-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Jan . 21, 2025 03:34

Back to list

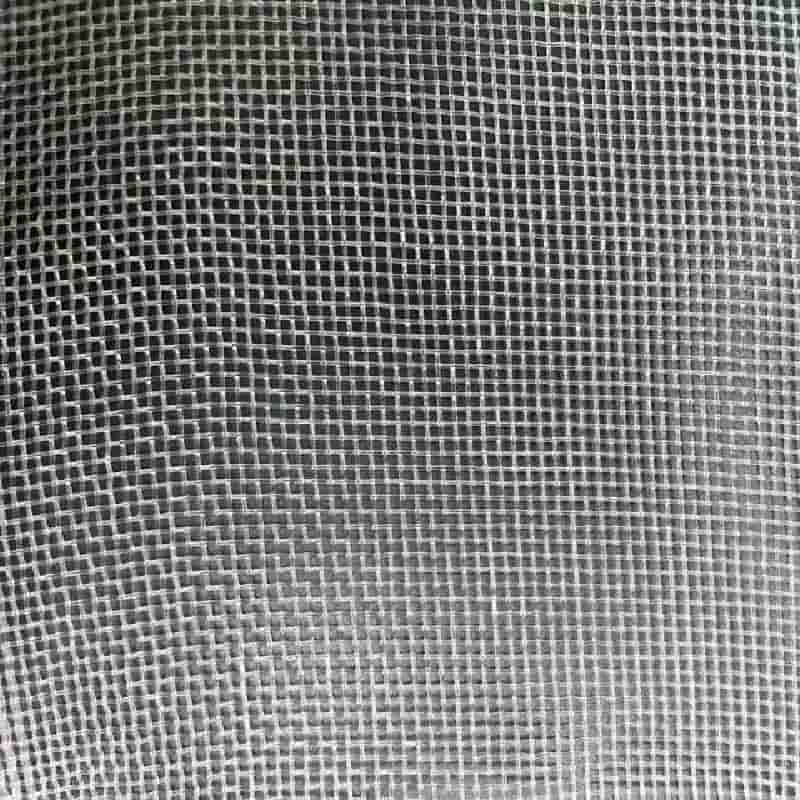

welded wire mesh

Stainless steel wire and mesh play crucial roles in an array of sectors due to their durability, versatility, and resistance to corrosion. As industries evolve, the demand for superior materials to cater to specialized applications has grown. This article provides an in-depth exploration of stainless steel wire and mesh, detailing their properties, uses, and advantages, thus empowering buyers with critical insights.

Trustworthiness plays a pivotal role in choosing the right stainless steel wire and mesh supplier. A trustworthy supplier should provide transparent information regarding the alloy composition, technical specifications, and performance metrics of their products. They should also offer clear warranties and reliable customer support to address any potential issues that arise post-purchase. Besides product reliability, a credible supplier will be environmentally conscious, adhering to environmentally friendly practices in their production processes to minimize the carbon footprint. Real-world experience underscores the value of stainless steel wire and mesh. In construction projects, where structural integrity is paramount, contractors have consistently reported significantly reduced maintenance costs and extended lifespans when using stainless steel mesh. This advantage is particularly beneficial in coastal or industrial environments where exposure to corrosive elements is a concern. Similarly, in automotive applications, stainless steel wire has been critical for components that endure high stress and vibration, confirming its resilience and reliability. Furthermore, innovation in this field continues to advance, with developments like hybrid meshes blending stainless steel with other materials to enhance specific properties like conductivity or thermal resistance. This kind of innovation arises from a solid understanding of material science and a response to evolving market needs, showing the industry's adaptability and forward-thinking strategy. In conclusion, the nuanced world of stainless steel wire and mesh is characterized by unmatched durability, exceptional performance, and an unwavering commitment to quality. Their role in diverse applications—from basic construction to complex industrial uses—highlights their indispensable nature. For businesses seeking reliable and robust materials, investing in stainless steel wire and mesh is a decision that aligns with efficiency, safety, and long-term cost-effectiveness. Engaging with reputable suppliers ensures that these products not only meet but exceed the rigorous demands of modern industry applications.

Trustworthiness plays a pivotal role in choosing the right stainless steel wire and mesh supplier. A trustworthy supplier should provide transparent information regarding the alloy composition, technical specifications, and performance metrics of their products. They should also offer clear warranties and reliable customer support to address any potential issues that arise post-purchase. Besides product reliability, a credible supplier will be environmentally conscious, adhering to environmentally friendly practices in their production processes to minimize the carbon footprint. Real-world experience underscores the value of stainless steel wire and mesh. In construction projects, where structural integrity is paramount, contractors have consistently reported significantly reduced maintenance costs and extended lifespans when using stainless steel mesh. This advantage is particularly beneficial in coastal or industrial environments where exposure to corrosive elements is a concern. Similarly, in automotive applications, stainless steel wire has been critical for components that endure high stress and vibration, confirming its resilience and reliability. Furthermore, innovation in this field continues to advance, with developments like hybrid meshes blending stainless steel with other materials to enhance specific properties like conductivity or thermal resistance. This kind of innovation arises from a solid understanding of material science and a response to evolving market needs, showing the industry's adaptability and forward-thinking strategy. In conclusion, the nuanced world of stainless steel wire and mesh is characterized by unmatched durability, exceptional performance, and an unwavering commitment to quality. Their role in diverse applications—from basic construction to complex industrial uses—highlights their indispensable nature. For businesses seeking reliable and robust materials, investing in stainless steel wire and mesh is a decision that aligns with efficiency, safety, and long-term cost-effectiveness. Engaging with reputable suppliers ensures that these products not only meet but exceed the rigorous demands of modern industry applications.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025