-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Top Steel Mesh Suppliers for Quality and Durability in Your Construction Projects

The Rise of Steel Mesh Manufacturers An Integral Part of Modern Construction

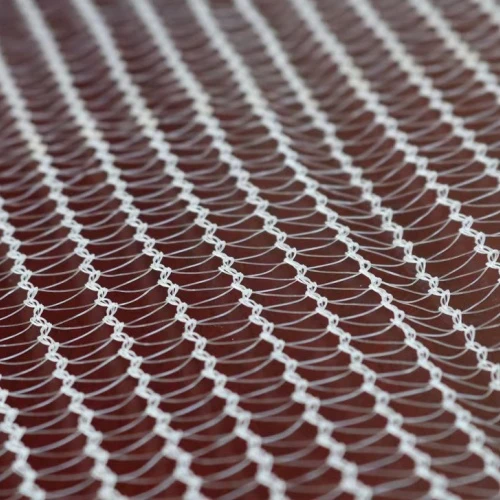

In the contemporary world of construction and engineering, the demand for reliable and sturdy materials is paramount. Among these materials, steel mesh has emerged as a critical component, widely used for reinforcing concrete structures, providing stability, and enhancing overall durability. The rise of steel mesh manufacturers has been a significant development in meeting this growing demand, reflecting advancements in technology, engineering practices, and material sciences.

What is Steel Mesh?

Steel mesh, also known as welded wire fabric or reinforcement mesh, consists of a network of steel wires that are welded together at various intervals. This sturdy mesh is typically embedded within concrete to provide tensile strength and support, helping structures withstand various forces, including tension, compression, and shear. It is a versatile product used in a variety of applications, including residential, commercial, and industrial buildings, as well as roads, tunnels, and bridges.

The Role of Steel Mesh Manufacturers

Steel mesh manufacturers play an essential role in the construction industry. They are responsible for producing high-quality steel mesh that meets specific industry standards and regulations. The manufacturing process involves various stages, including wire drawing, mesh fabrication, and quality control checks, ensuring that the final product meets the required specifications for strength, durability, and corrosion resistance.

Additionally, manufacturers often offer customized solutions to cater to the unique needs of different projects. These bespoke products can be tailored in terms of size, shape, and configuration, enabling builders and engineers to achieve optimal reinforcement for their specific applications. As a result, innovation in manufacturing processes has become a hallmark of leading steel mesh manufacturers.

Advancements in Steel Mesh Manufacturing

Innovation is at the heart of the steel mesh manufacturing sector. Advanced technologies such as automated welding systems, high-precision cutting tools, and computer-aided design (CAD) software have revolutionized the production process, allowing manufacturers to increase efficiency and reduce material waste. These technologies not only improve the quality of the steel mesh but also enhance the overall productivity of manufacturers, enabling them to meet the increased demands of the construction industry.

steel mesh manufacturers

Moreover, the emergence of eco-friendly manufacturing practices has gained momentum in recent years. Many steel mesh manufacturers are exploring sustainable methods of production, such as recycling scrap steel and using energy-efficient processes. This shift aligns with the growing emphasis on sustainability and environmental responsibility within the construction sector.

The Global Market for Steel Mesh

The global market for steel mesh is witnessing significant growth, driven by rapid urbanization, infrastructure development, and an increase in construction activities worldwide. Countries in Asia-Pacific, North America, and Europe are leading in steel mesh consumption, with emerging economies in Asia expected to contribute substantially to future demand. The rise of mega-cities and the need for durable infrastructure in developing regions are key factors propelling the market expansion.

Furthermore, as construction projects grow in complexity, the reliance on advanced materials like steel mesh becomes more pronounced. Builders and contractors increasingly recognize the importance of using high-quality reinforcement materials to ensure the longevity and safety of their structures. This trend further underscores the pivotal role of steel mesh manufacturers in the construction supply chain.

Challenges and Opportunities

While the future looks promising for steel mesh manufacturers, there are challenges to navigate. Fluctuating raw material prices, stringent environmental regulations, and competition from alternative reinforcement products pose significant hurdles. However, these challenges also present opportunities for innovation and growth. Manufacturers that invest in research and development to create stronger, lighter, and more sustainable steel mesh products will likely gain a competitive edge in the market.

Conclusion

In conclusion, steel mesh manufacturers are vital contributors to the construction industry, providing essential materials that enhance the safety and durability of structures worldwide. With ongoing advancements in technology, a commitment to sustainability, and a focus on meeting the ever-evolving needs of the marketplace, these manufacturers are poised to play an even more significant role in shaping the future of construction. As the demand for robust infrastructure continues to grow, so too will the importance of high-quality steel mesh and the manufacturers behind it.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025