-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

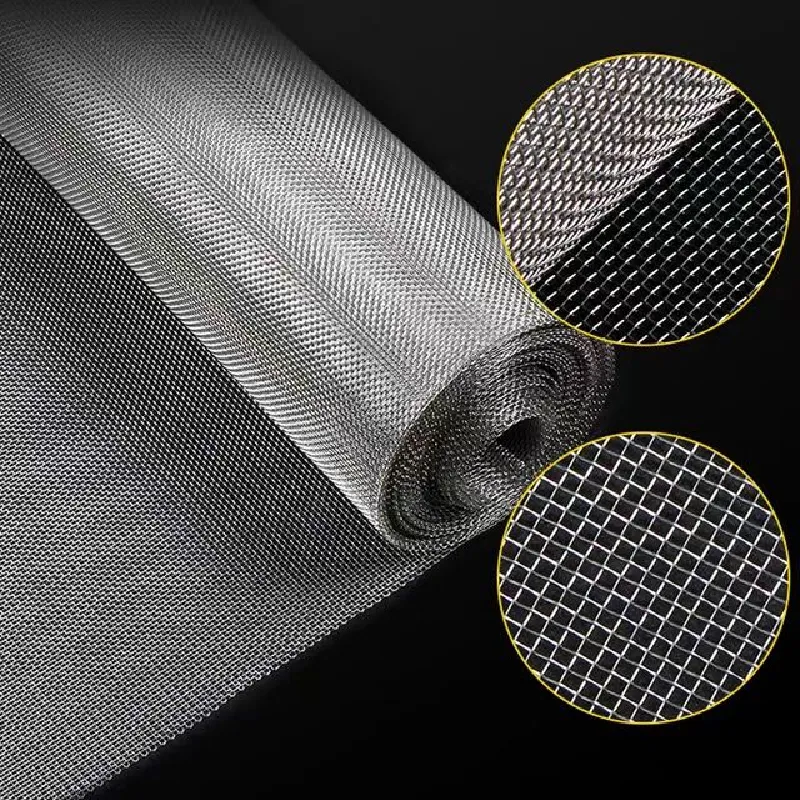

stainless woven wire mesh

The Versatility and Benefits of Stainless Steel Woven Wire Mesh

Stainless steel woven wire mesh is a highly valuable material that has found applications across various industries due to its unique properties and versatility. This mesh is created by weaving together stainless steel wires, resulting in a sturdy and durable product that can be tailored to meet specific needs.

Composition and Types of Stainless Steel

Stainless steel is an alloy that primarily consists of iron, carbon, and a minimum of 10.5% chromium. The addition of chromium provides corrosion resistance and enhances the material's durability. There are various grades of stainless steel, with types 304 and 316 being the most common in wire mesh applications.

- Type 304 is widely used due to its excellent corrosion resistance and good mechanical properties. It is suitable for a range of mild corrosive environments. - Type 316, containing molybdenum, offers superior resistance to chlorides and is ideal for marine and industrial applications where exposure to chemicals is a concern.

Weaving Techniques

The weaving process of stainless steel wire mesh can vary significantly, resulting in different patterns and openings. Common techniques include plain weave, twill weave, and Dutch weave, each offering distinct mechanical and filtration properties.

- Plain Weave This method features wires woven at right angles to create a tight mesh. It provides uniform openings and is typically used in applications requiring high strength.

- Twill Weave In this style, the wires are woven in a manner that creates a diagonal pattern. This approach increases flexibility and is beneficial for applications where greater durability is necessary.

- Dutch Weave This technique uses thicker warp wires with thinner weft wires, resulting in excellent filtering capabilities. Dutch weave mesh is often used in applications requiring fine filtration and high strength.

Applications Across Industries

stainless woven wire mesh

The applications of stainless steel woven wire mesh are vast and varied. Some of the key industries that utilize this versatile material include

1. Food and Beverage Industry Stainless steel mesh is frequently used in the production of food and beverages due to its hygiene standards and resistance to corrosion. It is often employed in filtering, sifting, and processing applications.

2. Pharmaceuticals In this industry, the need for high cleanliness and contamination control is paramount. Stainless steel woven wire mesh provides the necessary properties for filtration and separation processes, ensuring that products remain uncontaminated.

3. Mining and Aggregate Stainless steel mesh is utilized in screening and sorting mineral products. Its strength and durability make it ideal for harsh environments found in mining operations.

4. Architecture and Interior Design The aesthetic appeal of stainless steel woven wire mesh has led to its use in various architectural applications, such as facades, railings, and decorative elements. Its unique appearance adds a modern touch while maintaining strength.

5. Automotive and Aerospace In these sectors, stainless steel mesh is often used in manufacturing components that require robust materials, such as filters and screens that can withstand extreme conditions.

Benefits of Stainless Steel Woven Wire Mesh

The advantages of using stainless steel woven wire mesh are numerous. Firstly, its resistance to corrosion ensures longevity and durability, making it a cost-effective choice in the long run. Additionally, the strength of stainless steel allows for the creation of products that can endure high pressures and harsh conditions.

Furthermore, the material is easily customizable, with options available for different wire diameters, mesh openings, and weaves. This customization allows industries to select the perfect mesh for their specific needs. The mesh is also easy to clean and maintain, further boosting its appeal.

Conclusion

In conclusion, stainless steel woven wire mesh is an essential material that plays a significant role in numerous industries. Its durability, resistance to corrosion, and versatility make it an invaluable resource for applications ranging from food and pharmaceuticals to architecture and aerospace. As industries continue to seek reliable materials, the relevance of stainless steel woven wire mesh is sure to grow, reinforcing its position as a backbone in modern manufacturing and design. Whether for functional or aesthetic purposes, the applications of this remarkable material are virtually limitless, proving its significant role in our everyday lives.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025