-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Exploring the Applications and Benefits of Steel Mesh in Construction Industry

Understanding Steel Mesh Importance, Applications, and Manufacturing

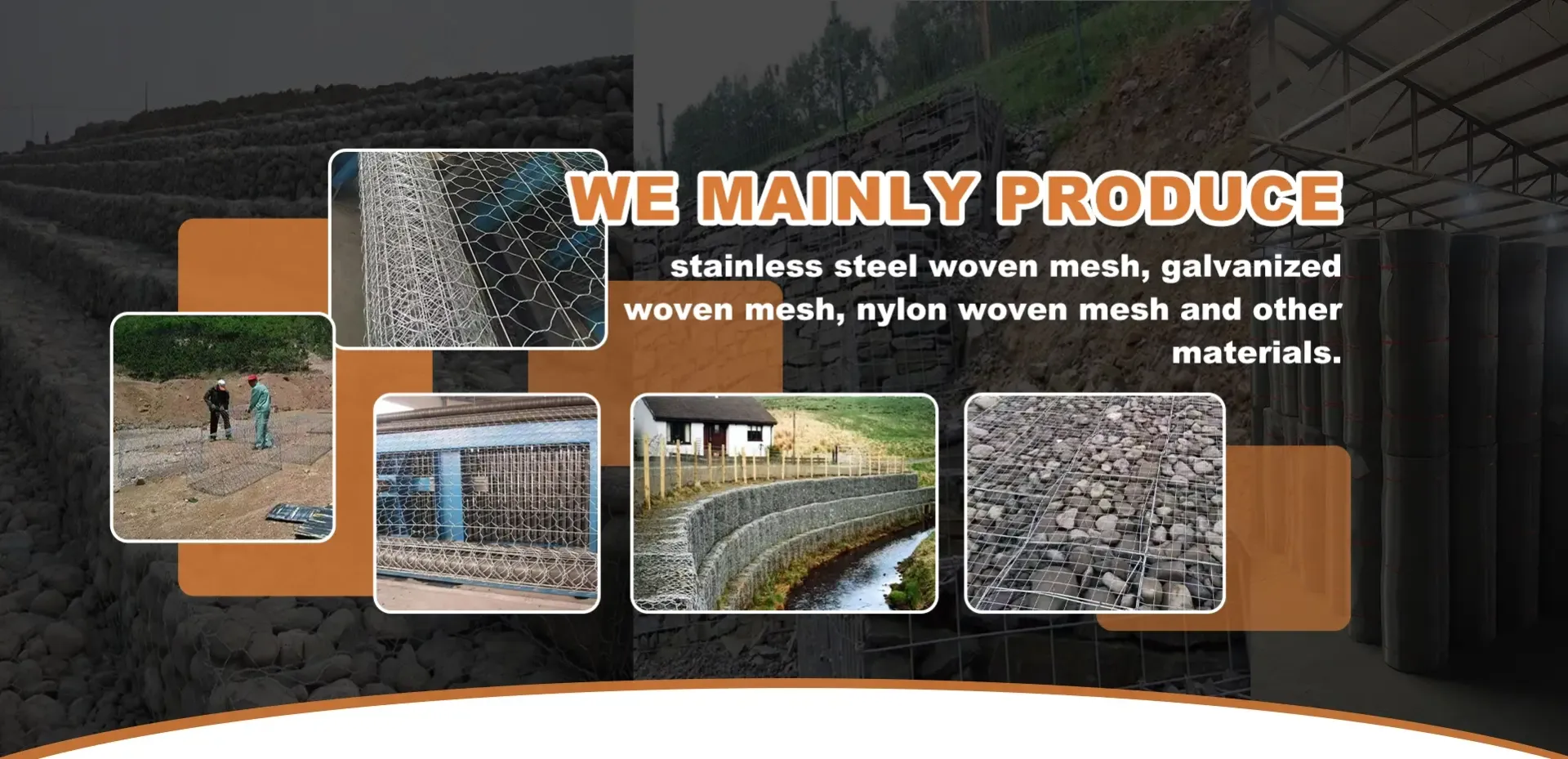

Steel mesh, an essential component in various construction and manufacturing processes, has gained significant attention in recent years due to its versatility and durability. Composed of interwoven steel wires or rods, steel mesh provides structural support, reinforcement, and aesthetic value in a myriad of applications. This article delves into the importance, applications, and manufacturing processes of steel mesh, underscoring its integral role in modern infrastructure.

