-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Durable Stainless Steel Woven Mesh for Versatile Industrial Applications

Understanding Stainless Steel Woven Mesh Applications and Benefits

Stainless steel woven mesh is a versatile and durable material used in numerous applications across various industries. Its unique properties make it an excellent choice for everything from filtration to architectural design. In this article, we will explore the characteristics, manufacturing process, and applications of stainless steel woven mesh, as well as its benefits over other materials.

Characteristics of Stainless Steel Woven Mesh

Stainless steel woven mesh is made from stainless steel wires that are woven together in a variety of patterns. This weaving process creates a flexible yet strong structure that can withstand both tensile and compressive forces. One of the defining characteristics of stainless steel is its resistance to corrosion, which makes stainless steel woven mesh particularly suitable for environments that are exposed to moisture, chemicals, or extreme temperatures.

The mesh comes in different grades of stainless steel, such as 304, 316, and 430, each with varying levels of corrosion resistance and strength. For instance, 316 stainless steel contains molybdenum, which enhances its corrosion resistance, making it ideal for marine and chemical applications.

Another important aspect of stainless steel woven mesh is its customization potential. Manufacturers can produce mesh in different sizes, widths, and wire diameters, offering flexibility to meet specific requirements. Furthermore, various weaving patterns can create meshes with differing characteristics, such as tighter weaves for finer filtration or looser weaves for increased airflow.

Manufacturing Process

The manufacturing of stainless steel woven mesh involves several steps, starting with selecting the appropriate wire material. Once the wire has been chosen, it is drawn to the desired diameter and then rolled into coils. The wires are then woven using automated or manual looms, depending on the complexity of the pattern and the specifications requested by the client.

After the weaving process, the mesh is often subjected to treatments that may include heat setting or stretching to enhance its dimensional stability and strength. The final product is then inspected for quality to ensure it meets the industry standards required for its intended application.

Applications of Stainless Steel Woven Mesh

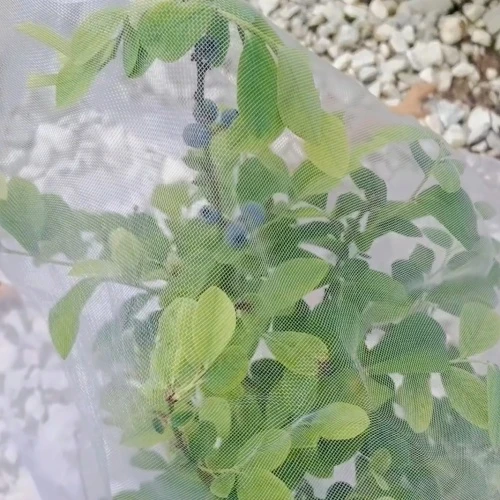

stainless woven mesh

Stainless steel woven mesh has a wide range of applications. One of the most common uses is in filtration systems. The mesh is used in various industries, including food and beverage, pharmaceuticals, and mining, where it serves as a barrier to separate solid particles from liquids, gases, or other solids, ensuring purity and efficiency.

In architectural design, stainless steel woven mesh is gaining popularity. Its aesthetic appeal and structural integrity make it an excellent choice for facades, railings, and interior designs. The ability to allow light and air to permeate, while still offering privacy and security, adds to its charm in modern architecture.

Stainless steel woven mesh is also widely used in industrial applications, such as in the production of sieves, security screens, and protective barriers. Its strength and durability make it a reliable choice for harsh environments where conventional materials may fail.

Benefits Over Other Materials

One of the primary advantages of stainless steel woven mesh over other filtering or screening materials is its durability. Unlike plastic or fabric meshes, stainless steel does not degrade over time, especially in challenging environments. This longevity translates into lower maintenance costs and increased operational efficiency.

Another benefit is its recyclability. Stainless steel is one of the most recycled materials in the world. When the woven mesh reaches the end of its life cycle, it can be easily repurposed, contributing to a more sustainable manufacturing process.

Additionally, the aesthetic quality of stainless steel woven mesh opens up design possibilities that other materials cannot match. Its modern, sleek appearance can be integrated into various design schemes, enhancing not only functionality but also the visual appeal of the structures it is used in.

Conclusion

Stainless steel woven mesh stands out as a highly versatile, durable, and aesthetically pleasing material that caters to a multitude of applications. Its unique properties, coupled with its sustainability, make it an ideal choice for industries ranging from architecture to manufacturing. As technology continues to advance, the potential uses for stainless steel woven mesh are likely to expand, further solidifying its importance in modern applications.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025