-

Afrikaans

Afrikaans -

Albanian

Albanian -

Amharic

Amharic -

Arabic

Arabic -

Armenian

Armenian -

Azerbaijani

Azerbaijani -

Basque

Basque -

Belarusian

Belarusian -

Bengali

Bengali -

Bosnian

Bosnian -

Bulgarian

Bulgarian -

Catalan

Catalan -

Cebuano

Cebuano -

China

China -

Corsican

Corsican -

Croatian

Croatian -

Czech

Czech -

Danish

Danish -

Dutch

Dutch -

English

English -

Esperanto

Esperanto -

Estonian

Estonian -

Finnish

Finnish -

French

French -

Frisian

Frisian -

Galician

Galician -

Georgian

Georgian -

German

German -

Greek

Greek -

Gujarati

Gujarati -

Haitian Creole

Haitian Creole -

hausa

hausa -

hawaiian

hawaiian -

Hebrew

Hebrew -

Hindi

Hindi -

Miao

Miao -

Hungarian

Hungarian -

Icelandic

Icelandic -

igbo

igbo -

Indonesian

Indonesian -

irish

irish -

Italian

Italian -

Japanese

Japanese -

Javanese

Javanese -

Kannada

Kannada -

kazakh

kazakh -

Khmer

Khmer -

Rwandese

Rwandese -

Korean

Korean -

Kurdish

Kurdish -

Kyrgyz

Kyrgyz -

Lao

Lao -

Latin

Latin -

Latvian

Latvian -

Lithuanian

Lithuanian -

Luxembourgish

Luxembourgish -

Macedonian

Macedonian -

Malgashi

Malgashi -

Malay

Malay -

Malayalam

Malayalam -

Maltese

Maltese -

Maori

Maori -

Marathi

Marathi -

Mongolian

Mongolian -

Myanmar

Myanmar -

Nepali

Nepali -

Norwegian

Norwegian -

Norwegian

Norwegian -

Occitan

Occitan -

Pashto

Pashto -

Persian

Persian -

Polish

Polish -

Portuguese

Portuguese -

Punjabi

Punjabi -

Romanian

Romanian -

Russian

Russian -

Samoan

Samoan -

Scottish Gaelic

Scottish Gaelic -

Serbian

Serbian -

Sesotho

Sesotho -

Shona

Shona -

Sindhi

Sindhi -

Sinhala

Sinhala -

Slovak

Slovak -

Slovenian

Slovenian -

Somali

Somali -

Spanish

Spanish -

Sundanese

Sundanese -

Swahili

Swahili -

Swedish

Swedish -

Tagalog

Tagalog -

Tajik

Tajik -

Tamil

Tamil -

Tatar

Tatar -

Telugu

Telugu -

Thai

Thai -

Turkish

Turkish -

Turkmen

Turkmen -

Ukrainian

Ukrainian -

Urdu

Urdu -

Uighur

Uighur -

Uzbek

Uzbek -

Vietnamese

Vietnamese -

Welsh

Welsh -

Bantu

Bantu -

Yiddish

Yiddish -

Yoruba

Yoruba -

Zulu

Zulu

Steel Screening Techniques for Enhanced Material Separation and Processing Efficiency

The Importance of Steel Screening in Modern Industries

Steel screening is a vital process utilized in various industries to separate materials based on size and shape. This technique involves the use of screens made of steel, which are engineered to withstand the rigors of the industrial environment while providing efficient filtration and separation.

The Basics of Steel Screening

At its core, steel screening is designed to segregate particles or materials. In many manufacturing processes, raw materials need to be sifted to ensure that only those of a specific size proceed to the next phase of production. This is crucial in industries such as mining, construction, and recycling, where uniformity in material size can significantly affect the quality of the final product.

