-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 18, 2025 08:49

Back to list

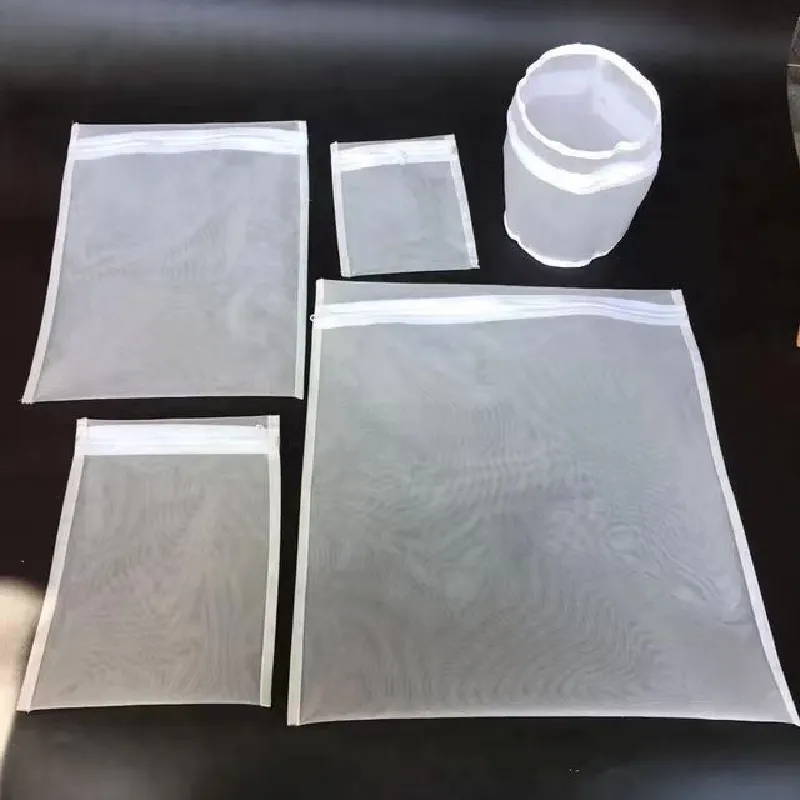

sun shade mesh

Incorporating steel fibers into concrete has transformed how engineers and architects approach construction, blending traditional methodologies with modern innovation to enhance structural integrity. These fibers have captivated the industry with their multitude of benefits, presenting an opportunity to redefine concrete applications.

The ecological impact of using steel fibers in concrete also merits attention. Steel fibers are often manufactured from recycled steel, promoting sustainability in construction practices. Furthermore, as they enable the use of thinner concrete slabs without sacrificing strength, the overall material usage is decreased, leading to less resource consumption and waste production. Embracing SFRC can be part of a broader strategy to achieve environmentally friendly construction standards. SFRC's performance advantages extend beyond structural improvements. The aesthetic possibilities are notable; architects can experiment with thinner, more intricate designs without fear of compromising strength. This freedom opens up a new realm of creative potential, allowing for daring architectural feats that challenge traditional construction limits. Leading authorities in civil engineering and construction management consistently recognize steel fiber technology. Their studies have demonstrated SFRC's superior performance in various environments, further solidifying its reputation as a reliable and advanced concrete innovation. These endorsements provide compelling evidence of the product’s authority in the field and reinforce the trust construction professionals place in steel fiber solutions. In conclusion, the strategic use of steel fibers in concrete constructs a narrative of modern efficiency, sustainability, and resilience. As demands increase for structures that can withstand the test of time while maintaining aesthetic and environmental harmony, SFRC stands at the forefront, embodying the union of strength and sophistication. Adopting steel fiber technology proves indispensable for stakeholders aiming to align with future-forward construction practices.

The ecological impact of using steel fibers in concrete also merits attention. Steel fibers are often manufactured from recycled steel, promoting sustainability in construction practices. Furthermore, as they enable the use of thinner concrete slabs without sacrificing strength, the overall material usage is decreased, leading to less resource consumption and waste production. Embracing SFRC can be part of a broader strategy to achieve environmentally friendly construction standards. SFRC's performance advantages extend beyond structural improvements. The aesthetic possibilities are notable; architects can experiment with thinner, more intricate designs without fear of compromising strength. This freedom opens up a new realm of creative potential, allowing for daring architectural feats that challenge traditional construction limits. Leading authorities in civil engineering and construction management consistently recognize steel fiber technology. Their studies have demonstrated SFRC's superior performance in various environments, further solidifying its reputation as a reliable and advanced concrete innovation. These endorsements provide compelling evidence of the product’s authority in the field and reinforce the trust construction professionals place in steel fiber solutions. In conclusion, the strategic use of steel fibers in concrete constructs a narrative of modern efficiency, sustainability, and resilience. As demands increase for structures that can withstand the test of time while maintaining aesthetic and environmental harmony, SFRC stands at the forefront, embodying the union of strength and sophistication. Adopting steel fiber technology proves indispensable for stakeholders aiming to align with future-forward construction practices.

Next:

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025