-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Mar . 06, 2025 11:26

Back to list

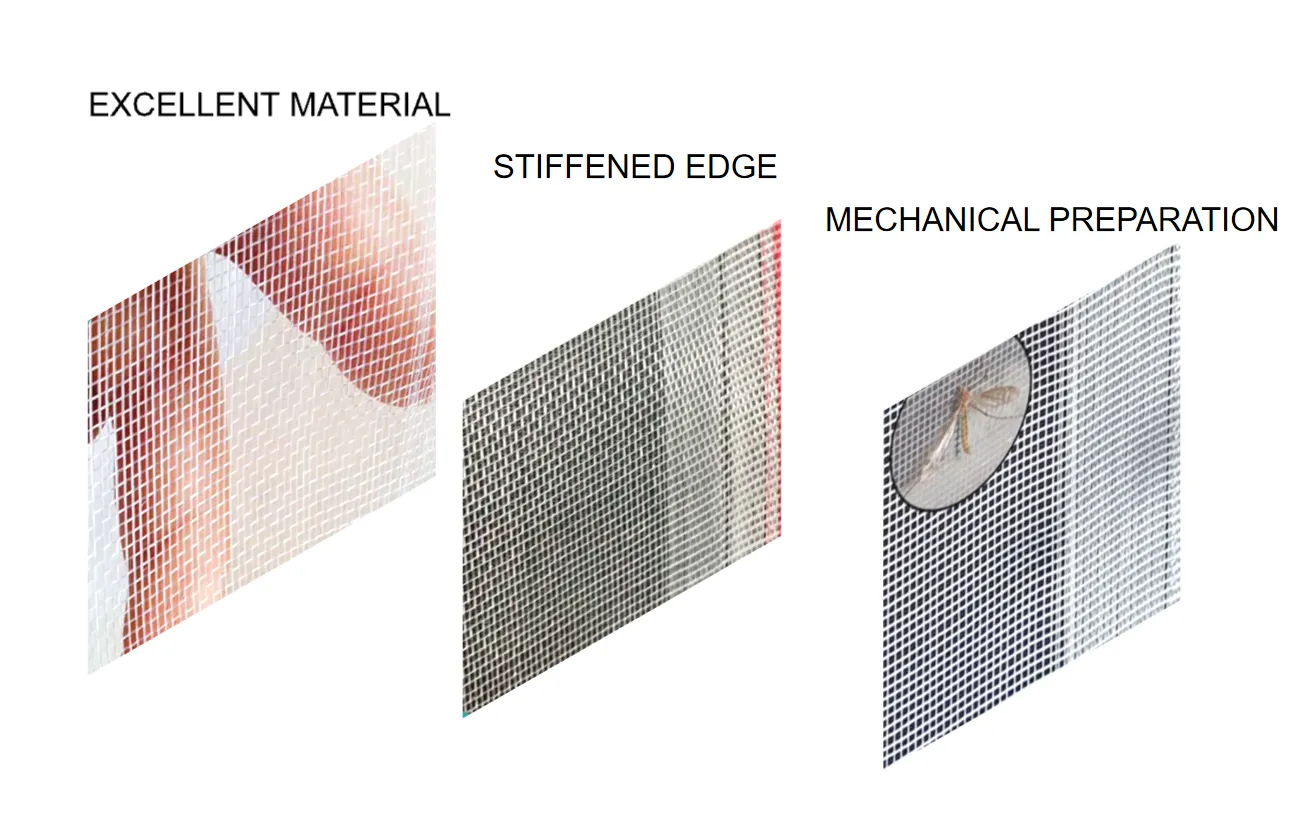

stainless woven mesh

Stainless woven mesh stands as a testament to durability and innovation in the field of materials. Its widespread application across industries is a reflection of its versatility and robust characteristics. This mesh type is not simply a product; it’s a solution engineered to meet complex industrial needs, ensuring safety, durability, and efficiency.

Moreover, the authority of stainless woven mesh suppliers is fortified by their adherence to international standards, ensuring each product meets the requisite safety and quality assurances. This commitment to quality is evident in comprehensive testing processes that include tensile strength testing, corrosion resistance assessments, and dimensional accuracy checks, aligning the product with global expectations and ensuring it stands as a trusted solution for engineers, architects, and industry professionals. Trust in stainless woven mesh is built upon decades of proven performance and continuous innovation. Advances in weaving technology have allowed the development of specialized patterns such as plain weave, twill weave, and Dutch weave, each providing distinct characteristics for specialized applications. This innovation ensures that industries can rely on stainless woven mesh products to evolve alongside changing technological demands and environmental considerations. In addition, customer experiences widely affirm the reliability of stainless woven mesh. Testimonials often highlight its long service life, minimal maintenance requirements, and exceptional performance under demanding conditions. For businesses and industries seeking a resilient solution, stainless woven mesh delivers results, consistently outperforming lesser materials over time, thereby affirming its position as a premier choice in mission-critical applications. In conclusion, choosing stainless woven mesh means investing in a future-proof solution. Its unmatched blend of strength, flexibility, and corrosion resistance renders it an irreplaceable asset across numerous industrial sectors. With its roots deeply set in expertise, backed by authoritative manufacturing and trusted performance, stainless woven mesh not only meets the rigorous demands of the present but also anticipates the needs of tomorrow's industries.

Moreover, the authority of stainless woven mesh suppliers is fortified by their adherence to international standards, ensuring each product meets the requisite safety and quality assurances. This commitment to quality is evident in comprehensive testing processes that include tensile strength testing, corrosion resistance assessments, and dimensional accuracy checks, aligning the product with global expectations and ensuring it stands as a trusted solution for engineers, architects, and industry professionals. Trust in stainless woven mesh is built upon decades of proven performance and continuous innovation. Advances in weaving technology have allowed the development of specialized patterns such as plain weave, twill weave, and Dutch weave, each providing distinct characteristics for specialized applications. This innovation ensures that industries can rely on stainless woven mesh products to evolve alongside changing technological demands and environmental considerations. In addition, customer experiences widely affirm the reliability of stainless woven mesh. Testimonials often highlight its long service life, minimal maintenance requirements, and exceptional performance under demanding conditions. For businesses and industries seeking a resilient solution, stainless woven mesh delivers results, consistently outperforming lesser materials over time, thereby affirming its position as a premier choice in mission-critical applications. In conclusion, choosing stainless woven mesh means investing in a future-proof solution. Its unmatched blend of strength, flexibility, and corrosion resistance renders it an irreplaceable asset across numerous industrial sectors. With its roots deeply set in expertise, backed by authoritative manufacturing and trusted performance, stainless woven mesh not only meets the rigorous demands of the present but also anticipates the needs of tomorrow's industries.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025