-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

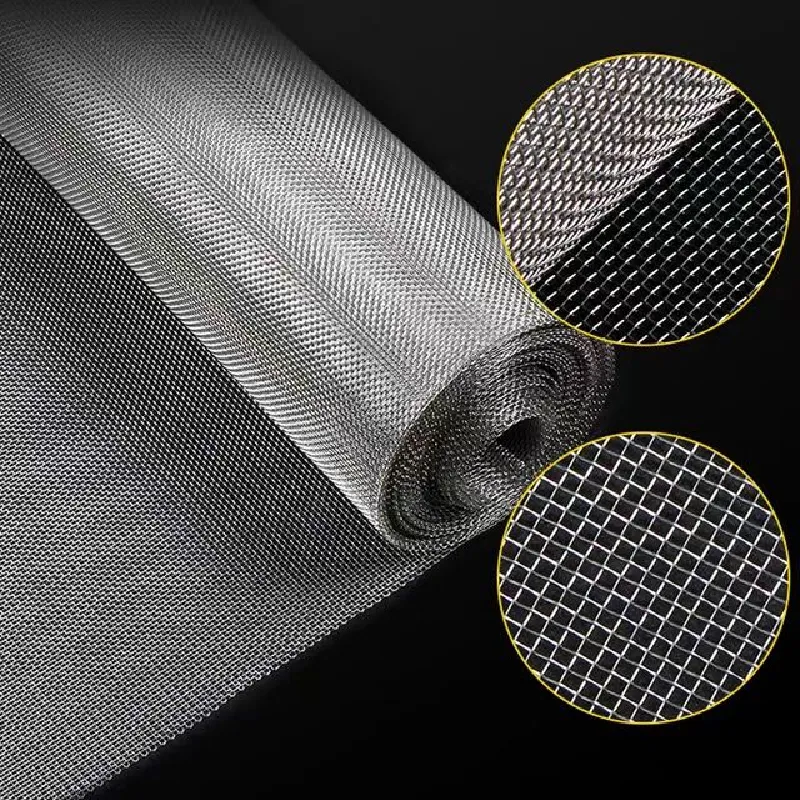

stainless woven wire mesh

Understanding Stainless Woven Wire Mesh Its Applications and Advantages

Stainless woven wire mesh is a versatile material made from stainless steel wire that is woven into a grid pattern. This unique manufacturing process ensures that the mesh is durable, resilient, and suitable for a wide range of applications across various industries. With its exceptional strength and resistance to corrosion, stainless woven wire mesh is favored in settings where durability and hygiene are paramount.

Composition and Manufacturing Process

Stainless woven wire mesh is primarily composed of different grades of stainless steel, such as 304 and 316. The choice of material depends on the specific application, as different grades offer various levels of corrosion resistance, strength, and temperature tolerance. The manufacturing process involves weaving the stainless steel wire in such a way that it creates small openings between the wires, forming a mesh structure. This weaving can be done in various patterns, including plain weave, twill weave, and Dutch weave, each providing distinct characteristics suitable for specific uses.

Key Properties

1. Corrosion Resistance One of the most notable properties of stainless woven wire mesh is its ability to withstand rust and corrosion. This is especially important in environments exposed to moisture and chemicals, such as food processing plants, marine applications, and chemical manufacturing.

2. Durability The robust nature of stainless steel ensures that woven wire mesh can endure mechanical stress and abrasion. It does not easily break or deform, making it ideal for applications that require a strong and long-lasting material.

3. Aesthetic Appeal Beyond functionality, stainless woven wire mesh also has a modern and sleek appearance. Its shiny surface and clean lines make it an attractive choice for architectural applications, such as decorative facades or interior design elements.

stainless woven wire mesh

Applications

Stainless woven wire mesh finds use in a wide range of industries due to its diverse properties and adaptability. Here are a few notable applications

1. Filtration In industries such as food and beverage, pharmaceuticals, and water treatment, stainless woven wire mesh is commonly used for filtration purposes. Its precise openings can be engineered to trap specific contaminants while allowing liquids or gases to pass through.

2. Separation In the mining and aggregate industries, stainless woven wire mesh serves as a separator for various materials, ensuring that products are appropriately sized and classified.

3. Architectural Design The aesthetic appeal and structural strength of stainless woven wire mesh make it a popular choice in architecture. It can be used for facades, railings, partitions, and even artwork, providing both functional and visual value.

4. Cages and Screens From industrial cages to screens for pest control, stainless woven wire mesh offers strong protection and durability. It can be used in agricultural settings, such as livestock enclosures, or in residential environments to keep pests at bay.

5. Safety and Security Stainless woven wire mesh is often used in safety applications, including guards, safety screens, and reinforced barriers. Its robust nature ensures it can withstand significant impacts, making it ideal for protecting people and property.

Conclusion

Stainless woven wire mesh is a remarkable material that combines the strength and resilience of stainless steel with a versatile design that can be adapted for countless applications. Its resistance to corrosion, durability, and aesthetic appeal make it a go-to choice for architects, engineers, and manufacturers alike. As industries continue to seek innovative materials that meet both functional and aesthetic needs, stainless woven wire mesh is expected to remain a prominent solution, supporting a wide array of applications while proving its worth in safety, design, and durability. Whether in the realm of filtration, construction, or decorative arts, the benefits of stainless woven wire mesh are undeniable, and its ongoing relevance in modern industry is assured.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025