-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Feb . 17, 2025 12:06

Back to list

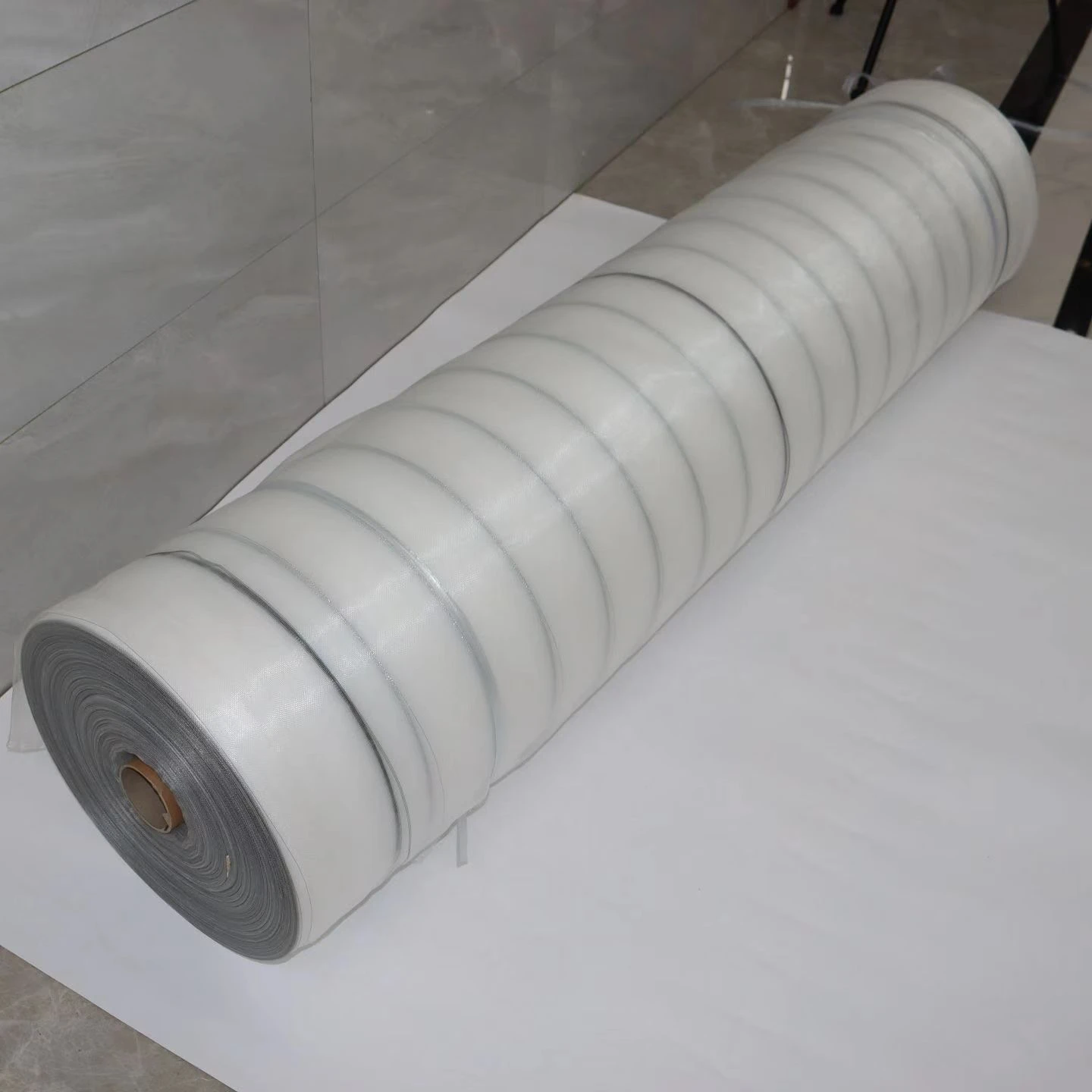

bird mesh netting

Steel netting mesh, a versatile and robust solution, has become integral in various industrial and residential applications. Its adoption is driven by unique attributes including durability, strength, and multifaceted utility. Leveraging these properties requires a deep dive into the practical experiences, technical expertise, authoritative insights, and credibility that surround its use.

The authoritative perspective on steel netting mesh is heavily supported by industry standards and guidelines. Compliance with international standards like ASTM and ISO confirms its quality and reliability. Engaging with these standards fosters trust in its application, ensuring that products meet rigorous quality checks. Furthermore, the versatility of steel netting mesh is continuously explored in academic research, with studies demonstrating its resistance to corrosion through innovative galvanization techniques. Such insights advocate for its expanded usage, impelled by empirical evidence from authoritative sources. Trustworthiness, a cornerstone of steel netting mesh's sustained popularity, is evidenced by consistent testimonials from industry leaders and practitioners. Companies specializing in construction materials frequently provide certifications that bolster consumer confidence. These certificates often indicate the mesh's adherence to safety and quality standards, reinforcing trust among users. It's also worth noting manufacturers' efforts in sustainable sourcing and environmentally friendly production processes, which further enhance product credibility. Testimonials from large-scale projects attest to its efficacy, with clients endorsing it as a reliable and cost-effective solution. In conclusion, steel netting mesh stands out as a multi-purpose, high-performance material. Its real-world applications, backed by technical expertise and authoritative guidelines, position it as a top choice across industries. The convergence of practical experiences, meticulous production standards, and transparent communication bolsters its trustworthiness. Consequently, it doesn't just fulfill functional requirements but also aligns with the quality expectations of modern engineering and architectural projects. As industries evolve, steel netting mesh promises to adapt and remain a cornerstone of quality and reliability.

The authoritative perspective on steel netting mesh is heavily supported by industry standards and guidelines. Compliance with international standards like ASTM and ISO confirms its quality and reliability. Engaging with these standards fosters trust in its application, ensuring that products meet rigorous quality checks. Furthermore, the versatility of steel netting mesh is continuously explored in academic research, with studies demonstrating its resistance to corrosion through innovative galvanization techniques. Such insights advocate for its expanded usage, impelled by empirical evidence from authoritative sources. Trustworthiness, a cornerstone of steel netting mesh's sustained popularity, is evidenced by consistent testimonials from industry leaders and practitioners. Companies specializing in construction materials frequently provide certifications that bolster consumer confidence. These certificates often indicate the mesh's adherence to safety and quality standards, reinforcing trust among users. It's also worth noting manufacturers' efforts in sustainable sourcing and environmentally friendly production processes, which further enhance product credibility. Testimonials from large-scale projects attest to its efficacy, with clients endorsing it as a reliable and cost-effective solution. In conclusion, steel netting mesh stands out as a multi-purpose, high-performance material. Its real-world applications, backed by technical expertise and authoritative guidelines, position it as a top choice across industries. The convergence of practical experiences, meticulous production standards, and transparent communication bolsters its trustworthiness. Consequently, it doesn't just fulfill functional requirements but also aligns with the quality expectations of modern engineering and architectural projects. As industries evolve, steel netting mesh promises to adapt and remain a cornerstone of quality and reliability.

Latest news

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025