-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 18, 2025 03:44

Back to list

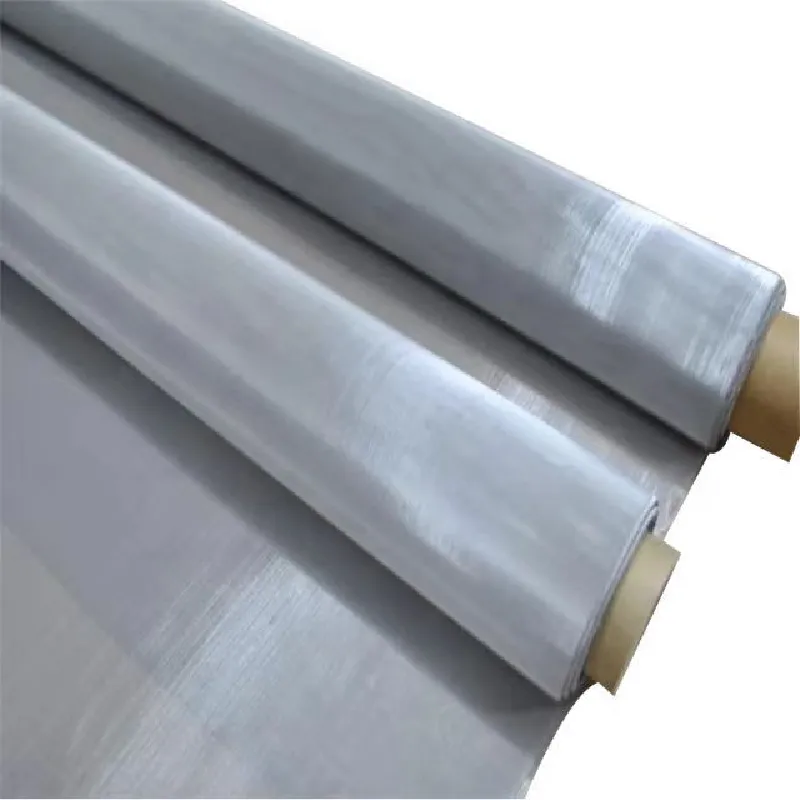

stainless steel wire & mesh

Stainless steel wire and mesh have become indispensable materials in a wide range of industries due to their remarkable properties and versatility. These materials are often the backbone in sectors such as construction, automotive, and even art installations. What sets stainless steel wire and mesh apart is their combination of strength, durability, and resistance to corrosion, making them ideal for both practical and aesthetic applications.

From an expertise standpoint, understanding the grades and specifications of stainless steel wire and mesh is crucial. Different applications require different types of stainless steel. For instance, type 316 stainless steel contains molybdenum, enhancing its corrosion resistance, making it preferable in marine environments. Conversely, type 304 is commonly used for applications where corrosion is less of a concern. Selecting the right type of stainless steel for a specific application involves assessing environmental conditions, mechanical stress, and required aesthetics. Consulting with material scientists and industry experts can provide invaluable insights into which stainless steel variant will provide the best performance and durability for a given project. Trustworthiness and authoritativeness in the stainless steel wire and mesh market come from sourcing materials from reputable suppliers who adhere to industry standards and certifications. Many companies offer testing and traceability for their products, ensuring that customers receive high-quality materials that meet stringent safety and quality benchmarks. In conclusion, the adoption of stainless steel wire and mesh continues to grow across various sectors due to their exceptional properties and adaptability. Their importance in ensuring safety, promoting innovation, and enhancing aesthetic appeal underscores their value in both industrial and creative applications. Companies and individuals looking to utilize stainless steel wire and mesh should prioritize understanding the material's diverse capabilities and consult with industry professionals to make informed decisions that align with their specific needs, ensuring solutions that are both effective and reliable.

From an expertise standpoint, understanding the grades and specifications of stainless steel wire and mesh is crucial. Different applications require different types of stainless steel. For instance, type 316 stainless steel contains molybdenum, enhancing its corrosion resistance, making it preferable in marine environments. Conversely, type 304 is commonly used for applications where corrosion is less of a concern. Selecting the right type of stainless steel for a specific application involves assessing environmental conditions, mechanical stress, and required aesthetics. Consulting with material scientists and industry experts can provide invaluable insights into which stainless steel variant will provide the best performance and durability for a given project. Trustworthiness and authoritativeness in the stainless steel wire and mesh market come from sourcing materials from reputable suppliers who adhere to industry standards and certifications. Many companies offer testing and traceability for their products, ensuring that customers receive high-quality materials that meet stringent safety and quality benchmarks. In conclusion, the adoption of stainless steel wire and mesh continues to grow across various sectors due to their exceptional properties and adaptability. Their importance in ensuring safety, promoting innovation, and enhancing aesthetic appeal underscores their value in both industrial and creative applications. Companies and individuals looking to utilize stainless steel wire and mesh should prioritize understanding the material's diverse capabilities and consult with industry professionals to make informed decisions that align with their specific needs, ensuring solutions that are both effective and reliable.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025