These materials have garnered significant attention across various industries due to their impressive properties, making them ideal for both structural and decorative purposes.

Composition and Properties

Stainless steel is an alloy composed primarily of iron, along with a minimum of 10.5% chromium content. This unique combination of materials significantly enhances its resistance to oxidation and rust, giving stainless steel its renowned durability. The addition of other elements, such as nickel and molybdenum, further improves its mechanical properties and resistance to certain environments, including extreme temperatures and corrosive conditions.

Stainless steel wire comes in various gauges, allowing for flexibility in application. It can be braided, twisted, or woven into different configurations to create wire ropes, cables, and mesh. The strength-to-weight ratio of stainless steel wire is exceptionally high, making it suitable for applications ranging from construction to marine industries. The inherent ductility and malleability of stainless steel also allow it to be easily formed into intricate shapes without losing its structural integrity.

Applications

One of the most common uses for stainless steel wire is in architectural design. Stainless steel mesh is often employed in building facades, railings, and interior elements, providing both aesthetic appeal and functional safety. Its sleek, modern look complements a variety of design styles while ensuring longevity and minimal maintenance efforts.

stainless steel wire & mesh

In the industrial sector, stainless steel wire and mesh are essential for filtration and separation processes. They are used in water treatment facilities, food processing, pharmaceuticals, and chemical plants to create filters that withstand harsh environments. The fine mesh allows for efficient separation of solids from liquids without compromising the integrity of the final product.

Moreover, stainless steel wire is frequently used in the construction industry for reinforcing concrete and providing structural support. Its strength helps to improve the tensile strength of concrete structures, enhancing their load-bearing capacity. This makes stainless steel wire an invaluable resource for engineers and architects looking to create safe, durable buildings.

Advantages

The benefits of using stainless steel wire and mesh extend beyond property and performance. This material is highly resistant to corrosion, making it suitable for use in diverse environments, from coastal areas with high saline exposure to chemical processing plants with aggressive substances. Furthermore, stainless steel is fully recyclable, aligning with sustainable practices and reducing environmental impact.

Another advantage is the ease of maintenance. Stainless steel does not require extensive upkeep or treatment to maintain its appearance and functionality, making it a cost-effective choice over the long term.

Conclusion

Stainless steel wire and mesh are indispensable materials that cater to a multitude of applications, offering unparalleled durability, aesthetic flexibility, and resistance to corrosion. As industries continue to evolve and demand innovative solutions, the significance of these materials will undoubtedly increase. Whether used in construction, filtration, or decorative applications, stainless steel wire and mesh stand out as a testament to modern engineering and design.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

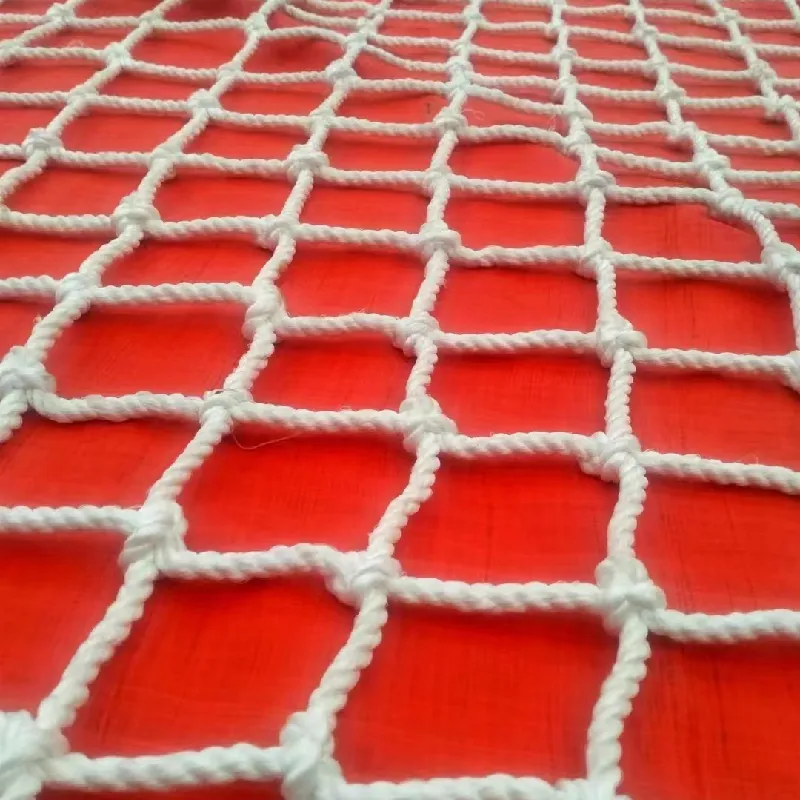

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025