Importance of Steel Mesh

The primary function of steel mesh is to reinforce materials such as concrete, ensuring durability and stability. In construction, the mesh distributes loads evenly, reducing stress on individual elements and minimizing the risk of cracking. By enhancing the tensile strength of concrete, steel mesh is crucial in reinforcing slabs, walls, roads, and bridges. Furthermore, it serves as a barrier, preventing the spread of fire and protecting against water and environmental damage.

Another significant advantage of steel mesh is its cost-effectiveness. Its ability to increase the longevity of structures helps to reduce maintenance costs over time. Additionally, the use of steel mesh can streamline the construction process, allowing for faster project completion. As construction projects become increasingly complex, the efficiency provided by steel mesh becomes increasingly valuable, meeting the demands of modern engineering.

Applications of Steel Mesh

Steel mesh finds applications across numerous industries, and its use extends beyond construction. Here are some of the primary areas where steel mesh is utilized

1. Construction and Civil Engineering As previously mentioned, steel mesh is primarily used for reinforcing concrete. It is employed in various structures, including foundations, beams, columns, and slabs. Additionally, it is essential in creating precast concrete elements.

2. Road Construction In the development of roads and highways, steel mesh plays a critical role by providing stability and enhancing the lifespan of pavement structures. It is consistently used in concrete overlays, helping to distribute loads and resist cracking from vehicle traffic.

3. Mining and Tunneling Steel mesh is employed in the mining industry to provide structural support and stabilization in tunnels and underground excavations. It helps prevent collapses by reinforcing the rock and soil surrounding tunnels.

steel mesh

4. Architecture and Design Beyond its functional aspects, steel mesh is also used as a design element in architecture. Its aesthetic appeal allows architects to create intricate designs for facades, railings, and partitions while maintaining structural integrity.

5. Agriculture In agriculture, steel mesh is commonly used for fencing, animal enclosures, and trellises. Its sturdy construction ensures durability against weather conditions and animal interactions.

6. Manufacturing Steel mesh is utilized in various manufacturing processes, including filtration, sieving, and even as a component in industrial safety barriers. Its ability to provide strength and support while allowing for air and light passage makes it ideal for numerous applications.

Manufacturing of Steel Mesh

The manufacturing process of steel mesh typically involves the following steps

1. Wire Preparation Steel rods or wires are drawn into thin strands of the desired gauge. The reduction to precise diameters is crucial for ensuring the overall strength and durability of the mesh.

2. Weaving The prepared wires are woven together in specific patterns to form the mesh. This weaving process can be done using various techniques, including welded mesh, woven mesh, or chain-link styles, each serving different applications and requirements.

3. Surface Treatment To enhance corrosion resistance and longevity, the finished steel mesh undergoes surface treatments such as galvanization or coating. These processes protect the mesh from environmental factors that could lead to deterioration.

4. Quality Control Rigorous quality control measures are implemented to ensure that the finished product meets industry standards. This includes checking dimensions, strength tests, and assessments for any imperfections.

In conclusion, steel mesh is a vital material in today's construction and manufacturing landscapes. Its role in enhancing the strength and stability of structures, coupled with its versatility across various applications, confirms its importance. As industries continue to evolve, the demand for quality steel mesh is likely to increase, paving the way for advancements in its manufacturing and applications. Whether in civil engineering, architecture, or agriculture, steel mesh remains an indispensable resource that supports the foundations of our built environment.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025