-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

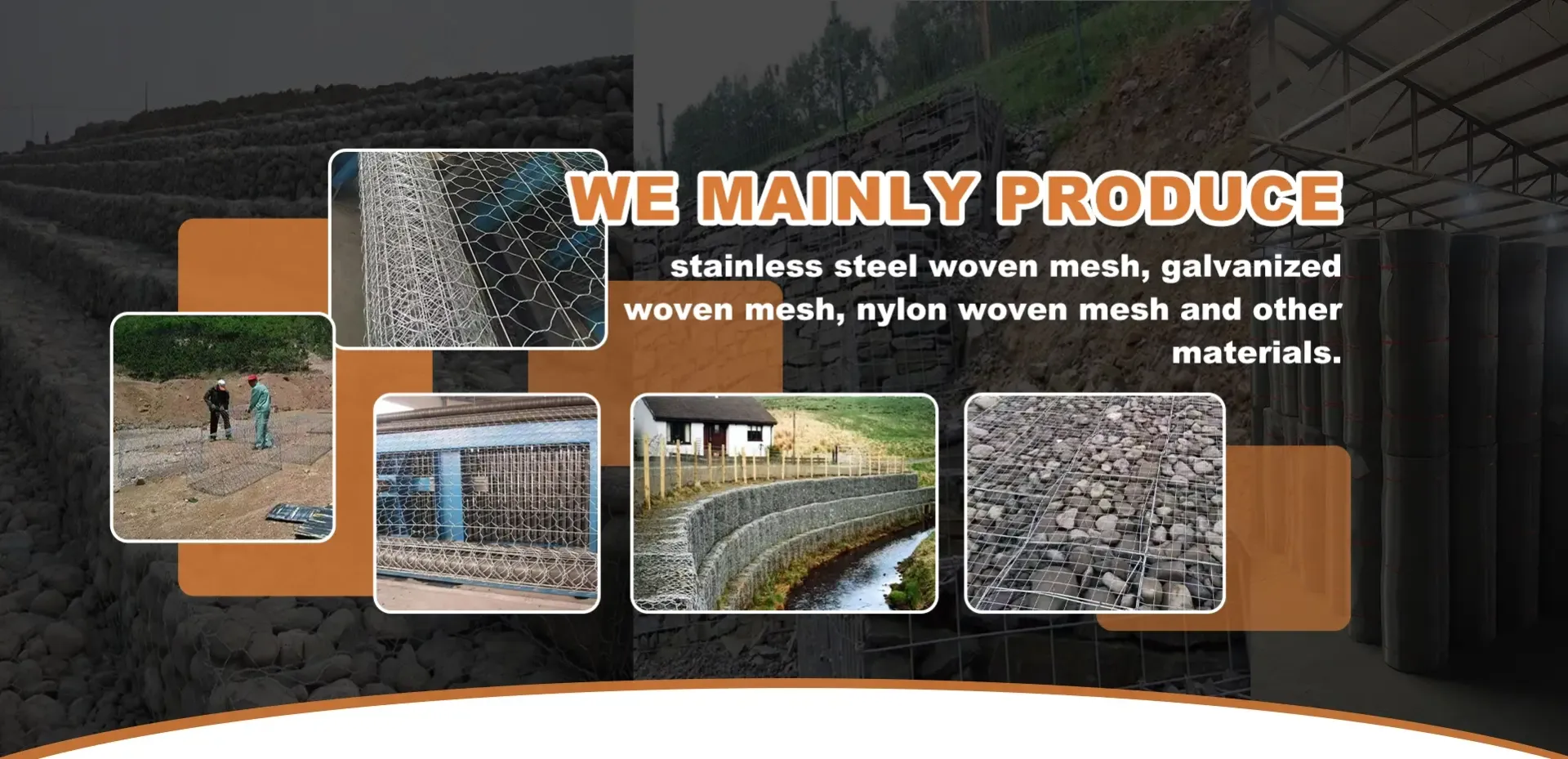

steel mesh manufacturers

The Importance of Steel Mesh Manufacturers in Modern Construction

Steel mesh, a versatile and crucial component in construction, is widely used for various applications, from reinforcing concrete to providing safety barriers. The role of steel mesh manufacturers is essential in this sector, as they produce high-quality products that meet the specific needs of engineers and builders. Understanding the significance of these manufacturers can help stakeholders appreciate the value that steel mesh brings to construction projects.

One of the primary functions of steel mesh is to reinforce concrete structures. Concrete is a strong material in compression but is weak in tension. By incorporating steel mesh into concrete, manufacturers create a composite material that enhances the tensile strength of the concrete, allowing it to bear heavier loads and withstand various stresses. This characteristic makes steel mesh an indispensable element in the construction of roads, bridges, buildings, and other infrastructure projects.

Moreover, steel mesh manufacturers provide various types of mesh, including Welded Wire Fabric (WWF), welded mesh, and hexagonal mesh, each designed for specific applications. For instance, WWF is often used in slabs and pavements, while hexagonal mesh is preferred in applications such as animal cages and fencing products. By offering a diverse range of products, steel mesh manufacturers cater to the unique requirements of different construction projects, enabling architects and engineers to select the right materials for their designs.

steel mesh manufacturers

Another critical aspect of steel mesh manufacturing is compliance with industry standards. Leading manufacturers adhere to strict quality control measures and comply with international standards such as ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization). This commitment to quality ensures that the steel mesh produced can handle the rigors of construction, providing safety and reliability for end-users. It also helps construction companies avoid costly delays and potential hazards caused by inferior materials.

In addition to quality and compliance, many steel mesh manufacturers are embracing technological advancements. The introduction of automated manufacturing processes, including robotic welding and computer-aided design (CAD), has significantly improved the precision and efficiency of steel mesh production. This technological shift not only enhances product quality but also reduces lead times, ensuring that construction projects stay on schedule. Furthermore, some manufacturers are incorporating eco-friendly practices in their production processes, utilizing recycled steel and reducing waste, aligning with global sustainability goals.

As urbanization continues to rise, the demand for steel mesh in construction is expected to grow. Steel mesh manufacturers will play a pivotal role in meeting this demand by consistently delivering innovative and high-quality products. They also must focus on customer service, providing valuable support and guidance to contractors and engineers in selecting the most appropriate products for their specific needs.

In conclusion, steel mesh manufacturers are integral to the construction industry, supplying essential materials that enhance the safety, durability, and efficiency of various structures. By prioritizing quality, embracing technology, and understanding the evolving needs of the construction sector, these manufacturers contribute significantly to building a more resilient infrastructure for the future. As the industry continues to evolve, the influence and importance of steel mesh manufacturers will undoubtedly grow, making them key players in the construction landscape.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025