-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

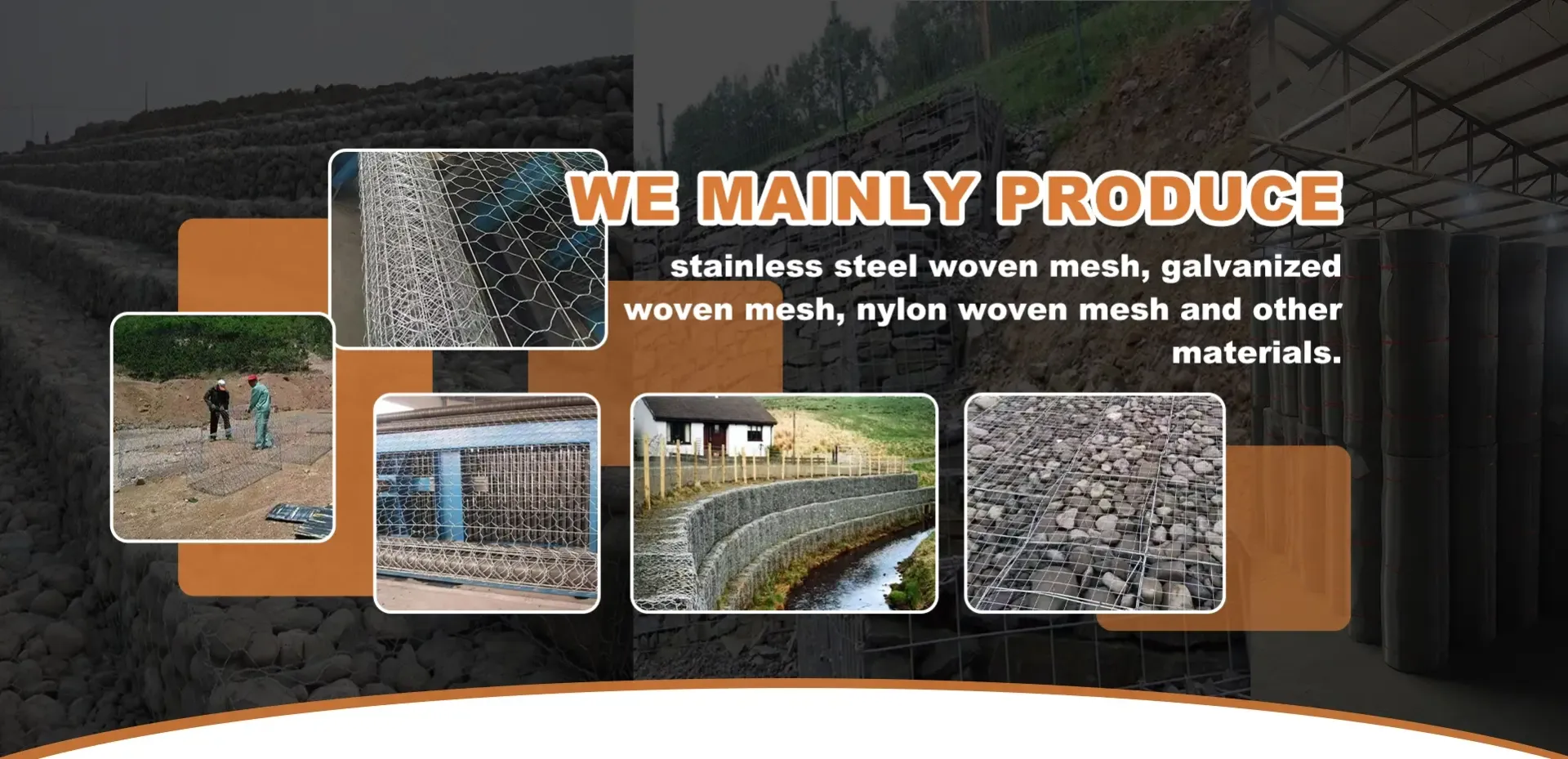

steel mesh manufacturers

The Role of Steel Mesh Manufacturers in Modern Construction

In the ever-evolving construction industry, the demand for high-quality materials is pivotal to ensuring the durability, strength, and safety of structures. Among these materials, steel mesh stands out as a vital element used across various applications, from concrete reinforcement to fencing solutions. The role of steel mesh manufacturers, therefore, becomes crucial in maintaining the integrity of architectural designs and infrastructure development.

Steel mesh, typically made from high-tensile steel wires, is designed to enhance the load-bearing capacity of concrete. It acts as a reinforcement framework that helps to prevent cracks and structural failures, which can be caused by various factors such as tension, compression, and shifts in the ground. By utilizing steel mesh, construction projects not only benefit from increased strength but also improved resilience against environmental challenges.

One of the primary advantages of collaborating with reputable steel mesh manufacturers is the assurance of quality compliance. Established manufacturers follow stringent industry standards that govern the production processes and material specifications. This adherence to quality standards guarantees that the steel mesh can withstand rigorous testing and meet the demands of various building codes. Moreover, many manufacturers also invest in advanced technologies and machinery to produce mesh that meets specific customer requirements, covering diverse applications such as residential, commercial, and industrial projects.

steel mesh manufacturers

Sustainability is another key consideration driving innovations in the steel mesh manufacturing sector. As the construction industry becomes increasingly focused on reducing its carbon footprint, manufacturers are exploring eco-friendly practices in sourcing raw materials and streamlining production processes. This shift not only contributes to environmental protection but also appeals to clients and stakeholders who prioritize sustainable building methods.

Furthermore, steel mesh manufacturers often provide tailored solutions to meet the specific needs of their clients. This customization can include different mesh sizes, wire gauges, and coatings to enhance corrosion resistance. By understanding the unique requirements of each project, manufacturers play a vital role in ensuring that the end product aligns with the design and functionality of the structure.

In addition to product quality, steel mesh manufacturers typically offer extensive support services, including consultation and technical assistance. Their expertise can prove invaluable during the planning and execution phases of construction projects. By working closely with architects, engineers, and contractors, manufacturers can provide insights on the most suitable mesh types and configuration for particular applications, thereby optimizing performance and safety.

In conclusion, steel mesh manufacturers are integral to the construction industry's fabric, providing essential materials that enhance the strength and longevity of structures. Their commitment to quality, sustainability, and customer-focused solutions positions them as key partners in achieving successful construction outcomes. As the industry continues to grow, the role of these manufacturers will be vital in navigating the challenges and demands of modern construction, ensuring that our built environment is safe, resilient, and sustainable for future generations.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025