-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

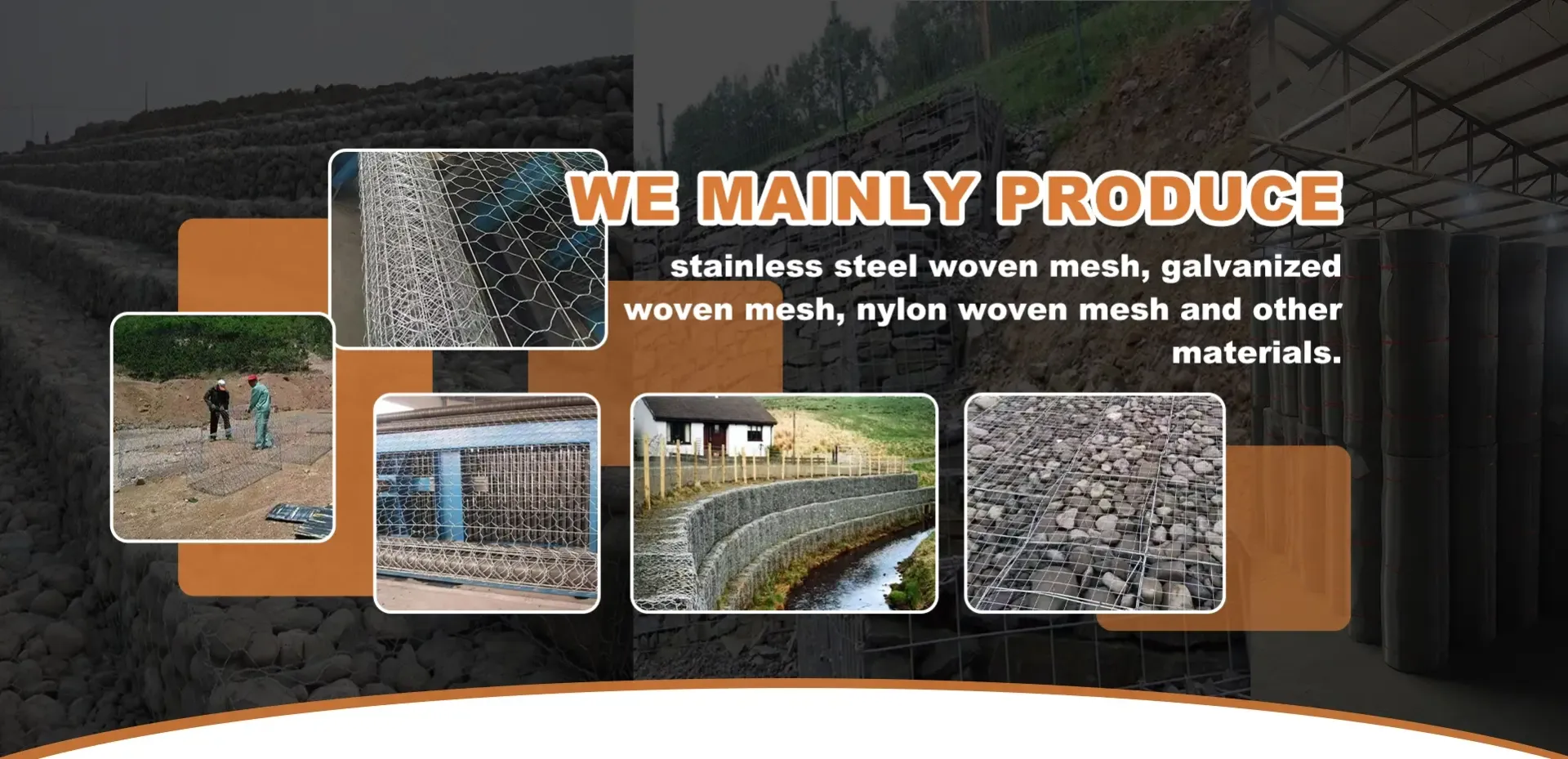

Innovative Steel Mesh Solutions for Enhanced Durability and Structural Integrity

The Significance of Steel Mesh An Overview

Steel mesh, an essential material in construction and manufacturing, plays a critical role in enhancing structural integrity. This article explores the various aspects of steel mesh, including its types, applications, benefits, and its evolving role in modern engineering.

Understanding Steel Mesh

Steel mesh refers to a network of steel bars or wires that are interconnected to form a grid-like structure. It can be made from different grades of steel, providing varying levels of strength and durability. The two most common types of steel mesh are welded wire mesh and woven wire mesh. Welded wire mesh consists of steel wires that are welded at intersections, creating a strong, stable framework. In contrast, woven wire mesh is made by interlacing steel wires to form a flexible and adaptable grid pattern.

Applications of Steel Mesh

The applications of steel mesh are incredibly diverse. In the construction industry, it is primarily used to reinforce concrete, acting as a form of internal support that enhances tensile strength. This is particularly important in structures such as bridges, roads, and buildings, where load-bearing capabilities are paramount.

Moreover, steel mesh is extensively used in fencing applications, providing security and protection for properties. Its durability and resistance to weather conditions make it suitable for agricultural, commercial, and residential fencing needs. From livestock enclosures to park boundaries, steel mesh fencing helps define spaces while ensuring safety.

Another significant application of steel mesh is in the manufacturing sector, where it is often employed in the production of filters and sieves. Its robust construction allows for effective separation of materials, whether in industrial processes or in the food and beverage industry, where hygiene and strength are crucial.

Benefits of Using Steel Mesh

steel mesh

The use of steel mesh offers numerous benefits, making it a preferred choice in various applications. One of its primary advantages is its strength. The inherent properties of steel provide high resistance to bending, stretching, and deformation, ensuring the longevity of structures.

Furthermore, steel mesh is cost-effective. It requires minimal maintenance and has a long lifespan, which reduces the need for frequent replacements and repairs. This makes it an economically viable option for developers and manufacturers alike.

Another significant benefit is the versatility of steel mesh. It can be produced in various sizes, shapes, and configurations to meet specific project requirements. Whether it's for intricate architectural designs or straightforward structural reinforcement, steel mesh can adapt to different needs.

The Future of Steel Mesh

As the construction and manufacturing industries continue to evolve, so does the role of steel mesh. With advancements in technology, new methods of producing steel mesh are emerging, enhancing the material's performance characteristics. Innovations such as galvanized steel mesh are becoming popular, as they offer increased corrosion resistance, making them suitable for harsher environments.

Additionally, the integration of smart technologies is on the horizon. Future developments may see steel mesh embedded with sensors capable of monitoring structural integrity in real time. This could revolutionize maintenance protocols, allowing for timely interventions that could prevent failures and extend the life of structures.

Furthermore, as sustainability becomes a growing concern, the steel industry is also moving towards more eco-friendly practices. Recycled steel mesh is expected to gain traction, allowing for sustainable construction practices that reduce waste and the overall environmental impact.

Conclusion

In conclusion, steel mesh is a vital component in the construction and manufacturing sectors. Its strength, versatility, and cost-effectiveness make it indispensable for various applications, from reinforcing structures to providing security. As technology and sustainability practices continue to advance, steel mesh is poised to play an even more significant role in future developments. The ongoing innovations in production methods and materials will undoubtedly enhance its applications, ensuring that steel mesh remains a cornerstone in engineering for years to come.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025