-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

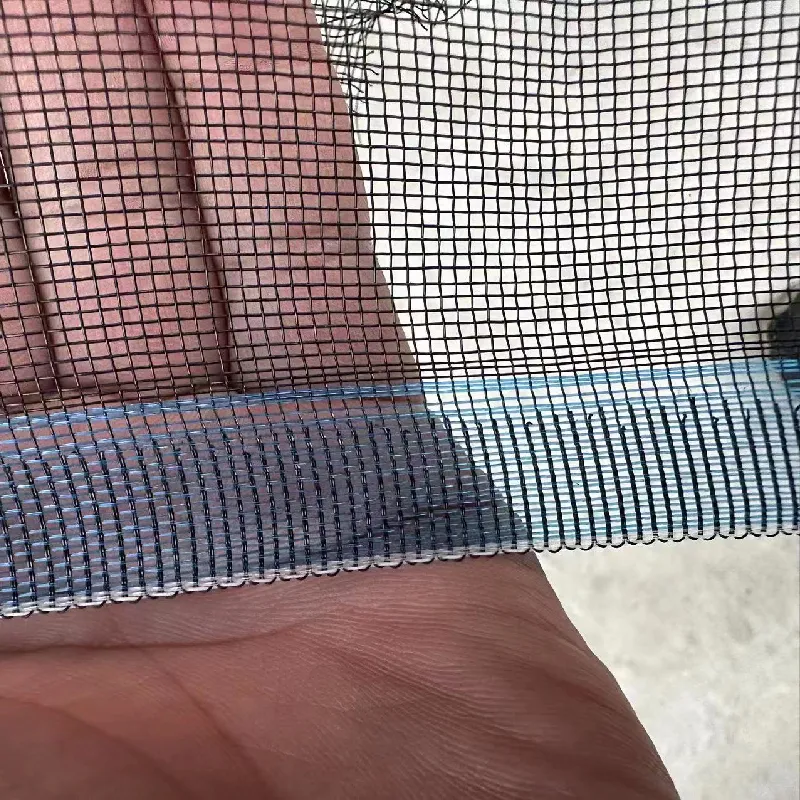

High-Quality Stainless Steel Wire Mesh Filters for Various Applications and Industries

The Versatility and Advantages of Stainless Steel Wire Mesh Filters

Stainless steel wire mesh filters have gained significant popularity across various industries due to their unique properties and versatility. These filters are constructed from interwoven stainless steel wires, which create a robust, durable, and highly effective filtration medium. This article delves into the various applications, benefits, and considerations when using stainless steel wire mesh filters.

Applications of Stainless Steel Wire Mesh Filters

Stainless steel wire mesh filters find applications in numerous fields, including food processing, pharmaceuticals, water treatment, and chemical manufacturing. In the food industry, they are used for separating solids from liquids, maintaining sanitary conditions, and ensuring that products meet safety regulations. Pharmaceutical companies utilize these filters to ensure the purity of their products, preventing contamination during the production process.

In the water treatment sector, stainless steel wire mesh filters play a crucial role in removing unwanted particles from water, thus ensuring cleaner and safer drinking and industrial water supplies. Moreover, industries dealing with chemicals rely on these filters to separate debris and particulate matter from various liquids and gases, ensuring smooth operational processes.

Benefits of Stainless Steel Wire Mesh Filters

One of the most compelling advantages of stainless steel wire mesh filters is their durability. Unlike plastic or other materials, stainless steel is resistant to corrosion, heat, and extreme pressures. This durability extends the operational life of the filters, making them a cost-effective choice for businesses in the long run.

Another significant benefit is their ease of cleaning and maintenance. Stainless steel wire mesh filters can be quickly cleaned, in many cases allowing for reuse, which minimizes waste and operational costs. This is particularly important in industries that demand stringent cleanliness standards, such as food and pharmaceuticals.

The versatility of stainless steel wire mesh filters is another key advantage. They are available in various mesh sizes, allowing for precise control over what particles are filtered out. This adaptability makes them suitable for a wide array of applications, from coarser filtration to fine particulate removal. Additionally, they can be custom-made to fit specific requirements, ensuring that businesses can find the perfect solution for their filtration challenges.

stainless steel wire mesh filter

Environmental and Health Considerations

With rising environmental awareness, many industries are making the shift towards more sustainable practices. Stainless steel wire mesh filters align with these green initiatives as they are reusable and recyclable. By reducing the need for disposable filters that contribute to landfill waste, companies can enhance their sustainability profiles while also reducing costs associated with continuous purchases of filter materials.

Moreover, stainless steel is hypoallergenic and does not leach harmful chemicals into the products being filtered. This characteristic is especially vital in food and pharmaceutical applications, where product safety is paramount.

Challenges and Considerations

While there are numerous benefits to using stainless steel wire mesh filters, some considerations must be kept in mind. For instance, the initial investment may be higher compared to other filtering materials. However, the long-term savings and reduced waste often justify this initial cost.

Furthermore, selecting the appropriate mesh size is crucial. A mesh that is too fine can lead to clogging, increasing pressure and potentially reducing flow rates. Conversely, too coarse a mesh may allow undesired particles to pass through. Therefore, precise specifications are necessary to achieve optimal filtration performance.

Conclusion

Stainless steel wire mesh filters represent a robust, reliable solution for many filtration needs across various industries. Their durability, ease of cleaning, versatility, and eco-friendliness make them an increasingly popular choice among manufacturers and service providers. As technologies advance and industries evolve, the demand for high-performance filtration solutions like stainless steel wire mesh filters is likely to continue growing, underpinning their important role in enhancing product purity and process efficiency.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025