-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

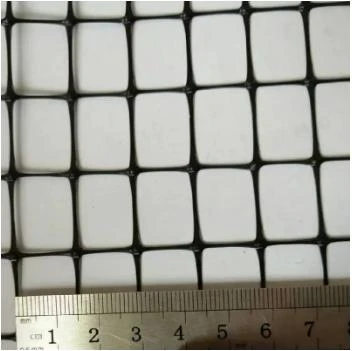

Durable and Versatile Stainless Steel Wire Mesh for Various Applications

The Versatility of Stainless Steel Wire Mesh An In-Depth Look

Stainless steel wire mesh is a versatile material that plays an essential role across a multitude of industries. Known for its durability, strength, and resistance to corrosion, this type of mesh is utilized in applications ranging from filtration to construction. In this article, we will explore the attributes of stainless steel wire mesh, its various uses, and the reasons for its growing popularity.

What is Stainless Steel Wire Mesh?

Stainless steel wire mesh is produced by weaving thin stainless steel strands into a grid pattern. The type of stainless steel used—often either 304 or 316 grade—determines the mesh's properties. The 304 grade is widely used due to its excellent corrosion resistance, while the 316 grade is ideal for more demanding environments, such as marine or chemical applications, because it offers higher resistance to salt and acidic materials.

Key Properties

1. Corrosion Resistance One of the standout features of stainless steel wire mesh is its resistance to rust and corrosion. This makes it an ideal choice for environments where moisture and chemicals are present, ensuring a long lifespan and consistent performance.

2. Strength and Durability Stainless steel is known for its tensile strength and ability to withstand heavy loads and impacts. This durability makes it suitable for a variety of structural and industrial applications.

3. Versatility Stainless steel wire mesh comes in various mesh sizes, wire diameters, and configurations, allowing for tailored solutions based on specific needs.

4. Aesthetic Appeal With its sleek and modern appearance, stainless steel wire mesh is increasingly used in architectural designs. It can add an element of sophistication while offering practical benefits.

stainless steel wire mesh

Applications of Stainless Steel Wire Mesh

1. Filtration In industries such as food and beverage preparation, pharmaceuticals, and water treatment, stainless steel wire mesh is extensively used for filtration purposes. Its uniformity and strength allow for effective separation of particles from liquids or gases.

2. Construction Stainless steel wire mesh is used in concrete reinforcement, as it helps minimize cracking and increases structural integrity. It's also popular in safety barriers, railings, and as infill for fencing solutions.

3. Automotive and Aerospace In these sectors, stainless steel wire mesh is employed in air and fluid filtration systems, helping to ensure efficiency and performance while withstanding extreme conditions.

4. Electronics Stainless steel wire mesh is often used in electronic devices for EMI shielding, protecting sensitive components from electromagnetic interference.

5. Catering and Food Service Many kitchen tools and equipment are constructed from stainless steel wire mesh for its hygiene and cleanliness. It is used in items such as strainers, baskets, and racks.

Conclusion

The utility of stainless steel wire mesh is undeniable, as it offers a combination of strength, versatility, and aesthetic appeal suitable for various applications. Its resistance to corrosion and ability to withstand harsh environments make it a preferred choice in industries ranging from food service to aerospace.

As technology progresses and industries evolve, the demand for stainless steel wire mesh will likely continue to grow, solidifying its importance in both functional and structural applications. Whether utilized for practical purposes or as a design element, stainless steel wire mesh continues to demonstrate its invaluable role in modern manufacturing and design.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025