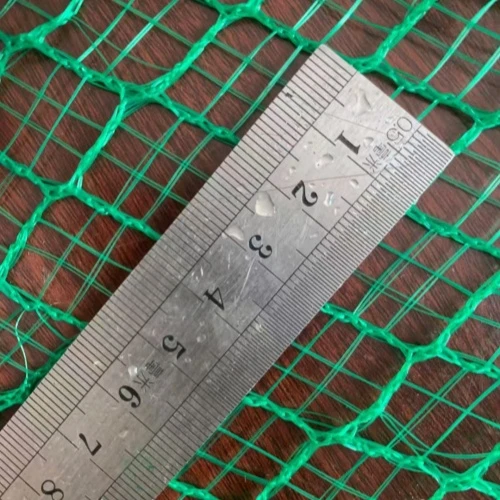

The design of steel screens can vary significantly based on the application. They can come in various mesh configurations, ranging from fine screens that trap almost every particle to coarse screens that allow larger materials to pass through. The choice of screening type is influenced by factors such as the type of material being processed, the desired size of the separated product, and the specific requirements of subsequent production processes.

Applications Across Industries

Steel screening finds applications in a multitude of fields

1. Mining and Mineral Processing In the mining industry, steel screens are essential for separating mineral ores from unwanted materials. The screening process ensures that miners can efficiently extract valuable nuggets and avoid the inefficiencies caused by larger, unprocessed materials.

2. Construction In construction, aggregates such as sand, gravel, and crushed stone are often screened to achieve the desired consistency and size. This helps in ensuring that the materials meet industry standards required for various construction applications, from concrete production to road building.

3. Waste Management and Recycling Steel screening plays a critical role in waste processing and recycling facilities. Here, various waste materials are screened to separate recyclables from non-recyclables, making the recycling process more efficient. By screening out contaminants, facilities can enhance the quality of recyclable materials, ensuring that they are acceptable for reuse.

steel screening

4. Food Processing In food manufacturing, steel screens are used to ensure that impurities and oversized particles are removed from raw materials. This is particularly important in industries like milling and grain processing, where product quality directly impacts safety and consumer satisfaction.

Benefits of Steel Screening

The benefits of implementing steel screening in industrial processes are numerous

- Enhanced Quality Control By using steel screens to filter out unwanted materials, companies can enhance the quality of both raw materials and finished products. This leads to lower failure rates and higher overall quality.

- Increased Efficiency Screening helps streamline various processes by ensuring that only the right-sized materials move on to subsequent stages of production. This minimizes waste, saves time, and optimizes resource utilization.

- Durability and Longevity Steel screens are engineered for durability, resisting wear and tear from abrasive materials and high volumes of usage. This longevity leads to lower maintenance costs and fewer replacements, contributing to overall operational efficiency.

- Adaptability Steel screening technology can be customized to meet the specific needs of different industries and applications. Whether it involves adjusting the mesh size or designing screens that can handle varying load capacities, adaptability is a key feature of modern screening technologies.

The Future of Steel Screening

Looking ahead, the future of steel screening is closely tied to advancements in technology. Innovations in materials science and automation are expected to further enhance the efficiency and effectiveness of steel screening systems. For instance, the integration of smart technologies can enable real-time monitoring of screening processes, allowing for better adjustments and more responsive production techniques.

In conclusion, steel screening is an essential component across many industries, ensuring efficient material separation and quality management. As technology continues to evolve, so too will the methods and applications of steel screening, solidifying its role as a cornerstone in modern industrial processes. Whether in mining, construction, recycling, or food processing, steel screening remains a pivotal technique for fostering efficiency and quality in production lines worldwide.

-

Shipping Plastic Bags for Every NeedNewsJul.24,2025

-

Safety Netting: Your Shield in ConstructionNewsJul.24,2025

-

Plastic Mesh Netting for Everyday UseNewsJul.24,2025

-

Nylon Netting for Every UseNewsJul.24,2025

-

Mesh Breeder Box for Fish TanksNewsJul.24,2025

-

Expanded Steel Mesh Offers Durable VersatilityNewsJul.24,2025